Anti-flooding intermediate coating and method for preparing same

A floating color and main color technology, used in coatings, polyester coatings, etc., can solve the problems of blooming, large color differences, unstable production, etc., and achieve the effects of improved precipitation, improved floating color, and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

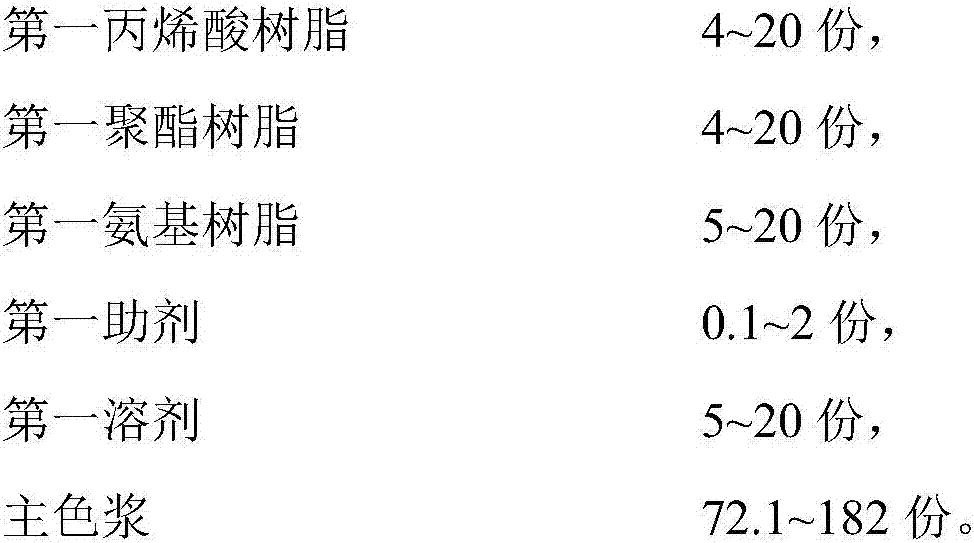

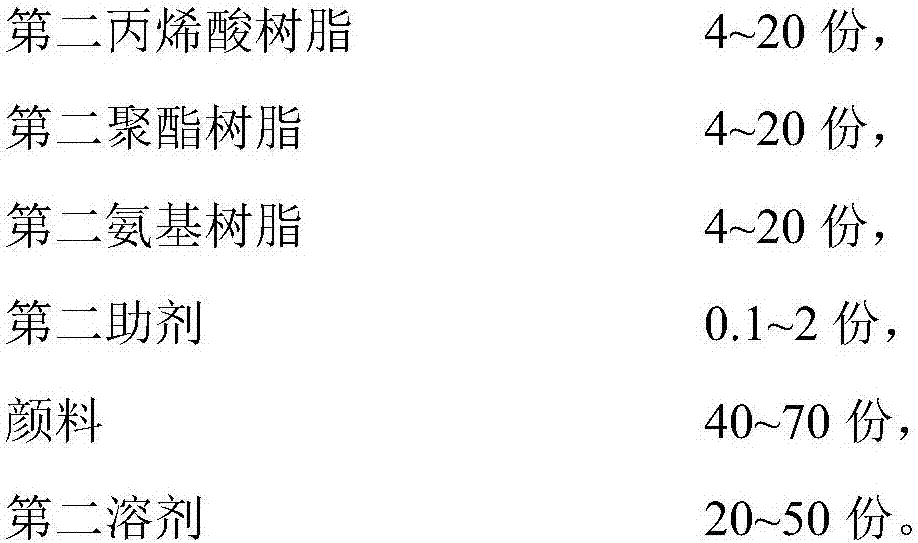

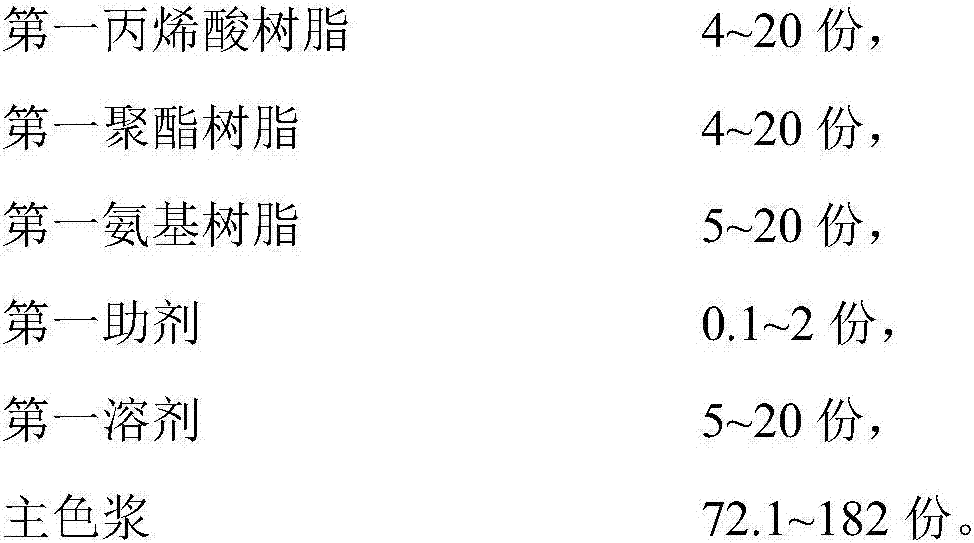

[0045] A preparation method for anti-floating paint, comprising the following steps:

[0046] Prepare the main color paste:

[0047] Add 10 parts of acrylic resin PRS-1015, 5 parts of polyester resin BECKOLITE AF-1378- 65X, 2 parts of BYK-161 and 60 parts of pigment titanium dioxide R-2196, after mixing, use sanding beads for sanding, mixing to control the KU viscosity within 80-100, the temperature of the coating during sanding should not exceed 60 degrees Celsius, and control the final The fineness reaches below 5 μm, and after sanding, filter, and calculate the amount of amino resin BR-20SE to be diluted by the yield. The yield of the middle coating system described in this embodiment is 70%, and the amino resin BR-20SE The addition amount is 5 parts, and then the main color paste is obtained by mixing uniformly; preferably, the main color paste prepared in this implementation is the anti-floating intermediate coating white main color paste (white intermediate coating semi...

Embodiment 2

[0068] A preparation method for anti-floating paint, comprising the following steps:

[0069] Prepare the main color paste:

[0070] Add 20 parts of acrylic resin PRS-1015, 7 parts of polyester resin BECKOLITE AF-1378- 65X, 0.1 part of BYK-161 and 70 parts of pigment titanium dioxide R-2196, after mixing, use sanding beads for sanding, mixing to control the KU viscosity within 80-100, the temperature of the coating during sanding should not exceed 60 degrees Celsius, and control the final The fineness is less than 5 μm, and it is filtered after sanding, and the amount of amino resin BR-20SE to be diluted is calculated by the yield. In this embodiment, the yield of the intermediate coating system is 70%, and 15 parts of amino resin BR-20SE is added 20SE is diluted and mixed uniformly to obtain the main color paste; preferably, the main color paste prepared in this implementation is the anti-floating intermediate coating white main color paste (white intermediate coating semi-f...

Embodiment 3

[0074] A preparation method for anti-floating paint, comprising the following steps:

[0075] Prepare the main color paste:

[0076] Add 15 parts of acrylic resin PRS-1015, 10 parts of polyester resin BECKOLITE AF-1378- 65X, 1 part of BYK-161 and 65 parts of pigment titanium dioxide R-2196, after mixing, use sanding beads for sanding, mixing to control the KU viscosity within 80-100, the temperature of the coating during sanding should not exceed 60 degrees Celsius, and control the final The fineness is less than 5 μm, after sanding, filter, and calculate the amount of amino resin BR-20SE to be diluted according to the yield. In this embodiment, the yield of the intermediate coating system is 70%, adding 10 parts of amino resin BR-20SE 20SE is diluted and mixed uniformly to obtain the main color paste; preferably, the main color paste prepared in this implementation is the anti-floating intermediate coating white main color paste (white intermediate coating semi-finished prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com