A method for treating antimony-containing sulfide ore

A technology for antimony sulfide ore and slurry is applied in the field of cyclone electrolytic leaching to directly treat antimony sulfide ore, which can solve the problems of inconvenient replacement of electrolyte and slurry, not using cyclone electrolysis, affecting the degree of reaction progress, and the like. The effect of reducing cost and energy consumption, eliminating concentration polarization, and efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

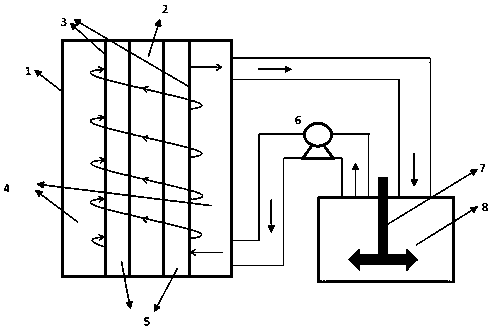

Image

Examples

Embodiment 1

[0032] The experimental raw material in this example is a certain high-grade stibnite in western Hunan, and the contents of each element in the mineral are: Sb40.34%, Fe9.53%, S19.07%. Has a high recycling value.

[0033] The method for processing antimony-containing sulfide ore of the present embodiment comprises the following steps:

[0034] (1) Grinding the stibnite into a material with a particle size of less than 74 μm to obtain mineral powder; mixing dilute hydrochloric acid solution and mineral powder at a liquid-solid volume mass ratio of 6ml:1g to obtain a slurry;

[0035] Described dilute hydrochloric acid concentration is 150g / L;

[0036] (2) Put the slurry in the slurry tank, and the slurry enters the swirl electrolysis system through a pneumatic pump (the feeding speed of the slurry is 0.5L / min) for swirl electrolysis. The conditions for swirl electrolysis are: temperature 75°C, the cathode current density is 159A / m 2 . After electrolysis, the slurry re-enters...

Embodiment 2

[0040] The experimental raw material in this example is a certain antimony-containing pyrite in western Hunan, and the contents of each element in the mineral are: Sb4.2%, Fe19.8%, S18.1%. Has a high recycling value.

[0041] The method for processing antimony-containing sulfide ore of the present embodiment comprises the following steps:

[0042] (1) Grinding antimony-containing pyrite into materials with a particle size of less than 74 μm to obtain mineral powder; mixing dilute hydrochloric acid solution and mineral powder at a liquid-solid volume mass ratio of 8 ml:1 g to obtain a slurry;

[0043] Described dilute hydrochloric acid concentration is 150g / L;

[0044](2) Put the slurry in the slurry tank, and the slurry enters the swirl electrolysis system through a pneumatic pump (the feeding speed of the slurry is 0.5L / min) for swirl electrolysis. The conditions for swirl electrolysis are: temperature 75°C, the cathode current density is 159A / m 2 . After electrolysis, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com