Wear-resisting coating of YAG/8YSZ dual ceramic layer structure and plasma preparation method

A heat-resistant coating and plasma technology, used in coatings, metal material coating processes, air transportation, etc., can solve the problem that thermal barrier coatings cannot provide sufficient protection for metal oxygen gun tips, and achieve good high temperature resistance. The effect of oxidation protection, improving production efficiency and reducing production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

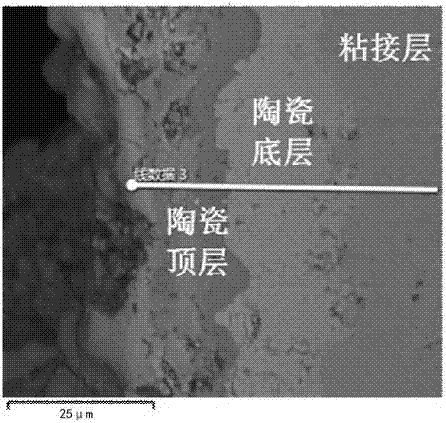

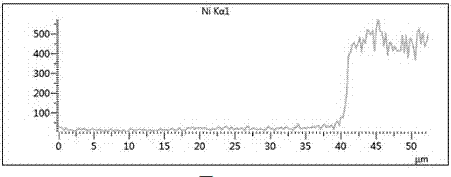

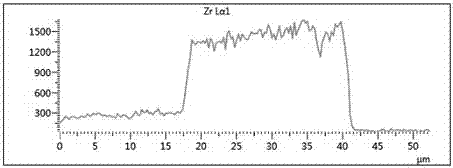

[0018] The present invention is a YAG / 8YSZ double-ceramic layer structure heat-resistant coating and its preparation method. The YAG / 8YSZ double-ceramic layer structure heat-resistant coating has the following structure: the bonding layer is NiCoCrAlY, the ceramic bottom layer is 8YSZ, and the ceramic top layer is YAG .

[0019] YAG / 8YSZ double ceramic layer structure heat-resistant coating plasma preparation method, the steps are:

[0020] (1) Pretreatment of spraying materials: Before spraying, the three powders are vacuum-dried respectively;

[0021] (2) Substrate surface pretreatment: Before spraying, the substrate is polished, cleaned and sandblasted;

[0022] (3) Substrate surface preheating: before spraying, preheat the substrate surface;

[0023] (4) Adhesive layer preparation and cooling: NiCoCrAlY powder is used to prepare an adhesive layer on the preheated substrate by plasma spraying technology; then the coating surface is air-cooled;

[0024] (5) Preparation an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com