A material for artificial hearth of aluminum electrolytic cell and preparation of said artificial hearth

An aluminum electrolytic cell, artificial technology, applied in the field of refractory materials, can solve the problems of deformed furnace, electrolyte pollution, low current efficiency, etc., and achieve the effect of avoiding sinking and avoiding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

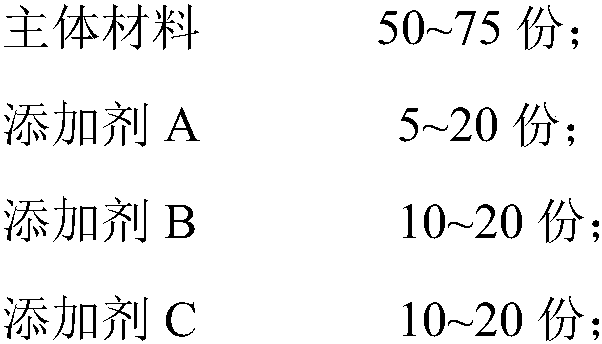

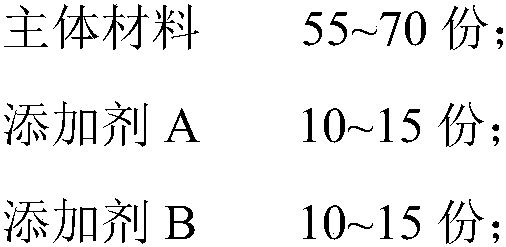

Method used

Image

Examples

Embodiment 1

[0085] Step (1): 300g of the host material (NaF: 50g, LiF: 30g, Na 3 AlF 6 : 200g, Li 3 AlF 6 : 20g) and 75g additive A (BaF 2 : 20g, CaF 2 : 40g, MgF 2 : 15g) ground to -200 mesh accounted for 75% and mixed evenly;

[0086] Step (2): Heat the homogeneously mixed material in step (1) to 900°C and keep it warm for 90 minutes to completely melt it;

[0087] Step (3): 62g additive B (Al 2 o 3 Powder: 51g, AlF 3 : 11g) ground with 63g additive C (MgO fiber: 11g, Al 2 o 3 Fiber: 52g) mix evenly, fill in the mould;

[0088]Step (4): placing the mold filled in step (3) at 450°C for heat preservation;

[0089] Step (5): pour the mixed melt obtained in step (2) into the mold filled with additive B and additive C in step (4), and keep stirring to make it mix with the material in the mold until it becomes viscous, and then Then rapidly cool to room temperature within 20 minutes.

[0090] The density of this material is 2.42g / cm 3 , The material withstands a maximum tempera...

Embodiment 2

[0100] Step (1): 288g host material (NaF: 72g, LiF: 18g, NaF: 3 AlF 6 : 162g, Li 3 AlF 6 : 36g) and 65g additive A (BaF 2 : 26g, CaF 2 : 22g, MgF 2 : 17g) ground to -200 mesh accounted for 80% and mixed evenly;

[0101] Step (2): Heat the homogeneously mixed material in step (1) to 1000°C, keep it warm for 50 minutes to completely melt it;

[0102] Step (3): 75g additive B (Al 2 o 3 Powder: 50g, AlF 3 : 25g) ground with 72g additive C (MgO fiber: 24g, Al 2 o 3 Fiber: 48g) mix evenly, fill in the mould;

[0103] Step (4): placing the mold filled in step (3) at 500°C for heat preservation;

[0104] Step (5): pour the mixed melt obtained in step (2) into the mold filled with additive B and additive C in step (4), and keep stirring to make it mix with the material in the mold until it becomes viscous, and then Then rapidly cool to room temperature within 20 minutes.

[0105] The density of this material is 2.56g / cm 3 , withstand the highest temperature of 1050 ° C, ...

Embodiment 3

[0131] Step (1): 350g of the host material (NaF: 53g, LiF: 35g, NaF: 3 AlF 6 : 240g, Li 3 AlF 6 : 22g) and 50g additive A (BaF 2 : 12g, CaF 2 : 27g, MgF 2 : 11g) ground to -200 mesh accounted for 90% and mixed evenly;

[0132] Step (2): Heat the homogeneously mixed material in step (1) to 1100°C and keep it warm for 30 minutes to completely melt it;

[0133] Step (3): 50g additive B (Al 2 o 3 Powder: 37.5g, AlF 3 : 12.5g) ground with 50g additive C (MgO fiber: 12.5g, Al 2 o 3 Fiber: 37.5g) mixed evenly, filled in the mould;

[0134] Step (4): placing the mold filled in step (3) at 550°C for heat preservation;

[0135] Step (5): pour the mixed melt obtained in step (2) into the mold filled with additive B and additive C in step (4), and keep stirring to make it mix with the material in the mold until it becomes viscous, and then Then rapidly cool to room temperature within 20 minutes.

[0136] The density of this material is 2.33g / cm 3 , withstand the highest tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com