Defluorination agent and application thereof

A technology of medicament and coagulant aid, applied in water pollutants, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve high investment and operation costs, frequent and complicated regeneration and backwashing, and is not suitable for industrial Wastewater and other problems, achieve the effect of fast fluoride removal, good fluoride removal effect, and elimination of electrostatic repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A fluoride removal agent composed of the following components in mass fractions: 40% desulfurization sludge, 20% ferrous sulfate heptahydrate, 10% polyferric sulfate, 3% activated silicate, 15% lanthanum chloride, 12% lanthanum nitrate .

[0028] Mix the ingredients of the formula (the desulfurization sludge is solid waste from steel mills, and the others are commercially available products) to prepare an efficient defluorinating agent;

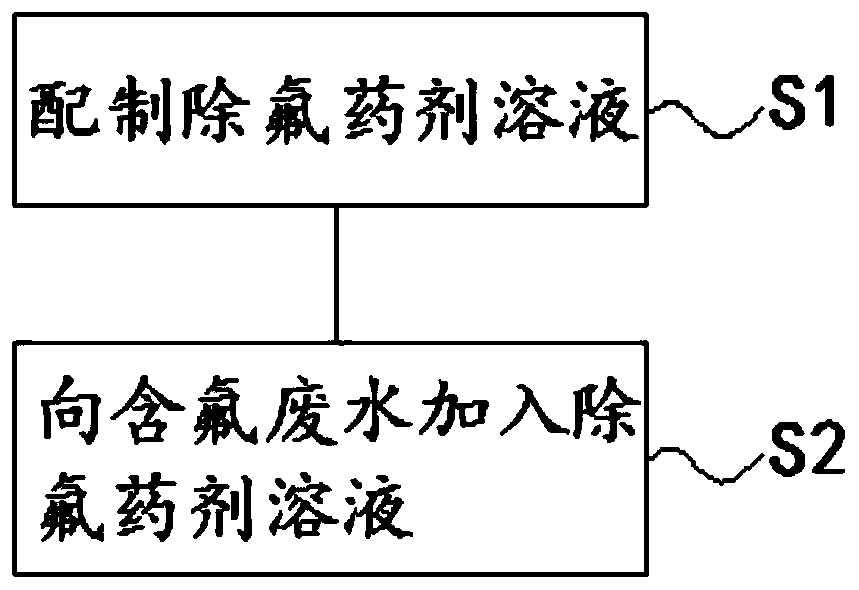

[0029] See figure 1 , Take phenol cyanide wastewater from a steel plant as the fluorine-containing wastewater to be treated. The pH of the fluorine-containing wastewater to be treated is 7.80 and the fluoride ion concentration is 36mg / L. The prepared defluorinating agent SGDF1 is used to treat the fluorine-containing wastewater. To investigate the fluoride removal effect of the fluoride removal agent, the specific steps are as follows:

[0030] (1) Dissolve 1 mg of the prepared defluorinating agent in deionized water to prepare a solution w...

Embodiment 2

[0033] A fluoride removal agent consisting of the following components in mass fractions: 40% desulfurized sludge, 20% ferrous sulfate heptahydrate, 10% polymeric ferric sulfate, 3% activated silicic acid, 20% lanthanum chloride, 7% lanthanum nitrate .

[0034] Mix the ingredients of the formula (all commercially available products) uniformly to prepare a fluoride removal agent;

[0035] Take continuous casting turbid circulating water from a steel plant as the fluorine-containing wastewater to be treated. The pH of the fluorine-containing wastewater to be treated is 7.90 and the fluoride ion concentration is 45mg / L. The prepared defluorinating agent SGDF1 is used to treat the fluorine-containing wastewater. Perform treatment to investigate the fluoride removal effect of the fluoride removal agent. The specific steps are as follows:

[0036] (1) Dissolve 1 mg of the prepared defluorinating agent in deionized water to prepare a solution with a mass fraction of 10 wt%; prepare 1 part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com