Preparation and regeneration method of a defluoridation material based on coal-based coke powder

A technology of coal-based coke powder and fluorine materials, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorption water/sewage treatment, etc. Occupancy and other problems, to achieve the effect of large amount of fluorine removal, prolonging service life and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

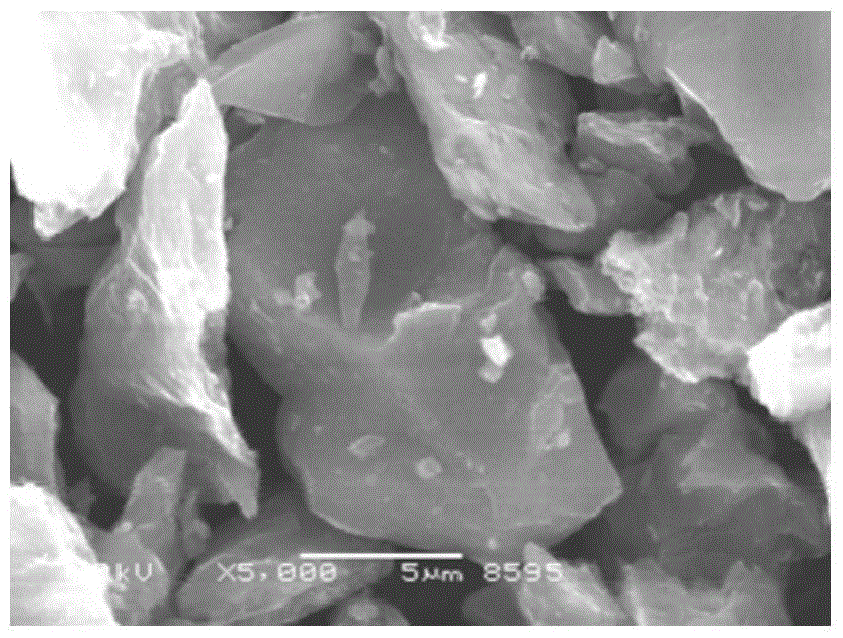

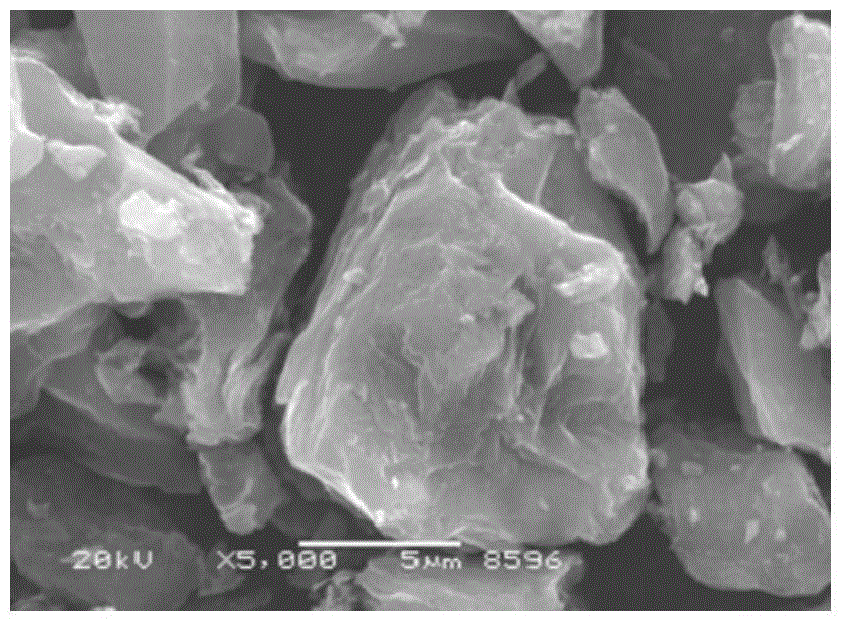

Image

Examples

Embodiment 1

[0042] Preparation and regeneration of defluoridation material for coal coke powder activated by water vapor

[0043] (1) Preparation of fluoride removal material

[0044] The first step: pre-oxidation treatment of coal-based coke powder

[0045] The coal-based coke powder that is about to be crushed below 20um is mixed with the pre-oxidant potassium nitrate of 20wt% by weight of the coal-based coke powder, and the same volume of water as the coal-based coke powder is added to form a slurry, which is placed in a high-temperature furnace After heat preservation at 400°C for 2 hours, cool naturally to obtain pre-oxidized coal-based coke powder.

[0046] The second step: activation treatment of pre-oxidized coal-based coke powder

[0047]Raise the temperature of the pre-oxidized coal-based coke powder to 750°C at a rate of 5°C / min under the protection of nitrogen, and then pass in water vapor at this temperature for 90 minutes, then cool with the furnace under the protection of...

Embodiment 2

[0071] Preparation and regeneration of fluoride-removing material for activated coal coke powder with potassium hydroxide

[0072] (1) Preparation of fluoride removal material

[0073] The first step: pre-oxidation treatment of coal-based coke powder

[0074] The coal-based coke powder that is about to be crushed below 20um is mixed with potassium permanganate with a mass of 20wt% of the coal-based coke powder, and the same volume of water as the coal-based coke powder is added to form a slurry, which is placed in a high-temperature furnace After heat preservation at 600°C for 1 hour, cool naturally to obtain pre-oxidized coal-based coke powder.

[0075] The second step: activation treatment of pre-oxidized coal-based coke powder

[0076] Mix potassium hydroxide 5 times the weight of pre-oxidized coal-based coke powder with the pre-oxidized coal-based coke powder, then heat the mixture to 750 °C at a rate of 5 °C / min, keep it warm for 60 min, and wash with water to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com