High-efficiency polyolefin/polyester sheath-core composite direct spinning system and method

A composite spinning and spinning system technology, applied in the fields of polymer chemical industry and chemical fiber, can solve the problems of inability to achieve end-use performance, unfavorable industrial chain energy consumption reduction, unfavorable composite fiber product quality stability and improvement, etc. Tight, strong adhesion, fast fiber forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

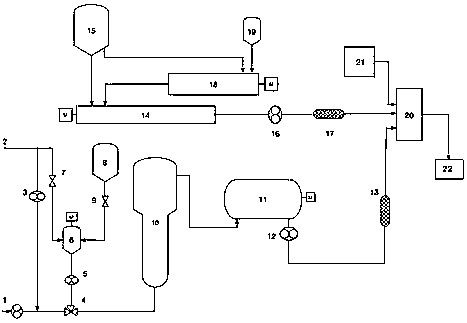

[0039] Such as figure 1 As shown, the high-efficiency polyolefin / polyester sheath-core composite direct spinning system includes a polyester synthesis system, a polyolefin melting system, a composite spinning box 20, a plasma generating device 21 and a spinning tube 22;

[0040]The polyester synthesis system includes a delivery pump 1, a three-way valve 4, an upflow pre-condensation kettle 10, a horizontal single-cavity final polycondensation kettle 11, a discharge and booster pump 12, and a static stirring heat exchanger 13 connected in sequence. , finally connected to the composite spinning beam 20, the polyester synthesis system also includes ethylene glycol pipeline 2, a branch line of the ethylene glycol pipeline 2 is connected to the delivery pump 1 and the three-way valve 4 through the injection pump 3 On the pipeline, another branch line of the ethylene glycol pipeline 2 is connected to the blending tank 6 through the first metering valve 7, and the polyester synthesis...

Embodiment 2

[0045] High-efficiency polyolefin / polyester skin-core composite direct spinning method to produce PE / PET non-heavy metal hot air bonded skin-core composite staple fiber for nonwovens, the steps include:

[0046] (1) Part of the esterification liquid BHET is drawn from the esterification process of ordinary large-scale polyester equipment, and is directly transported to the upflow pre-condensation tank by the delivery pump through the three-way valve, as ethylene glycol for assisting the pre-condensation reaction from ethylene two The alcohol pipeline is drawn out, injected by the syringe pump into the pipeline connected to the delivery pump and the three-way valve to meet with BHET, and the other part of ethylene glycol drawn out from the ethylene glycol pipeline enters the blending tank by the valve to control the flow rate, and is used to blend ethylene glycol titanium , the high-concentration liquid ethylene glycol titanium enters the blending tank from the storage tank thro...

Embodiment 3

[0051] High-efficiency polyolefin / polyester sheath-core composite direct spinning method to produce PP / PET needle-punched thermally bonded asphalt-impregnated sheath-core composite short fibers for non-woven fabrics, the steps include:

[0052] (1) The esterification liquid BHET is directly transported to the upflow pre-condensation tank by the delivery pump through the three-way valve, and the ethylene glycol used to assist the pre-condensation reaction is drawn from the ethylene glycol pipeline and injected into the connection between the delivery pump and the three-way tank by the injection pump. The pipeline of the through valve merges with BHET, and the other part of ethylene glycol drawn from the ethylene glycol pipeline enters the blending tank through the valve to control the flow, and is used to mix ethylene glycol antimony. The high-concentration liquid ethylene glycol antimony is metered from the storage tank. The valve enters the blending tank, diluted with ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com