Vibration reduction and isolation system for high-speed centrifugal extractor

A centrifugal extractor, vibration and vibration isolation technology, applied in liquid solution solvent extraction, mechanical equipment, spring/shock absorber, etc., can solve the problems of dynamic imbalance, fatigue damage, cumulative error of rotating parts of centrifugal extractor, etc. Achieve the effect of reducing vibration, widening the structure type, and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

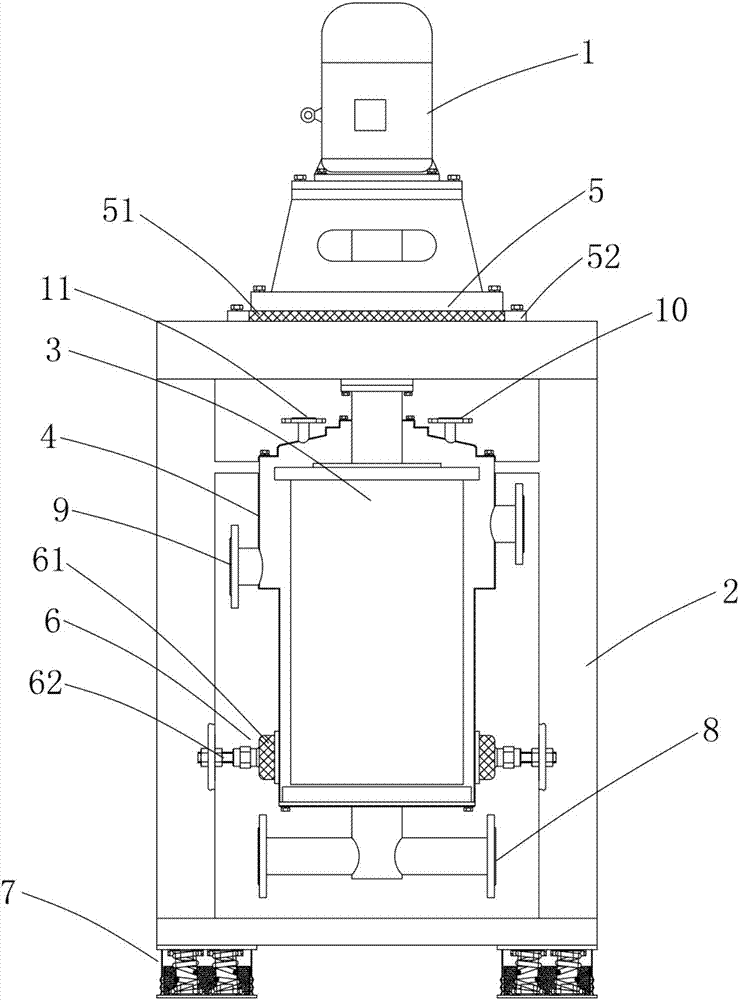

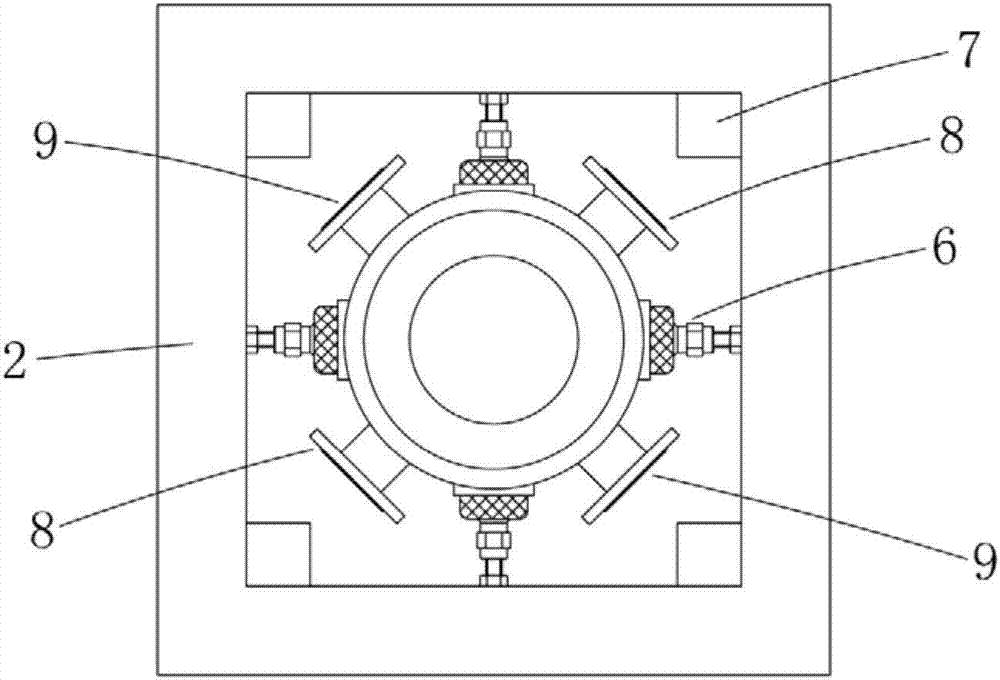

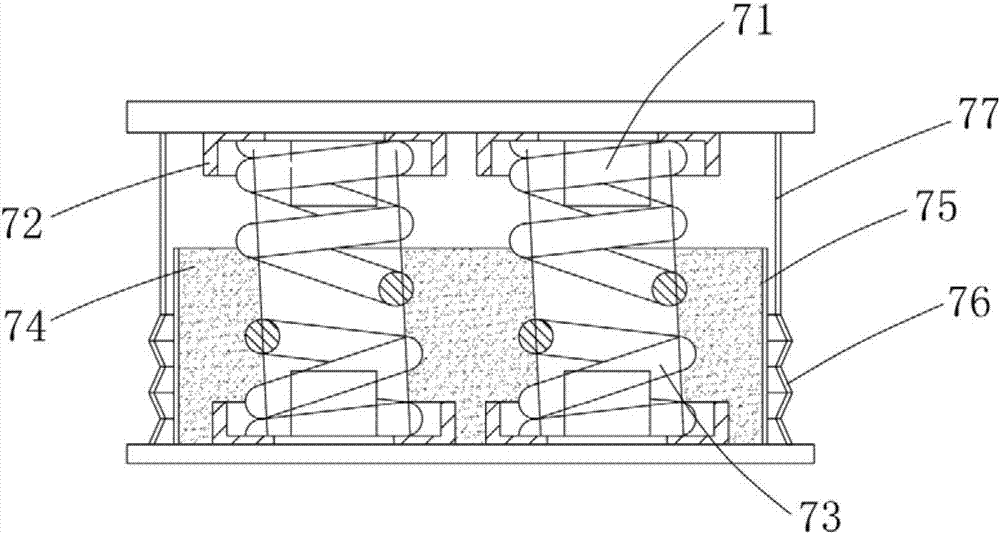

[0028] Embodiment: Referring to the accompanying drawings, the vibration reduction and vibration isolation system of the high-speed centrifugal extractor of this embodiment:

[0029] It includes a transmission part 1, a frame 2, a rotating part 3, and an outer casing 4 of the rotating part. The transmission part 1 provides rotational power for the rotating part 3. The transmission part 1 is arranged on the top of the frame, and is generally composed of a motor, a coupling etc., the motor provides rotating power, and the coupling connects the motor and the rotating part 3.

[0030] figure 1 As shown, the rotating part 3 is suspended inside the frame 2, and an elastic shock absorber 5 is arranged on the top of the frame 2, and the upper part of the rotating part 3 is supported on the frame 2 by the elastic shock absorber 5;

[0031] During processing, the frame 2 supports the transmission part 1, the rotating part 3 and the outer casing (4) of the centrifugal extractor, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com