Multi-layer welding strip and battery piece conveying device

A technology for handling device and cell, applied in the field of solar cells, can solve the problems of low production efficiency and complex production process of photovoltaic cell components, and achieve the effects of improving production efficiency, simplifying production process and improving output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

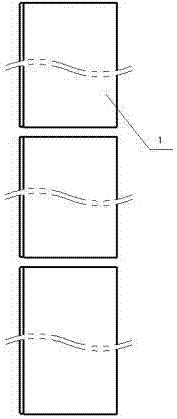

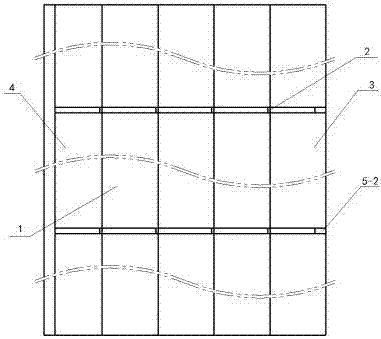

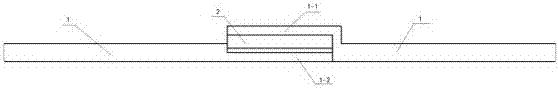

[0052] figure 1 It is a structural schematic diagram of a welding unit in a photovoltaic cell module; figure 2 is a structural schematic diagram of a photovoltaic cell module; image 3 It is a partial enlarged view of the junction of adjacent solar cells in a photovoltaic cell module; refer to Figure 1~3 , the photovoltaic cell assembly includes: 5 welding units arranged parallel to each other (that is, n=5, but n can also be other values greater than or equal to 2, such as: 2, 3, 4 or 6 etc.), each welding unit Each includes 3 solar cells 1 (that is, m=3, but m can also be other values greater than or equal to 2, such as: 2, 4, 5 or 6, etc.), and each solar cell in the welding unit 1 are located on the same plane and the length direction is in the same straight line;

[0053] The upper surface of one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com