Rose scented tea production method

A kind of rose tea, the technology of the production method, applied in the direction of tea treatment before extraction, etc., can solve the problems of insufficient opening of tea base leaves, small contact area of petals, weakened metabolism of petals, etc., so as to improve quality and appreciation value, increase exposure Surface area, effect of enhancing antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

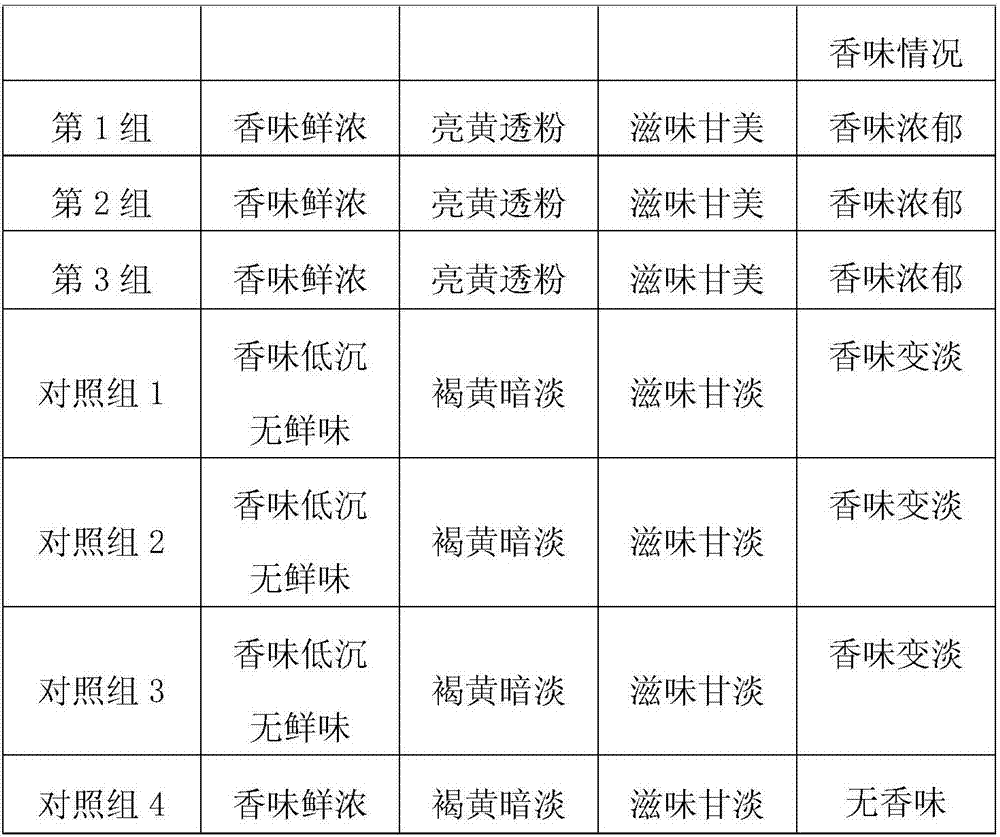

Embodiment 1

[0027] A kind of preparation method of rose tea of the present embodiment comprises the following steps:

[0028] (1) Picking of roses: pick when the roses are in buds and the buds are full. The picking time is in the morning on a sunny day. When picking, avoid mechanical damage to the flowers. in standby;

[0029] (2) Rose pretreatment: add the above-mentioned roses to the preservative solution and soak them for 5 minutes, then take them out and air-dry them until the water content is 80%, so as to obtain the processed roses, wherein the time from picking the roses to pretreatment is 60 minutes; Described fresh-keeping liquid is made by mixing vitamin C, vitamin E, potassium sorbate and water, and the weight ratio of described vitamin C, vitamin E, potassium sorbate and water is 5:3:1:100;

[0030] (3) Pretreatment of tea dhool: put the tea dhool in steam at 60°C for 70 seconds, take it out and dry it at 60°C until the water content is 4%, and cool the dried tea dhool to 2...

Embodiment 2

[0036] A kind of preparation method of rose tea of the present embodiment comprises the following steps:

[0037] (1) Picking of roses: pick when the roses are in buds and the buds are full. The picking time is in the morning on a sunny day. When picking, avoid mechanical damage to the flowers. in standby;

[0038] (2) Pretreatment of roses: adding the above-mentioned roses to the preservative solution and soaking them for 8 minutes, taking them out and air-drying until the water content is 85%, so as to obtain the processed roses, wherein the time from picking the roses to pretreatment is 120 minutes; Described fresh-keeping liquid is made by mixing vitamin C, vitamin E, potassium sorbate and water, and the weight ratio of described vitamin C, vitamin E, potassium sorbate and water is 9:6:3:200;

[0039] (3) Pretreatment of tea dhool: put the tea dhool in steam at 70°C for 40 seconds, take it out and dry it at 70°C until the water content is 4.5%, and cool the dried tea dh...

Embodiment 3

[0045] A kind of preparation method of rose tea of the present embodiment comprises the following steps:

[0046] (1) Picking of roses: pick when the roses are in buds and the buds are full. The picking time is in the morning on a sunny day. When picking, avoid mechanical damage to the flowers. in standby;

[0047] (2) Rose pretreatment: add the above-mentioned roses to the preservative solution and soak them for 7 minutes, then take them out and air-dry them until the water content is 83%, so as to obtain the processed roses, wherein the time from picking the roses to pretreatment is 80 minutes; Described fresh-keeping liquid is made by mixing vitamin C, vitamin E, potassium sorbate and water, and the weight ratio of described vitamin C, vitamin E, potassium sorbate and water is 7:5:2:150;

[0048] (3) Tea base pretreatment: put the tea base in steam at 65°C for 50 seconds, take it out and dry it at 65°C until the water content is 4.3%, and cool the dried tea base to 28°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com