Rotary auxiliary powder mixing tank

A technology of mixing tank and powder, applied in mixers, mixers, dissolving and other directions with rotating containers, can solve the problems of material flying, powder flying, powder loss, etc., to achieve strong adaptability, reduce pollution, powder The effect of low material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

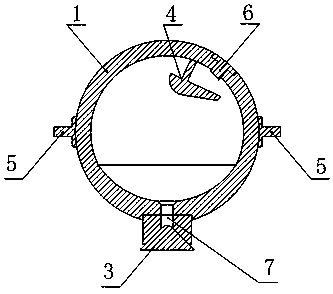

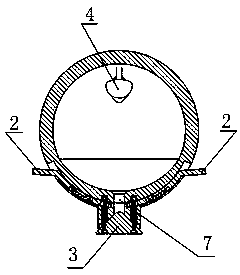

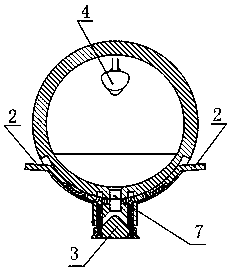

[0018] Specific implementation mode one: as figure 1 , 2 , shown in 4, a rotary auxiliary mixing tank, including a tank body 1, opening and closing device 2, conical plug 3, slow down table 4 and rotating shaft 5, the tank body 1 can hold mixed raw materials and is used for mixing A container is provided for the raw materials, and the mixed powdery raw materials are poured through the inlet 6. In order to prevent the powder from flying when pouring in, the falling speed of the powder is slowed down through the slow-down platform at the inlet 6 to prevent flying. The device controls the rotating shaft 5 on the tank body 1 to rotate and mix the materials. After the mixing is completed, pull the wrench of the opening and closing device 2, and the locking mechanism of the conical plug 3 is opened, and the locking mechanism is opened under the action of the spring. , the cone plug 3 pops open, such as image 3 As shown in , 5, the mixed raw material falls from the discharge port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com