Gravure printing machine air circulation system

A technology of air circulation system and gravure printing machine, applied in the direction of printing machine, printing, general parts of printing machinery, etc., can solve the problems of high investment cost and affecting equipment operation cost, reduce solvent residue, avoid dry surface curing, Easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

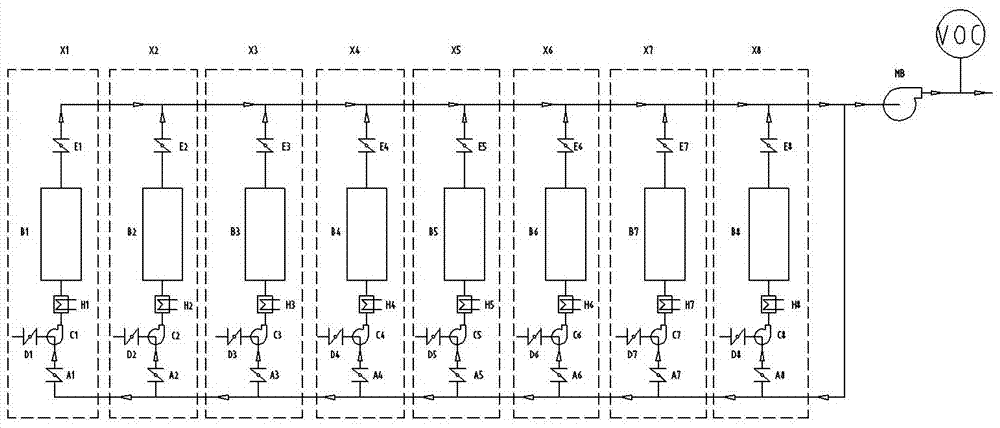

[0025] Embodiment 1: if figure 1 As shown, the air circulation system of the gravure printing machine includes several groups of printing color groups X n (n=1, 2, 3...), exhaust fan MB, and VOCs concentration detector. This embodiment adopts 8 groups of printing color groups;

[0026] Each printing color group includes the return air regulating valve An (n=1, 2, 3...), the color group air supply fan Cn (n=1, 2, 3... ...), fresh air make-up valve Dn (n=1, 2, 3...), exhaust air regulating valve En (n=1, 2, 3.... ..), and printing drying tunnel Bn (n=1, 2, 3...), air heating heat exchanger Hn (n=1, 2,...);

[0027] Taking the X1 printing color group as an example, it includes the return air regulating valve A1, the color group air supply fan C1, the fresh air supplementary valve D1, the exhaust air regulating valve E1, the printing drying tunnel B1, and the air heating heat exchanger H1.

[0028] Each printing color group is connected in parallel, and the exhaust port of each...

Embodiment approach 2

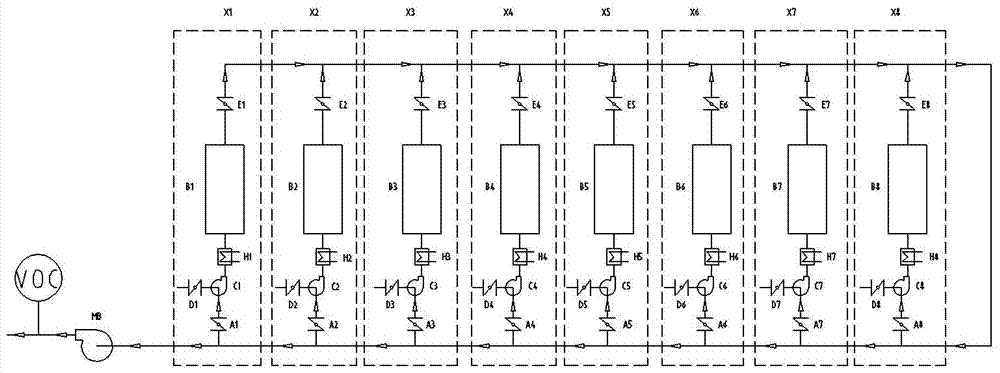

[0030] Embodiment 2: as figure 2 As shown, the air circulation system of the gravure printing machine includes several groups of printing color groups X n (n=1, 2, 3...), exhaust fan MB, and VOCs concentration detector. This embodiment is still the same Using 8 groups of printing color groups;

[0031] Each printing color group includes the return air regulating valve An (n=1, 2, 3...), the color group air supply fan Cn (n=1, 2, 3... ...), fresh air make-up valve Dn (n=1, 2, 3...), exhaust air regulating valve En (n=1, 2, 3.... ..), and printing drying tunnel Bn (n=1, 2, 3...), air heating heat exchanger Hn (n=1, 2,...);

[0032] Taking the X1 printing color group as an example, it includes the return air regulating valve A1, the color group air supply fan C1, the fresh air supplementary valve D1, the exhaust air regulating valve E1, the printing drying tunnel B1, and the air heating heat exchanger H1.

[0033] Each printing color group is connected in parallel, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com