Corrosion inhibitor microcapsules based on graphene rolls and preparation method of corrosion inhibitor microcapsules

A technology of graphene rolls and microcapsules, which is applied in the field of graphene, can solve the problems of difficulty in obtaining micronanocapsules, inability to be coated with organic drugs, and inconvenient promotion and application, and achieve the effects of mild conditions, complete structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

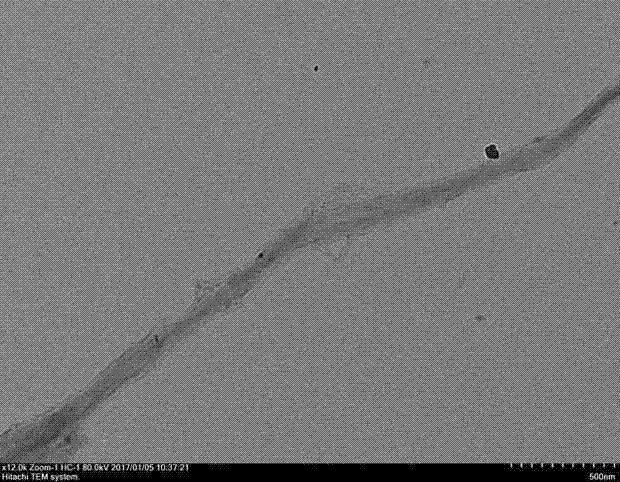

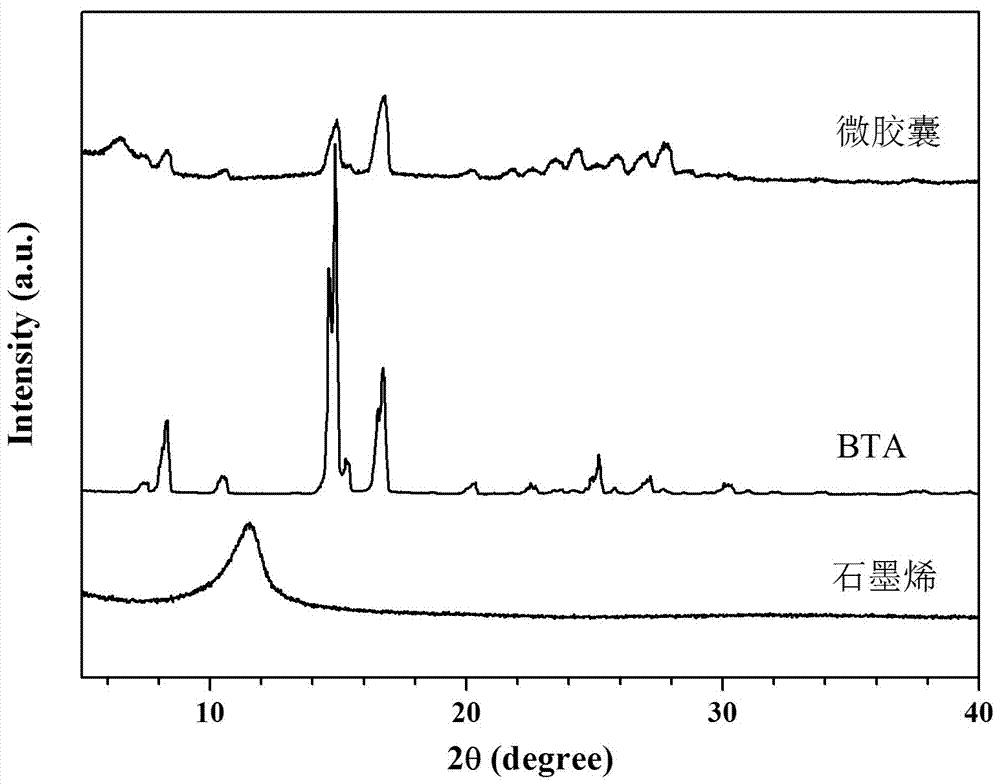

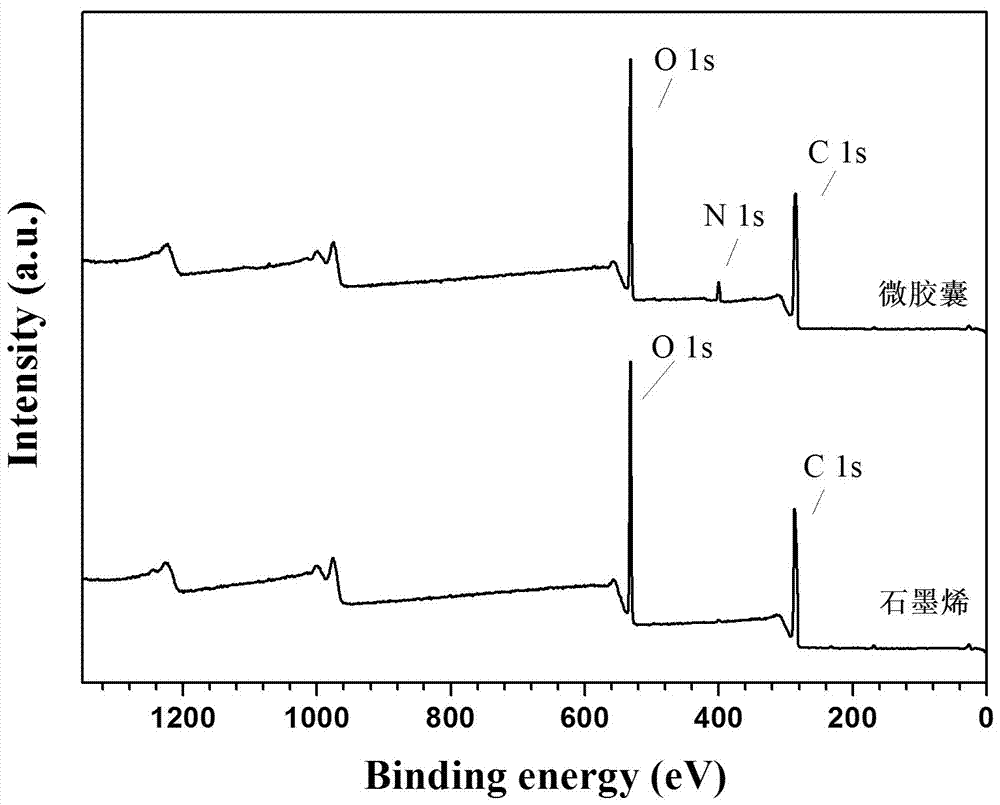

[0031] A preparation method of graphene roll microcapsules coated with benzotriazole, the method is to mix and disperse the supersaturated solution of benzotriazole solution with graphene oxide, and make the graphene into rolls by hydrothermal reaction and Coating the benzotriazole therein specifically includes the following steps:

[0032] (1) Dissolve 900 mg of benzotriazole in 45 mL of distilled water and stir for 30 minutes;

[0033] (2) Weigh 14 mg of graphene oxide, add it to the solution obtained in step (1), stir for 1 h, and then sonicate for 2 h to prepare a mixed dispersion;

[0034] (3) The mixed dispersion obtained in step (2) was transferred to a 60 mL airtight hydrothermal reaction kettle, and hydrothermally reacted at 120 °C for 8 h;

[0035] (4) After the hydrothermal reaction, cool down to room temperature naturally, centrifuge the obtained suspension at 8000 r / min for 5 min, discard the supernatant, remove the precipitate from the lower layer, and vacuum-dr...

Embodiment 2

[0041] A preparation method of graphene roll microcapsules coated with benzotriazole, the method is to mix and disperse supersaturated benzotriazole solution with graphene oxide, make graphene into rolls by hydrothermal reaction and Benzotriazole coating wherein specifically comprises the following steps:

[0042] (1) Weigh 1000 mg of benzotriazole, disperse in 45 mL of distilled water, and stir for 30 min;

[0043] (2) Weigh 14 mg of graphene oxide, add it to the solution obtained in step (1), stir for 1 hour, and then sonicate for 2 hours to prepare a mixed dispersion;

[0044] (3) Transfer the mixed dispersion obtained in step (2) to a 60 mL airtight reaction kettle, and conduct a hydrothermal reaction at 180 °C for 10 h;

[0045] (4) After the hydrothermal reaction, the hydrothermal kettle was naturally cooled to room temperature, and the obtained suspension was centrifuged at 8000 r / min for 5 minutes to separate, the supernatant was discarded, and the lower precipitate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com