CO2 mineralization and seawater resource utilization coupling method

A seawater and resource technology, applied in chemical instruments and methods, calcium/strontium/barium compounds, seawater treatment, etc., can solve problems such as low production efficiency, low enthusiasm for mineralization and emission reduction, and high processing costs, and increase process additional value, solve the CO2 emission reduction problem, and improve the effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

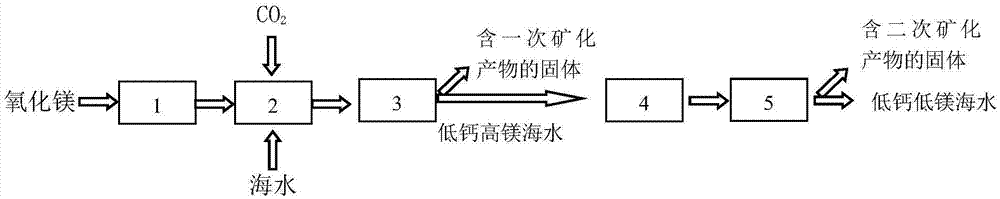

Image

Examples

Embodiment 1

[0023] Introduce 1L of seawater with a calcium ion content of 0.4g / l and a magnesium ion content of 1.28g / l into the premix tank through a pump or a high-level tank, and add magnesium oxide to the seawater. The magnesium content in magnesium oxide is the same as the calcium content in the total seawater. The molar ratio of the magnesium oxide is 1:1, fully stirred for 200min at 20°C, and the magnesium oxide and seawater are fully mixed evenly. Use a pump to make the fully mixed slurry enter the primary mineralization reactor, and the temperature in the reactor is controlled at 20°C. At the same time, carbon dioxide is charged into the reactor at a rate of 2L / h through the aeration device, and the CO 2 React with calcium ions in seawater for 60 minutes and stop the reaction. The feed liquid after a mineralization reaction is sent to the separation equipment for solid-liquid separation, the liquid phase is analyzed for calcium and magnesium ions, and the solid phase 0.38g is us...

Embodiment 2

[0026] Introduce 1L of underground brine with a calcium ion content of 0.8g / l and a magnesium ion content of 2.05g / l into the premix tank through a pump or a high-level tank, and add magnesium oxide to the seawater. The magnesium content in magnesium oxide is the same as the calcium content in the total seawater. The molar ratio of magnesia is 2:1, fully stirred at 80°C for 40 minutes, and the magnesium oxide and seawater are fully mixed evenly. Use the pump to make the fully mixed slurry enter the primary mineralization reactor, and the temperature in the reactor is controlled at 80°C. At the same time, the reactor is charged with carbon dioxide at a rate of 20L / h through the aeration device, and the CO is controlled to 2 React with calcium ions in seawater for 10 minutes and stop the reaction. The feed liquid after a mineralization reaction is sent to the separation equipment for solid-liquid separation, the liquid phase is analyzed for calcium and magnesium ions, and the s...

Embodiment 3

[0028] Introduce 1L concentrated seawater with a calcium ion content of 1.0g / l and a magnesium ion content of 3.2g / l into the premix tank through a pump or a high-level tank, and add magnesium oxide to the seawater. The magnesium content in magnesium oxide is the same as the calcium content in the total seawater. The molar ratio of magnesia is 3:1, fully stirred at 60°C for 120 minutes, and the magnesium oxide and seawater are fully mixed evenly. Use a pump to make the well-mixed slurry enter the primary mineralization reactor, and the temperature in the reactor is controlled at 60°C and stirred. At the same time, carbon dioxide is charged into the reactor at a rate of 9L / h through the aeration device, and the CO is controlled to 2 React with calcium ions in seawater for 40 minutes and stop the reaction. The feed liquid after a mineralization reaction is sent to the separation equipment for solid-liquid separation, the liquid phase is analyzed for calcium and magnesium ions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com