Rotary cylinder dryer for high-pressure airflow sludge scattering device with sprouted bed

A technology of high-pressure air flow and spouted bed, which is applied in dehydration/drying/concentrated sludge treatment, grain treatment, etc., can solve the problems of decreased drying output, low thermal efficiency of dryer, and difficulty in meeting actual needs of processing capacity, and achieves the goal of drying Increased dry output and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

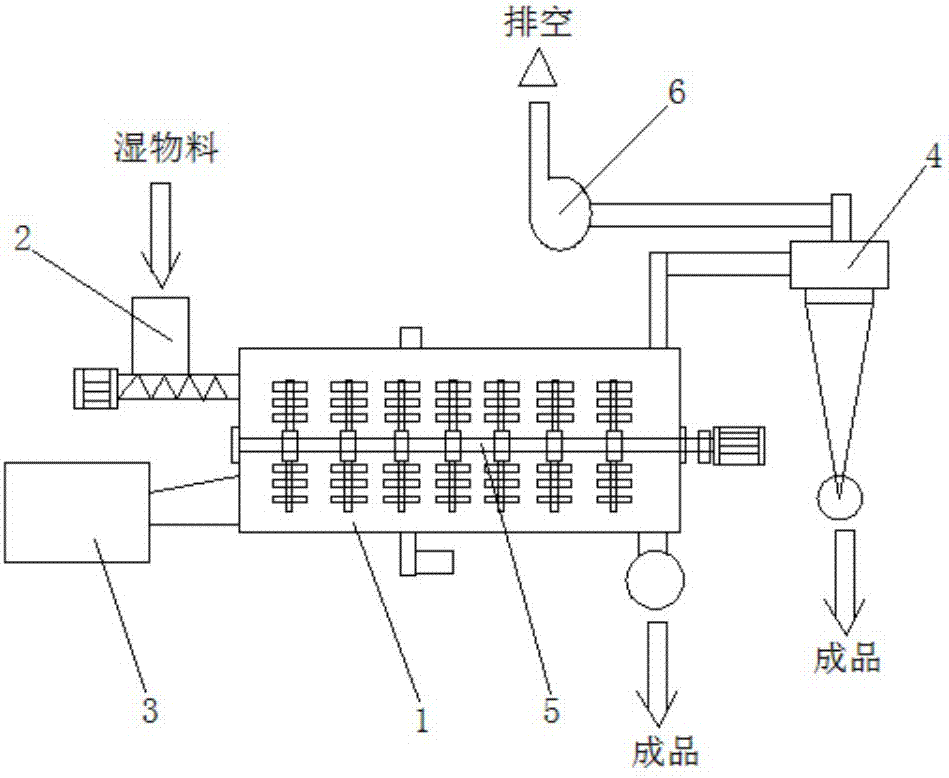

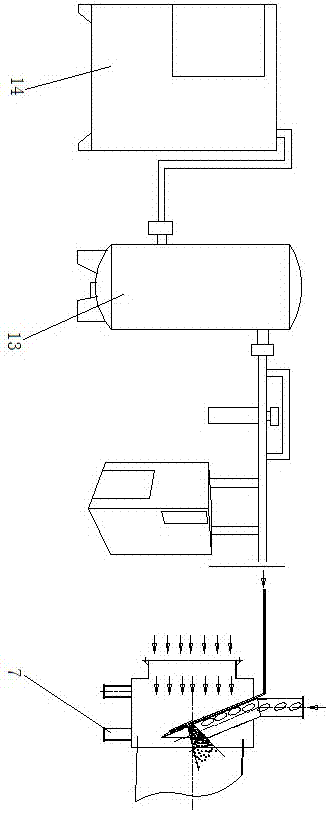

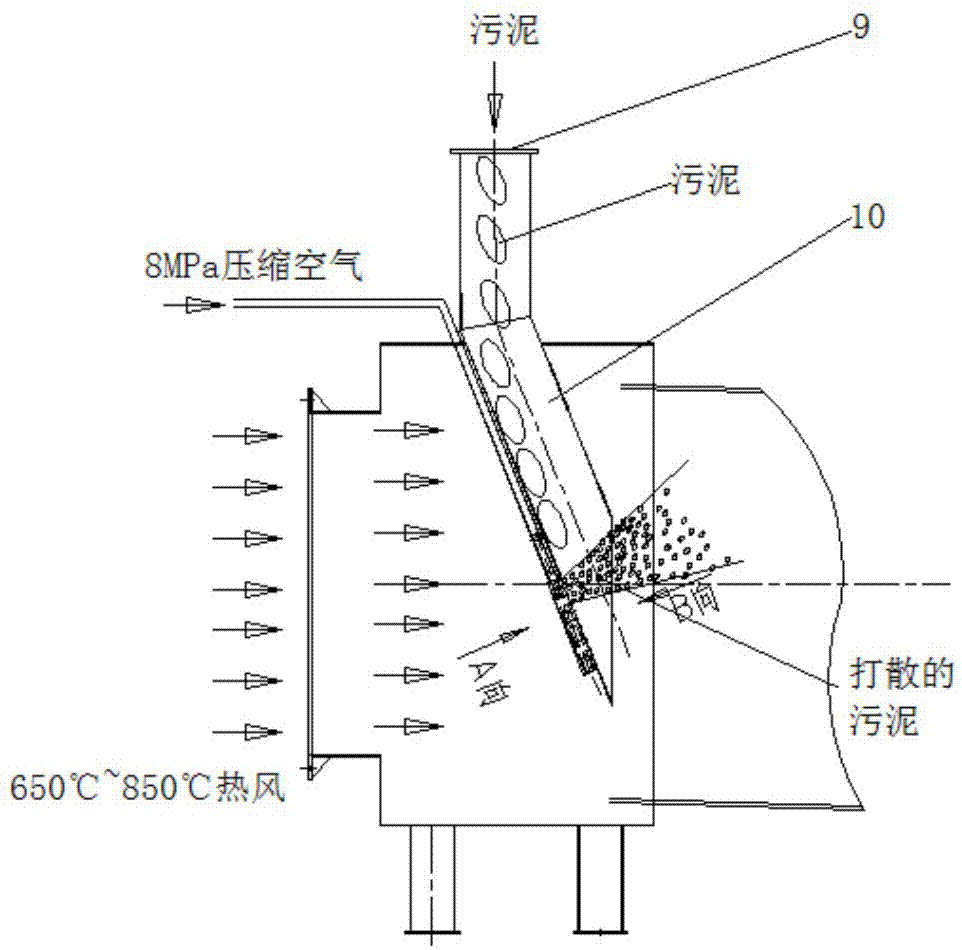

[0020] Such as Figure 2 to Figure 5 As shown, the rotary drum dryer with a spray bed high-pressure airflow sludge dispersion device of the present invention includes a dryer 7; the dryer 7 includes a rotary drum 8; the top of the rotary drum 8 is provided with sludge Inlet 9; the sludge inlet 9 extends into the rotary cylinder 8 through the sludge chute 10; the bottom of the sludge chute 10 is provided with a spouted bed; the rear side of the spouted bed is equipped with a high-pressure air chamber and a high-pressure air pipe; The high-pressure air pipe is composed of a high-pressure air main pipe 11 and a plurality of high-pressure air branch pipes 12 connected with the high-pressure air main pipe 11; the high-pressure air main pipe 11 is connected with the compressed air machine 14 through the air storage bag 13; the sprayed bed is composed of It includes first to bottom spouted beds 15, second spouted beds 16 and third spouted beds 17 in order from top to bottom; multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com