Nickel-manganese-gallium alloy with high elastic thermal effect and preparation method thereof

A nickel-manganese-gallium and thermal effect technology, applied in the field of nickel-manganese-gallium alloy and its preparation, can solve the problems of gas refrigerant environmental pollution, etc., and achieve the effect of high adiabatic temperature change, reversibility, and easy stress-induced phase change device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

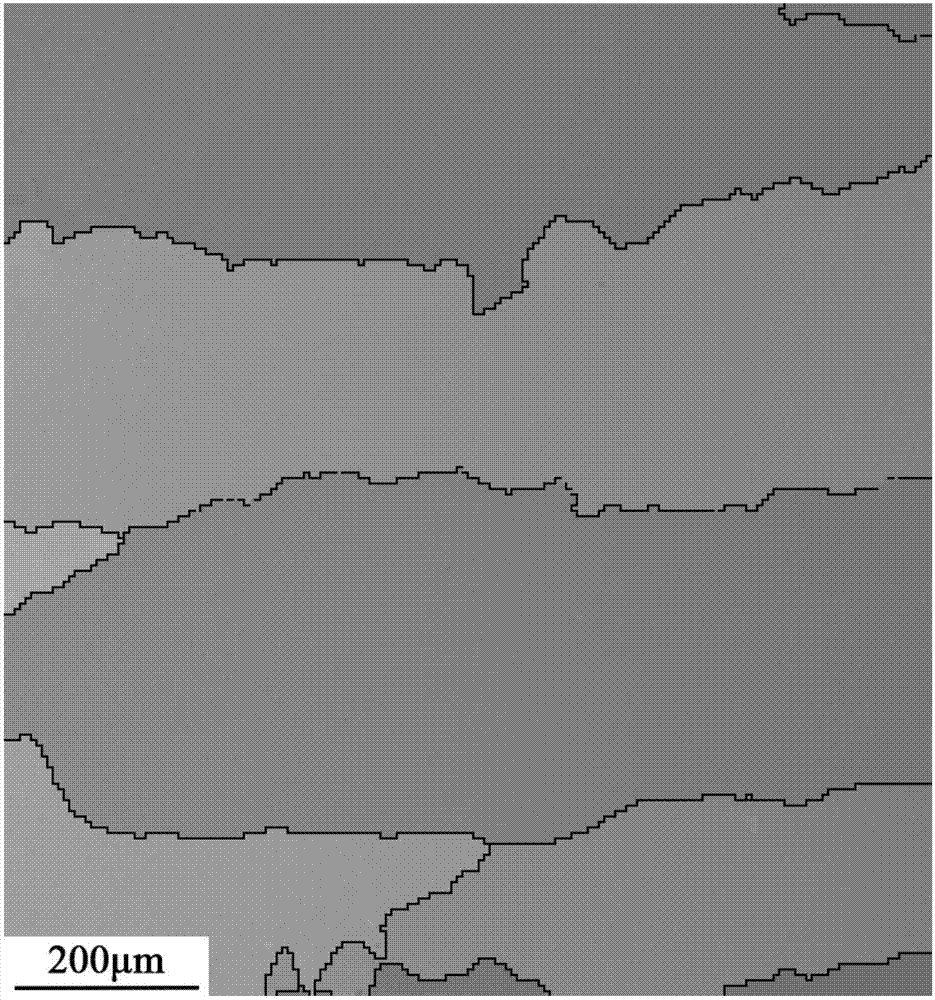

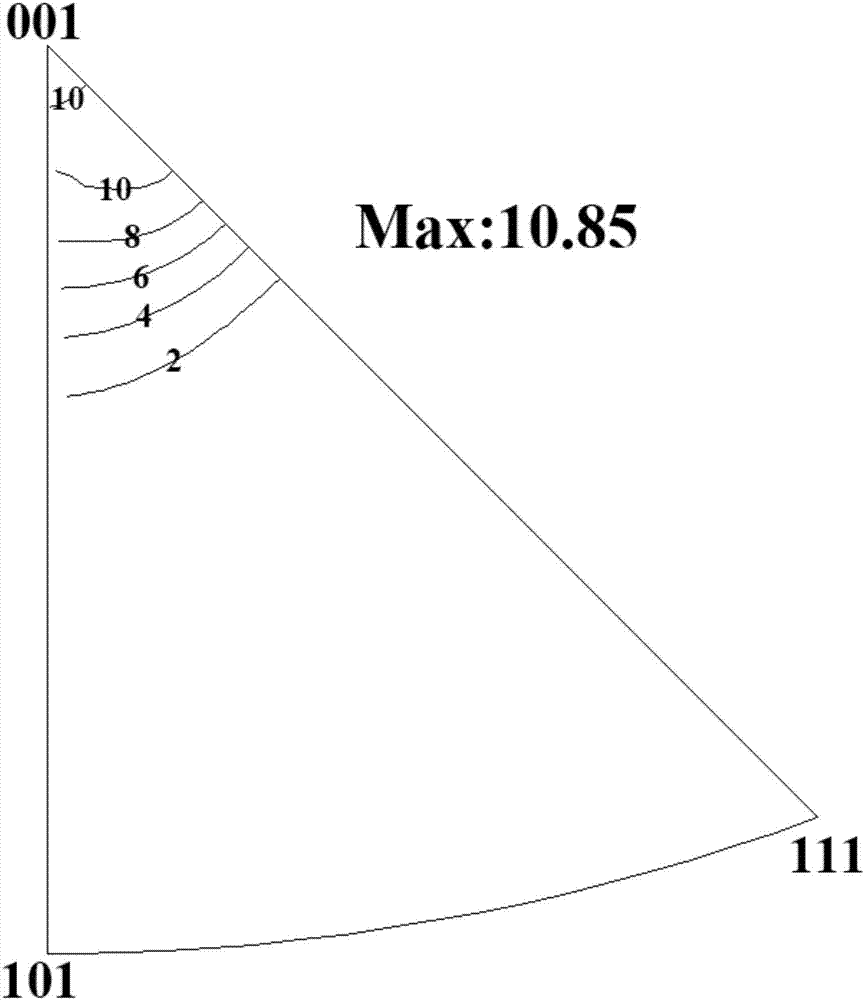

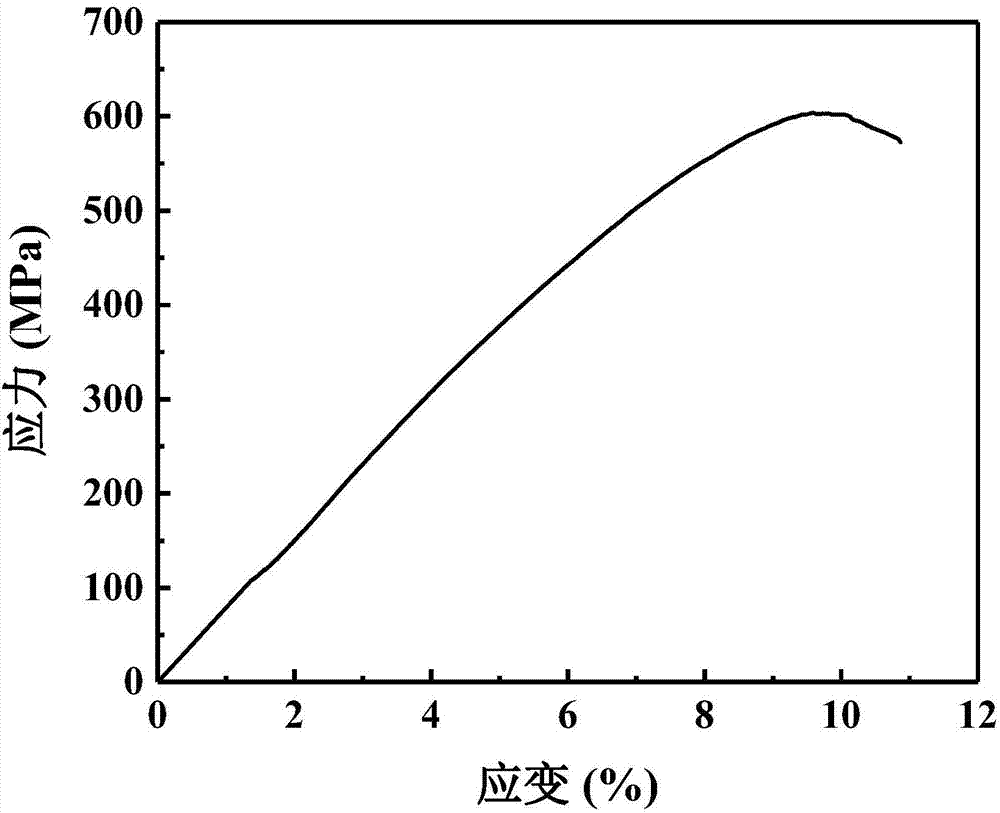

[0028] Specific implementation mode 1: a nickel-manganese-gallium alloy with high elastothermal effect described in this implementation mode is made of 48%-50% nickel, 29%-31% manganese and 21%-23% gallium; The compressive strength of nickel-manganese-gallium alloy with high elastothermal effect is greater than 600MPa, and the crystal grains are columnar crystals with orientation.

[0029] The beneficial effects of this embodiment are: this embodiment relates to a preparation method for nickel-manganese-gallium alloy to obtain high elastothermal effect, and nickel-manganese-gallium alloy is a typical ferromagnetic shape memory alloy. Using stress-induced martensitic phase transformation to generate elastothermal effect not only has high adiabatic temperature change and reversibility, but also makes it easy to prepare a stress-induced phase transition device. Therefore, using the elastothermal effect of the nickel-manganese-gallium alloy of this embodiment to prepare a refrige...

specific Embodiment approach 2

[0031] Specific embodiment two: the preparation method of a nickel-manganese-gallium alloy with high elastothermal effect described in this embodiment is completed according to the following steps:

[0032] 1. Weighing:

[0033] Weigh three pure metals of pure nickel, pure manganese and pure gallium respectively according to the atomic percentage of 48% to 50% nickel, 29% to 31% manganese and 21% to 23% gallium;

[0034] 2. Making the casting mold:

[0035] Using graphite to prepare a casting mold to obtain a graphite mold with an inner cavity length greater than 100 mm, a width greater than 50 mm, and a thickness of 15 mm to 30 mm;

[0036] 3. Vacuum induction melting method:

[0037] 1. Place the pure nickel, pure manganese and pure gallium weighed in step 1 in a vacuum induction melting furnace;

[0038] ②. First vacuumize the smelting chamber, the vacuum degree is not lower than 1Pa, and then introduce argon gas of 0.01MPa ~ 0.05MPa;

[0039] ③. Repeat step 3 ②3 to 5 t...

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step one, three pure metals of pure nickel, pure manganese and pure gallium are respectively weighed according to the atomic percentage of 48% nickel, 31% manganese and 21% gallium . Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com