Power cable joint and manufacturing method thereof

A power cable and stress cone technology, applied in the field of prefabricated power cable intermediate joints and their production, can solve the problems of inaccurate positions, inability to detect and locate cable joints, and inability to detect discharge conditions at joints, and achieve a simple joint structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

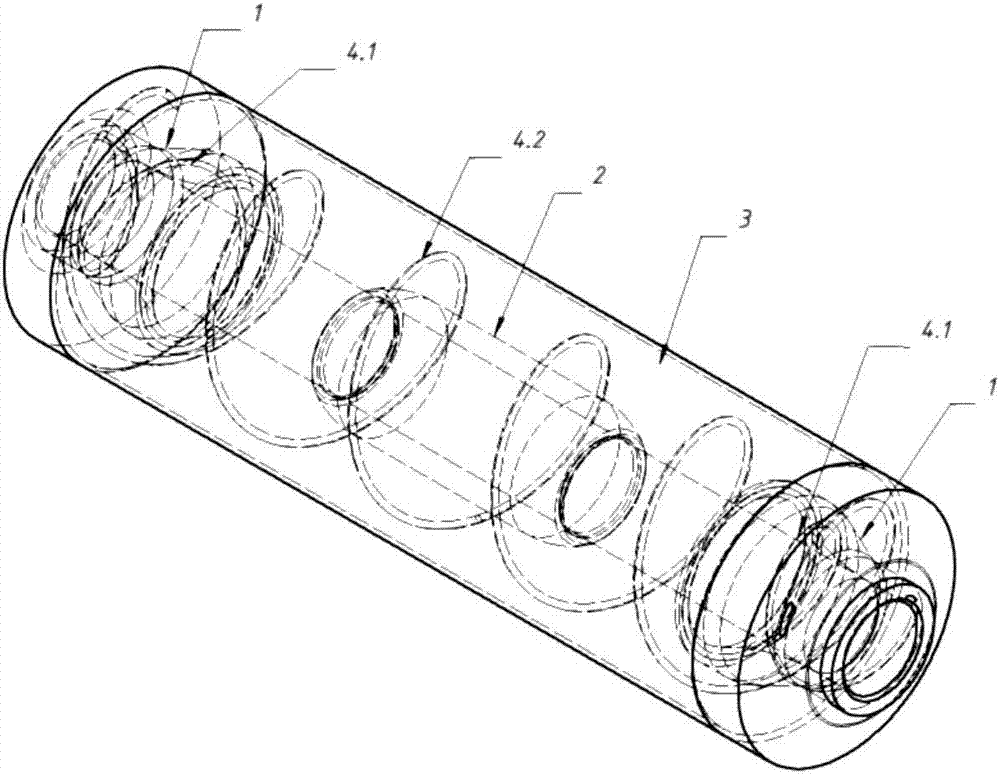

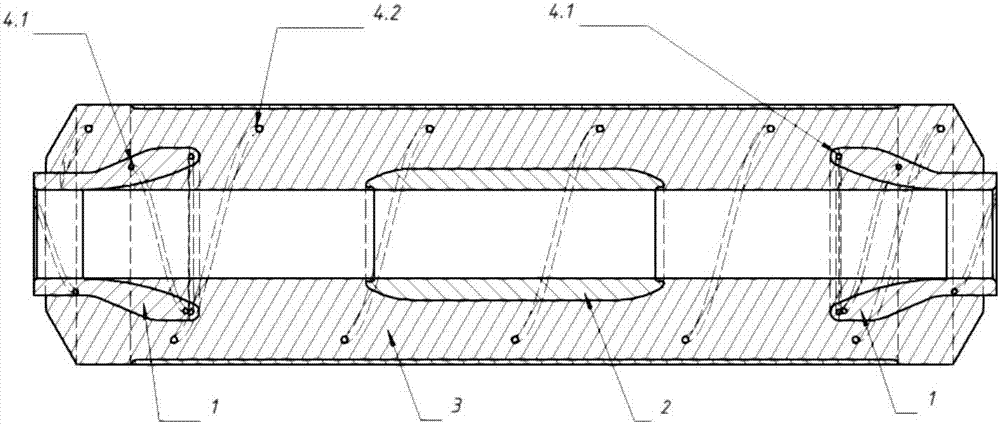

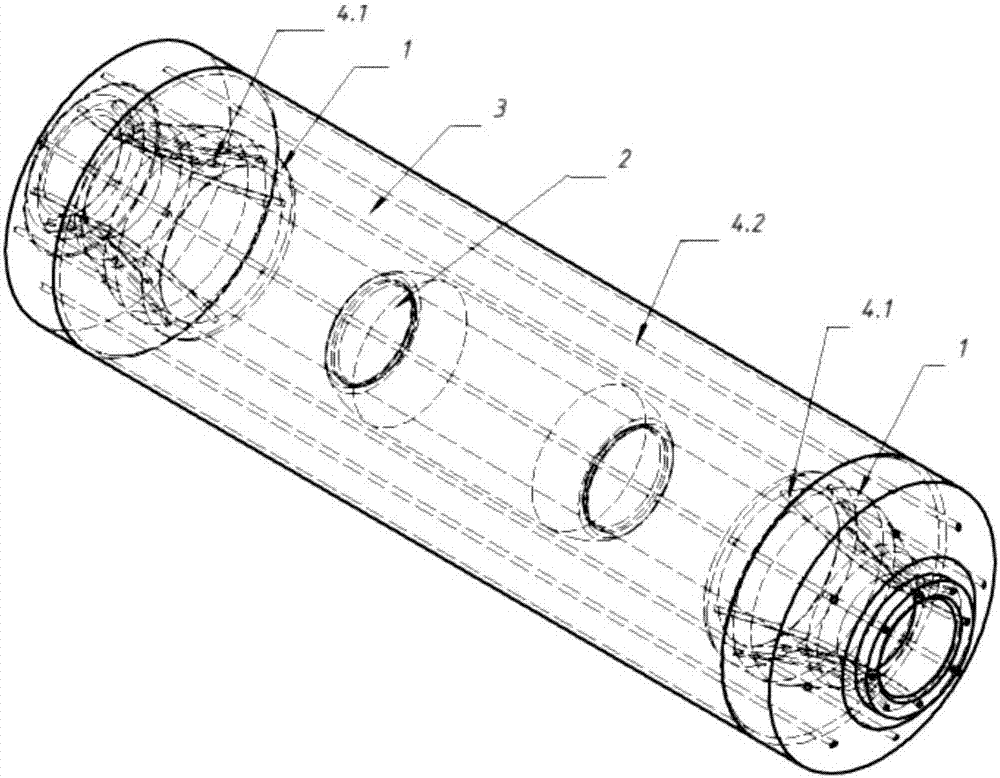

[0039] A power cable joint, comprising:

[0040] High voltage shielding tube 2;

[0041] The joint body is wrapped on the outside of the high-voltage shielding tube;

[0042] The optical fiber sensor only includes the optical fiber itself, which is located inside the joint body and runs through the entire joint body; the optical fiber sensor has a certain distance from the edge of the joint body, and the optical fiber sensor is connected to the temperature detection system and the discharge detection system.

[0043] In the present invention, the optical fiber sensor is arranged inside the joint body and runs through the entire joint body. At the same time, there is a certain distance between the optical fiber and the edge of the joint body, which simplifies the structure of the joint. The discharge phenomenon interferes with the detection of the electric field strength, so that the discharge situation at the joint body can be detected more accurately.

[0044] The joint bod...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that: the optical fiber sensor is disposed inside the connector body in a straight-through manner. Others are consistent with Example 1.

Embodiment 3

[0051] The method for making the above-mentioned power cable connector includes the following steps:

[0052] Include the following steps:

[0053] Step 1: Through electric field strength analysis and thermal analysis, determine the best fiber optic sensor implantation position inside the connector body; import this design into the mold design, and manufacture the corresponding connector body mold;

[0054] Step 2: Preset the optical fiber sensor in the mold of the joint body in a helical winding and / or straight-through manner on the workbench at the optimal implantation position of the optical fiber sensor, and then form the joint body by conventional injection molding methods;

[0055] Step 3: Sleeve the connector body on the outside of the high voltage shielding tube to form the power cable connector.

[0056] The joint body includes a stress cone 1 and an electric field enhancing insulator 3; the optical fiber sensor includes a first optical fiber 4.1 and a second optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com