Grape girdling device capable of human-assistance hand-held spring plate reducing branch clamping

A spring plate and power-assisted hand technology, applied in cutting tools, gardening tools/equipment, cutting equipment, etc., can solve the problems of small turning radius, increased flower bud ratio, small spacing, etc., and achieve small turning radius, convenient operation and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

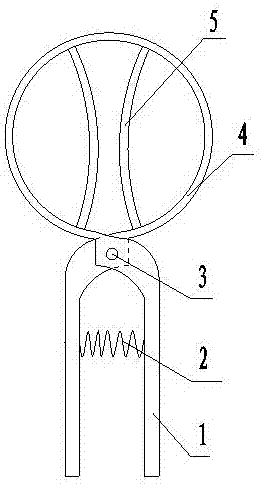

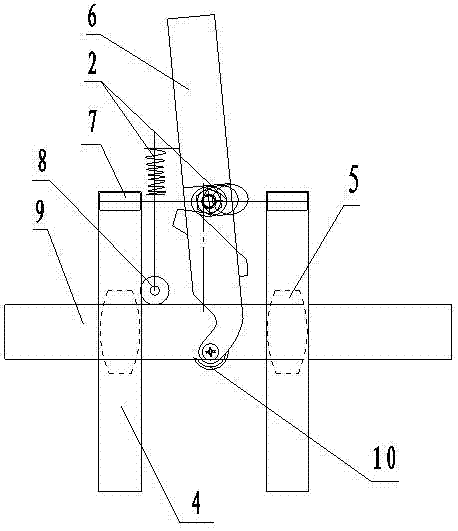

[0020] in such as Figure 1~2In the shown embodiment, a manual-assisted hand-held spring plate variable-diameter branch clamping grape girdler includes a handle 1, a spring 2, a rotating shaft 3, a spring plate 5, and a fixed circle 4, and a spring is fixedly installed on the handle 1 2. The spring 2 is a tension spring, the handle 1 is divided into two parts, the fixed circle 4 and the spring plate 5 are installed on the handle 1, the fixed circle 4 and the spring plate 5 are divided into two parts, and the two parts of the fixed circle 4 are fastened on the Together they form a full circle, the handle 1 opens and closes, and the fixed circle 4 also opens and closes accordingly. There is a groove on the fixed circle 4, and the roller 7 is embedded in the groove and rolls in the groove to make a circular motion. The connecting rod runs through the center hole of the roller 7 to connect the two grape girdling devices together, the girdling handle 6 is fixed on the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com