Processing device for breaded shrimps

A processing device and breaded shrimp technology, which is applied in food coating, baking, oil/fat baking, etc., can solve the problems of short life of the device, corrosion of the frying tank, etc., and achieve the goals of prolonging life, avoiding corrosion, and improving taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

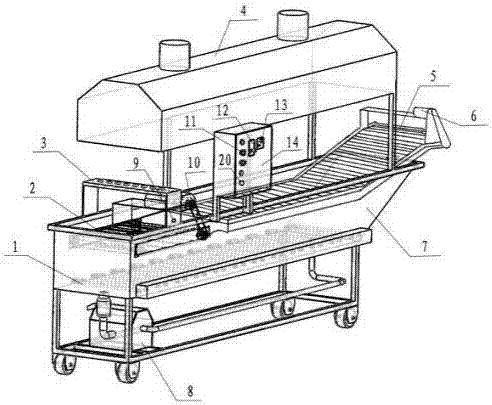

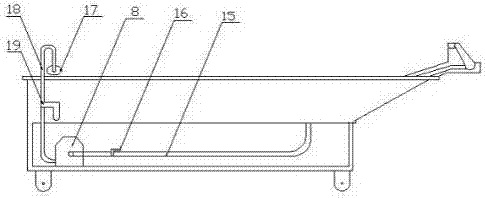

[0018] Such as Figure 1~2 Shown, a kind of processing device of breaded shrimp comprises frying tank 7, the output net belt 5 that is positioned at the top of frying tank 7 and the exhaust hood 4 that is positioned at output net belt 5 top; The bottom of frying tank 7 is provided with heating A control box 14 is provided on the outer surface of the pipe 1 and the top of the frying tank 7, and the frying tank 7 is divided into an inlet port and an outlet port. 3. An output mesh belt motor 6 is installed above the output mesh belt 5. A drive plate control stop device 9 is provided at the joint between the side of the slurry rack 3 and the drive plate 2 . It is capable of continuous operation, fast processing speed, and can automatically complete drenching, frying and oil draining; it can monitor the oil temperature in real time, and flexibly change the oil temperature according to the different temperatures required for different stages of breaded shrimp frying, so as to impro...

Embodiment 2

[0025] Such as Figure 1~2 Shown, a kind of processing device of breaded shrimp comprises frying tank 7, the output net belt 5 that is positioned at the top of frying tank 7 and the exhaust hood 4 that is positioned at output net belt 5 top; The bottom of frying tank 7 is provided with heating A control box 14 is provided on the outer surface of the pipe 1 and the top of the frying tank 7, and the frying tank 7 is divided into an inlet port and an outlet port. 3. An output mesh belt motor 6 is installed above the output mesh belt 5. A drive plate control stop device 9 is provided at the joint between the side of the slurry rack 3 and the drive plate 2, which is used to control the drive plate 2 to stop. The control box 14 is provided with a main power switch 11, an output mesh belt switch 12, a thermometer 13, a transmission board time relay, a transmission board frequency converter and a spare heating tube switch 20, and the transmission board time relay is connected with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com