Iron-nitrogen co-doped mesoporous carbon and preparation method and application thereof

A technology of co-doping and mesoporous carbon, applied in chemical instruments and methods, catalyst activation/preparation, organic chemistry, etc., can solve the problems of limited promotion and application of preparation technology, troublesome catalyst preparation process, poor selectivity of reaction, etc. Achieve the effects of increased yield, simple preparation method, and easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

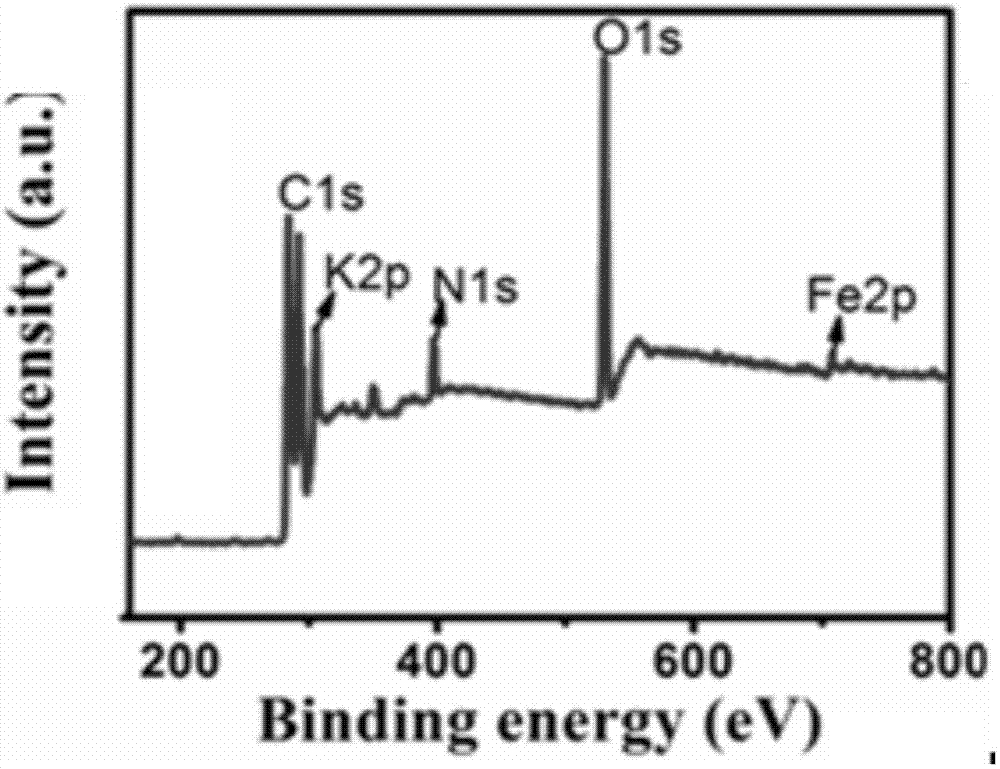

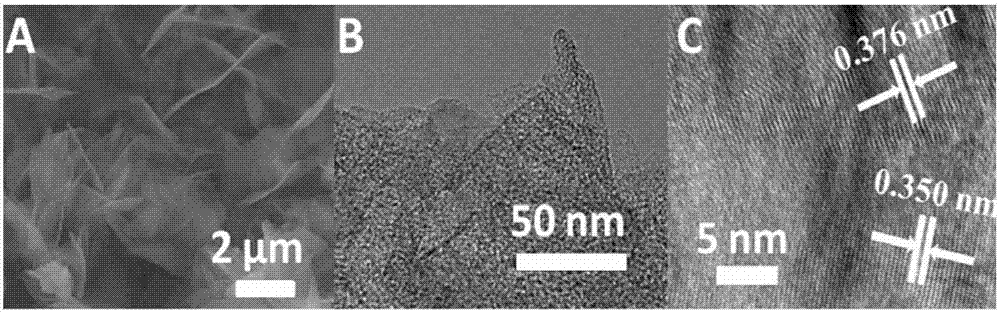

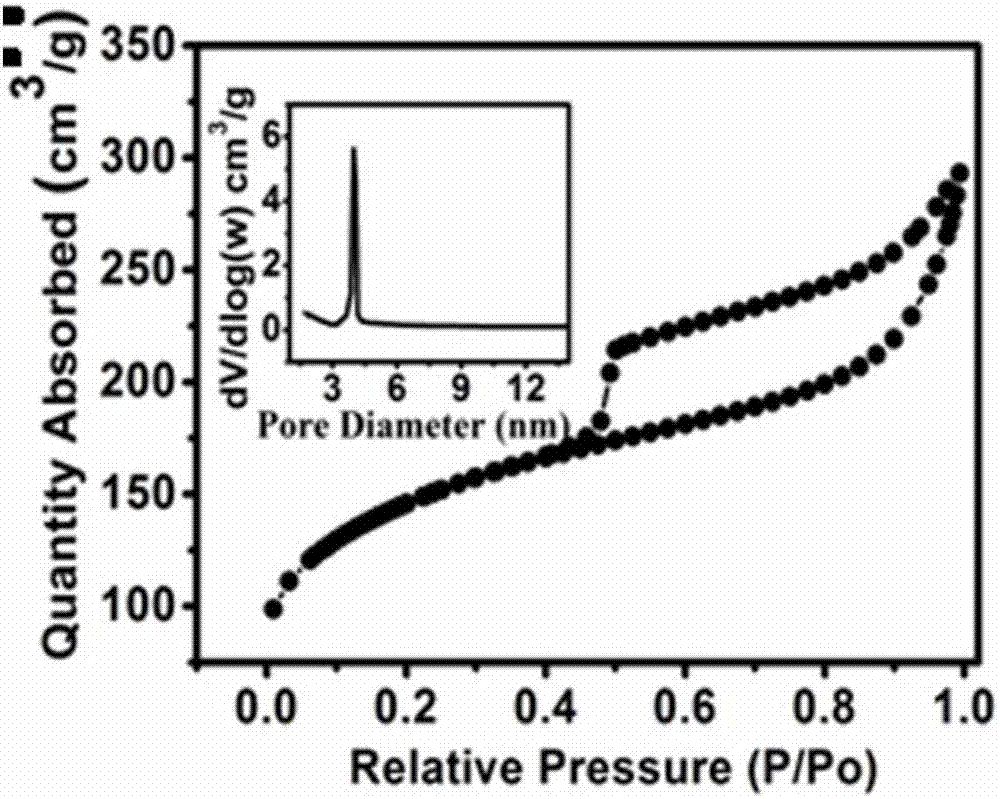

[0036] The preparation method of the iron-nitrogen co-doped mesoporous carbon is specifically: 0.02mol of citric acid monohydrate (4.3339g) and 0.01mol of magnesium nitrate hexahydrate (2.59g) are added to 10mL of deionized water, stirred and dissolved, Then put the solution into an oven at 120° C. for 24 hours until a foamy solid, namely the precursor, is obtained. Mix 4g of precursor, 4g of melamine and 4g of potassium ferrocyanide, and then burn the mixture in an atmosphere furnace at 800°C for 1 hour under the protection of nitrogen, and then cool to room temperature to obtain nitrogen and metal iron Co-doped mesoporous carbon.

Embodiment 2

[0038]The preparation method of the nitrogen-doped mesoporous carbon is specifically: 0.02mol of citric acid monohydrate (4.3339g) and 0.01mol of magnesium nitrate hexahydrate (2.59g) are added to 10mL of deionized water, stirred and dissolved, and then The solution was put into an oven at 120° C. for 24 hours until a foamy solid, namely the precursor, was obtained. 4g of the precursor and 4g of melamine were mixed together, and then the mixture was burned in an atmosphere furnace at 800° C. for 1 hour under the protection of nitrogen, and then cooled to room temperature to obtain nitrogen-doped mesoporous carbon.

Embodiment 3

[0040] The preparation method of the nitrogen-doped mesoporous carbon is specifically: 0.02mol of citric acid monohydrate (4.3339g) and 0.01mol of magnesium nitrate hexahydrate (2.59g) are added to 10mL of deionized water, stirred and dissolved, and then The solution was put into an oven at 120° C. for 24 hours until a foamy solid, namely the precursor, was obtained. Under the protection of nitrogen, 4 g of the precursor was burned in an atmosphere furnace at 800° C. for 1 hour, and then cooled to room temperature to obtain mesoporous carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com