Structure and energy conservation integrated assembly type prefabricated external wall panel and preparation method

An exterior wall panel and assembly technology, applied to walls, manufacturing tools, building components, etc., can solve the problems of external wall insulation falling off, external wall insulation secondary construction, and external wall insulation flammability, etc., to achieve more use of space , The effect of building a small wall thickness and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

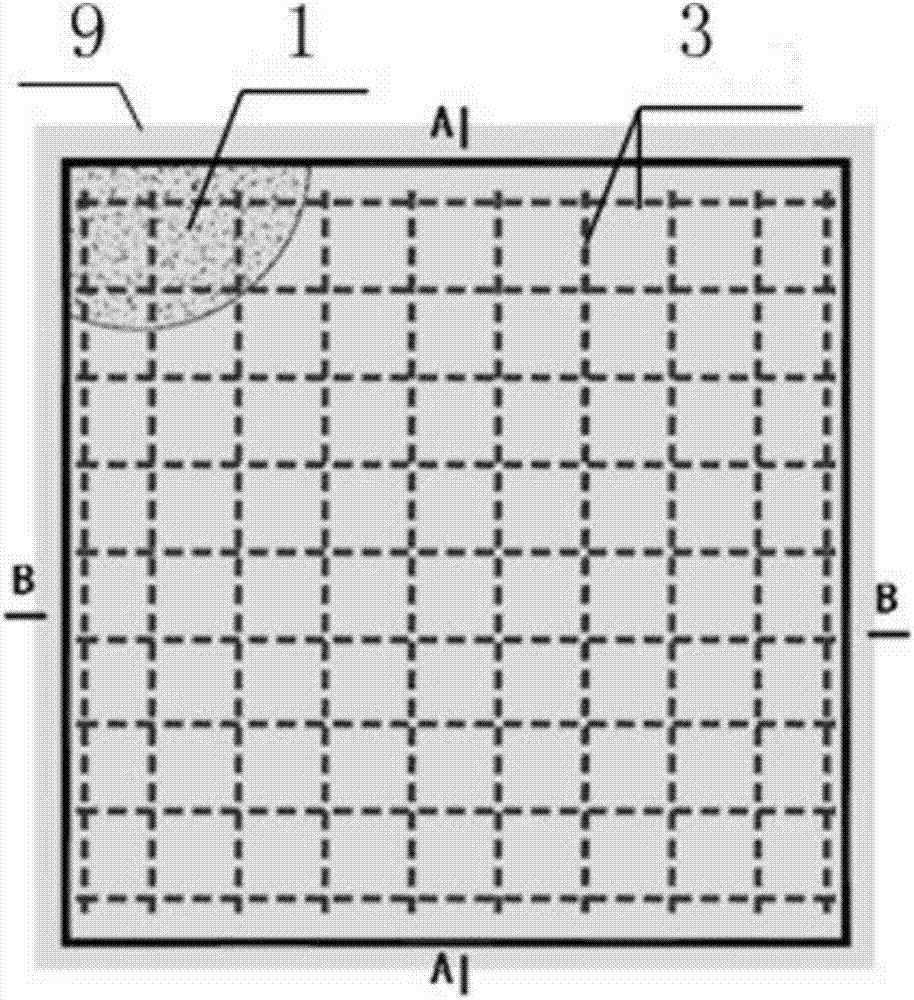

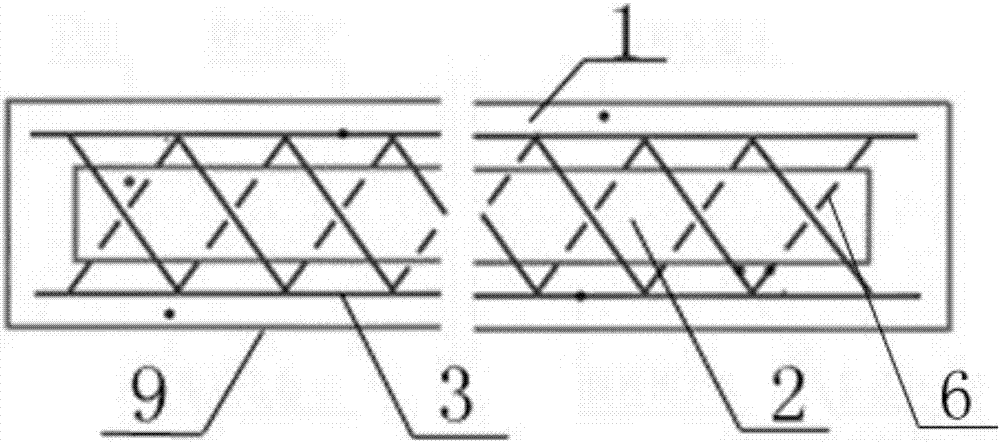

[0038] Such as Figure 1-4 As shown, an assembled prefabricated exterior wall panel with integrated structure and energy saving in the present invention includes a prefabricated exterior wall panel body 9, and the prefabricated exterior wall panel body 9 includes a lightweight aggregate concrete surface layer 1 and a rigid foamed polyurethane sandwich layer 2 and steel wire grid 3, the six outer layers of the prefabricated exterior wall panel body 9 are all light aggregate concrete surface layers 1, the steel wire grid 3 is a square frame, and the steel wire mesh is arranged in one direction (a row of diagonal The wire trusses are installed in the same direction) to form the steel wire grid 3 by welding the obliquely inserted wires. The six grid surfaces of the steel wire grid 3 are poured in the six lightweight aggregate concrete surface layers 1 correspondingly. The steel wire grid 3 can The six lightweight aggregate concrete surface layers 1 are connected into a firm overal...

Embodiment 2

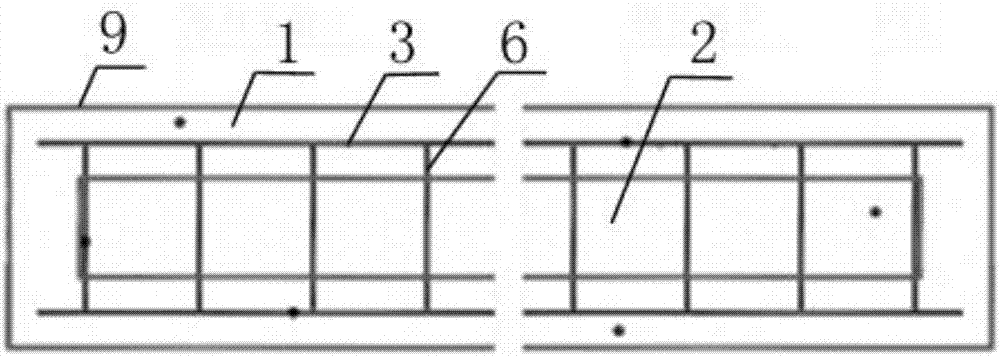

[0046] Such as Figure 4 As shown, an assembled prefabricated exterior wall panel integrating structure and energy saving. On the basis of Example 1, the steel wire mesh frame 3 is composed of an upper layer of steel wire mesh sheet 4, a lower layer of steel wire mesh sheet 5, and a unidirectionally arranged obliquely inserted wire truss 6, the obliquely inserted wire truss 6 is connected between the upper steel wire mesh sheet 4 and the lower layer steel wire mesh sheet 5. The upper steel wire mesh sheet 4 is composed of uniformly distributed longitudinal steel wires 7 and uniformly distributed horizontal steel wires) vertically interlaced; the lower layer of steel wire mesh 5 is also composed of uniformly distributed longitudinal steel wires 7 and uniformly distributed horizontal steel wires 8 .

[0047] The vertical steel wires 7 of the upper steel wire mesh 4 and the lower steel wire mesh 5 are aligned up and down, and the horizontal steel wires 8 of the upper steel wire ...

Embodiment 3

[0050] Such as Figure 5 As shown, a method for preparing an integrated prefabricated exterior wall panel with structure and energy saving, comprising steps:

[0051] Step 1) Welding the upper steel wire mesh sheet 4 and the lower layer steel wire mesh sheet 5 with the obliquely inserted wire truss 6 arranged in one direction to form a steel wire mesh frame 3;

[0052] Step 2) preparing a wall panel mold according to the size of the prefabricated exterior wall panel body 9;

[0053] Step 3) smear release agent in mould;

[0054] Step 4) pouring the lower layer of lightweight aggregate concrete into the mould, and vibrating;

[0055] Step 5) place the steel wire grid frame 3, and the grid frame is positioned;

[0056] Step 6) Uniformly spraying rigid foamed polyurethane PU; PU is foamed, and rigidly molded into a rigid foamed polyurethane sandwich layer 2;

[0057] Step 7) pouring the upper layer of lightweight aggregate concrete, vibrating and scraping;

[0058] Step 8) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com