Obstructive piston type particle damper

A particle damper and particle damping technology, applied in shock absorbers, shock absorbers, friction shock absorbers, etc., can solve the problems of small contact area between piston rod and particles, difficult to control the size of damping, affecting engineering applications, etc. To achieve the effect of simple and reliable structure, low cost and stable vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

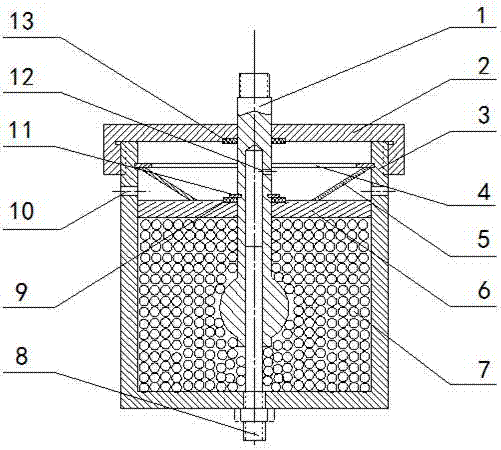

[0026] An obstructive piston type particle damper. The obstructive piston type particle damper such as figure 1 As shown, it includes a damper housing 3 , a granular damping material 7 , a cover plate 6 , a belleville spring 5 , a piston rod 1 , a guide rod 8 and a damper cover 2 .

[0027] like figure 1 As shown, the damper housing 3 is a hollow cylinder with one end closed, a screw hole is provided at the center of the closed end, and an external thread is provided at the open end of the hollow cylinder, and the housing next to the external thread is Two first ventilation holes 10 are provided. An inner annular groove is provided close to the inner wall of the port, and the distance between the inner annular groove and the bottom of the damper housing 3 is 90-93% of the height of the damper housing 3 .

[0028] like figure 1 As shown, the port of the damper housing 3 is fixedly connected with the damper cover 2 through threads, and an inner snap ring 4 is installed in th...

Embodiment 2

[0036] An obstructive piston type particle damper. Except following, all the other are with embodiment 1:

[0037] The distance between the inner annular groove and the bottom of the damper housing 3 is 92% to 94% of the height of the damper housing 3; the distance between the cover plate 6 and the bottom of the damper housing 3 is 73% of the height of the damper housing 3 ~78%; the distance between the lower end of the piston rod 1 and the bottom of the damper housing 3 is 23-28% of the height of the damper housing 3; the hole depth of the circular hole is 73-78% of the length of the piston rod 1 ; The diameter of the sphere is 1-4mm.

[0038] The particle damping material 7 is made of lead.

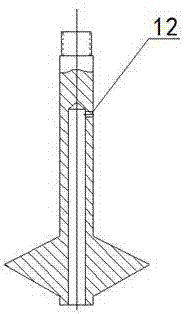

[0039] like figure 2 As shown, the body of revolution is rhombohedral.

Embodiment 3

[0041] An obstructive piston type particle damper. Except following, all the other are with embodiment 1:

[0042] The distance between the inner annular groove and the bottom of the damper housing 3 is 93-95% of the height of the damper housing 3; the distance between the cover plate 6 and the bottom of the damper housing 3 is 75% of the height of the damper housing 3 ~80%; the distance between the lower end of the piston rod 1 and the bottom of the damper housing 3 is 25-30% of the height of the damper housing 3; the hole depth of the circular hole is 75-80% of the length of the piston rod 1 ; The diameter of the sphere is 2-5mm.

[0043] The granular damping material 7 is made of copper or aluminum.

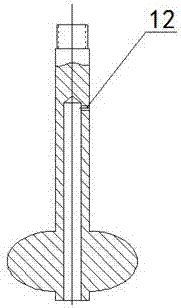

[0044] like image 3 As shown, the body of revolution is an ellipsoid.

[0045] Compared with the existing technical solutions, this specific embodiment has the following positive effects:

[0046] In this specific embodiment, the particle damping material 7 fills the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com