A Novel Microflow Gas Mass Flow Controller

A gas mass flow and micro-flow technology, applied in flow control without auxiliary power, etc., can solve problems such as difficult processing, hidden danger of slag falling, complex process, etc., and achieve compact structure layout, strong anti-pollution ability, and simple processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

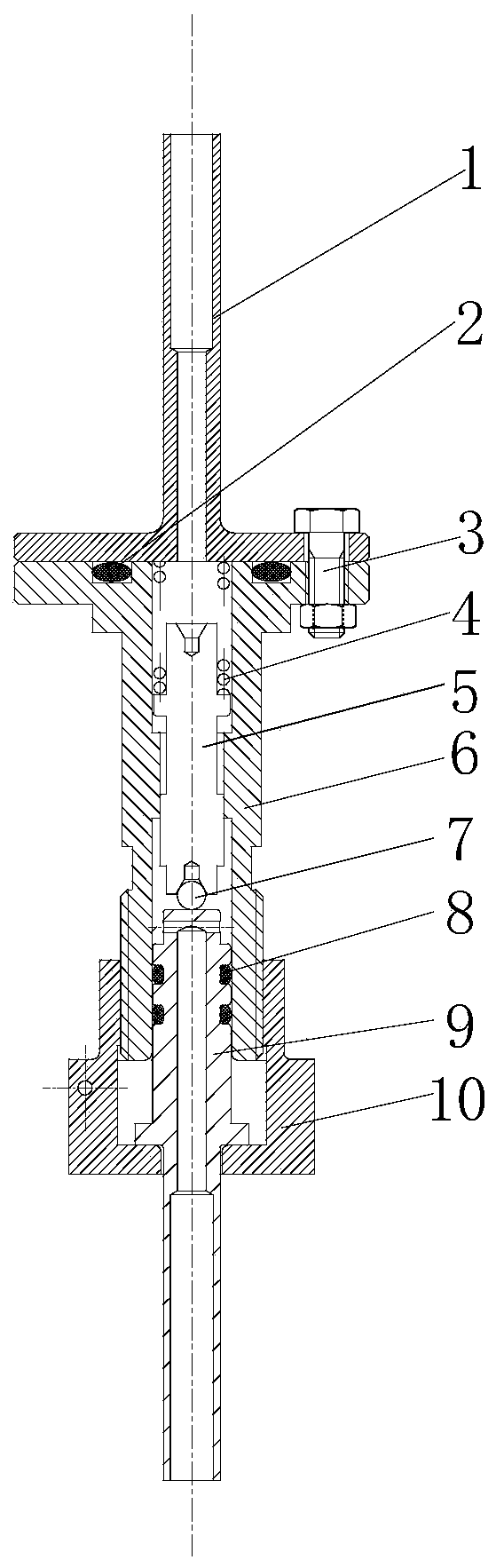

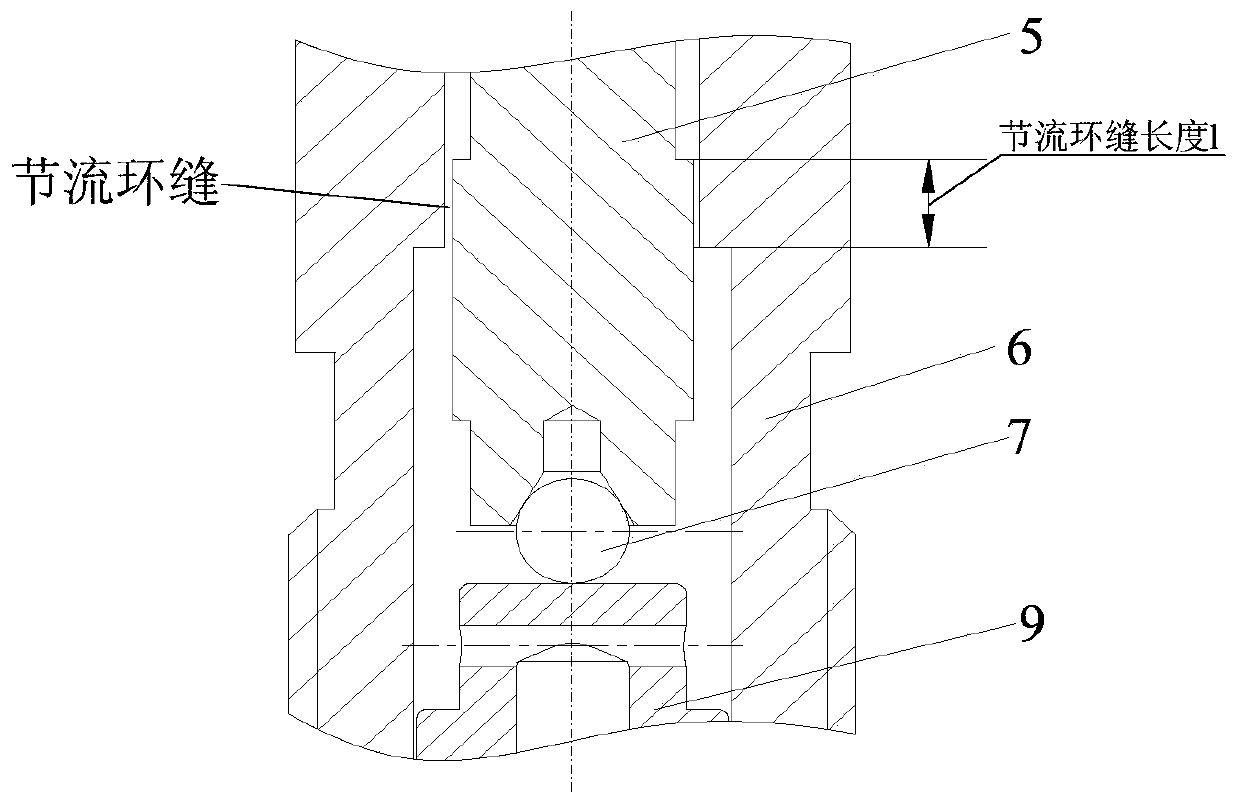

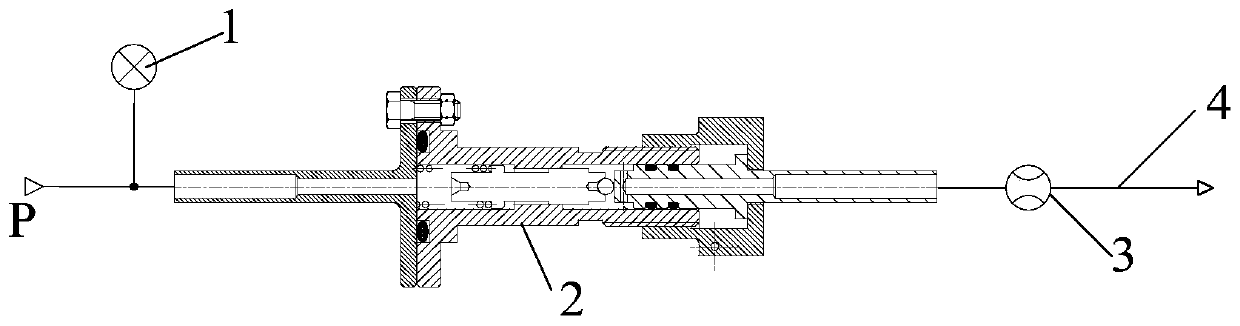

[0026] The basic idea of the present invention is to propose a novel micro-flow gas mass flow controller structure, including an inlet cover, a sealing ring 1, a fastener, a spring, a valve core, a sleeve, a steel ball, a sealing ring 2, a push rod and fasten the screw nut. The 4μm-10μm radial gap formed between the sleeve and the valve core constitutes a throttling annular seam, and when the gaseous working medium enters the controller from the air inlet, the micro-flow control is realized through the throttling annular seam. The adjustment device composed of ejector rod, steel ball, lock nut, spring, etc. can adjust the position of the valve core to achieve the purpose of controlling the length of the annular seam, and realize the precise output of a small flow rate of 20μg / s~2mg / s under a specific pressure. Compared with the conventional flow controller, the present invention adopts the valve core and the valve sleeve as hole axis fit, realizes throttling control through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com