Lithium battery

A lithium battery and lithium salt technology, which is applied to lithium batteries, secondary batteries, battery pack components, etc., can solve the problems of flammable diaphragm, melting, low flash point of organic solvents, etc., to improve safety and improve charging and discharging. performance, to solve the effect of poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

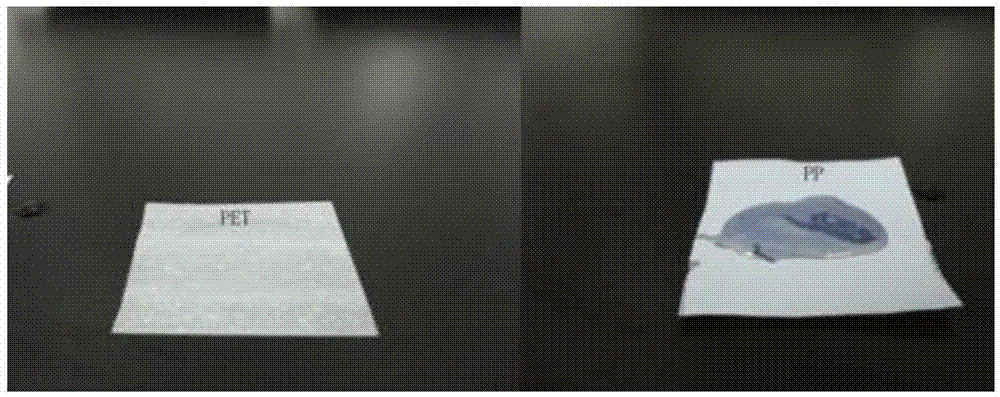

[0026] Example 1: According to the same method as Comparative Example 1, an appropriate amount of ionic liquid solvent was added dropwise on the (polyethylene terephthalate / PET) fiber separator, and the wetting performance between the two was observed with the naked eye.

Embodiment 2

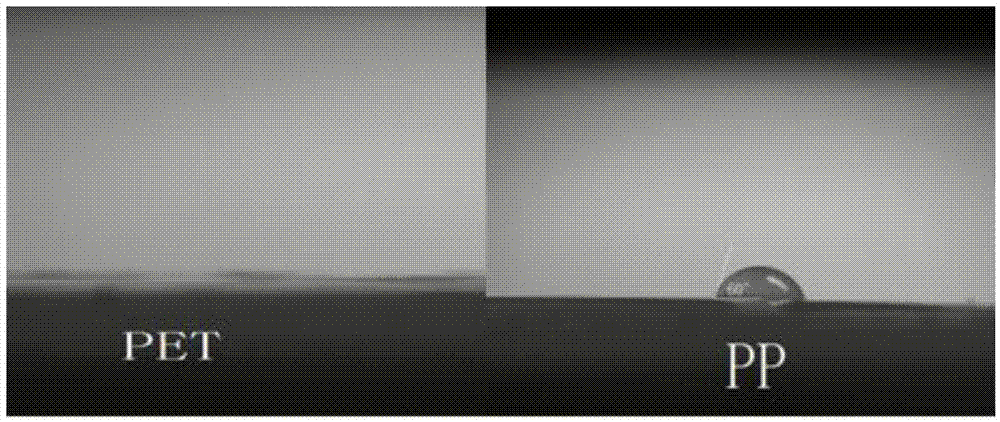

[0027] Example 2: According to the same method as Comparative Example 2, drop 5 μL of the electrolyte solution containing the ionic liquid solvent on the surface of the PET separator, obtain its image information through a contact angle measuring instrument, and then analyze the obtained image by a computer. Get the specific value of the contact angle.

Embodiment 3

[0028] Embodiment 3: according to the same method as Comparative Example 3, the difference is that the PET diaphragm is soaked in ionic liquid (PYR 13 In TFSI), the flammability of the diaphragm was observed by direct ignition with an ignition gun.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com