A kind of preparation method of electrode composite material

A composite material and electrode technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems affecting the volume energy density and power energy density of lithium-sulfur batteries, the low-temperature performance and dynamic characteristics are not ideal, and the capacity density of sulfur-based cathode materials is affected and other problems, to achieve the effect of improving cycle performance and conductivity, improving conductivity and cycle performance, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

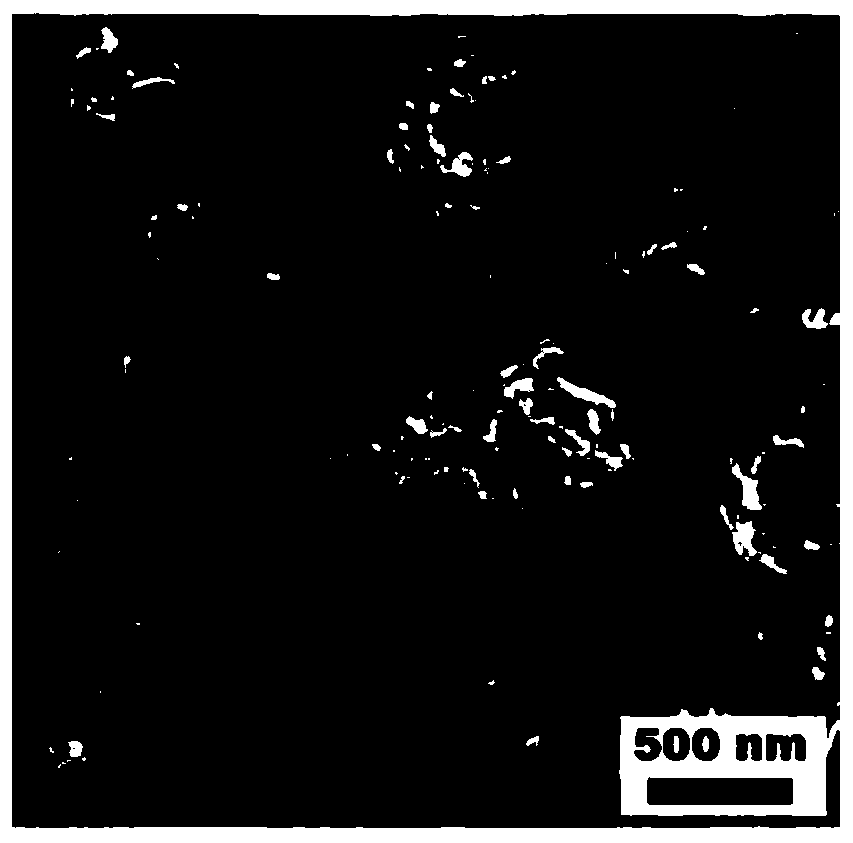

Image

Examples

Embodiment 1

[0025] (1) Dissolve 10g of polyacrylonitrile fibers in 100mL of dimethylformamide solution, heat and stir at 80°C for 2 hours, and stop heating after stirring;

[0026] (2) Add 2g of sucrose to the above solution, stir for 30min, and make it fully mixed;

[0027] (3) Add 40g of sulfur powder into the solution (in order to mix the sulfur powder evenly in the solution, add 40g of sulfur powder to the solution in 8 times and stir for 10min each time) when the sulfur powder is completely put in, stir for 1.5h again to make the sulfur The powder and the solution are thoroughly mixed;

[0028] (4) Put the mixture into a drying oven at 80° C. for drying for 15 hours to obtain a carbon-coated vulcanized polyacrylonitrile precursor;

[0029] (5) The carbon-coated vulcanized polyacrylonitrile precursor was ball-milled for 3 hours at a rate of 350r / min to obtain its powder;

[0030] (6) Put the above-mentioned carbon-coated vulcanized polyacrylonitrile precursor powder into a tube furn...

Embodiment 2

[0035] The steps are the same as in Example 1, except that the tube furnace in step (6) is heated to 450°C.

[0036] (1) Dissolve 10g of polyacrylonitrile in 100mL of dimethylformamide solution, heat and stir at 80°C for 2 hours, and stop heating after stirring;

[0037] (2) Add 2g of sucrose to the above solution, stir for 30min, and make it fully mixed;

[0038] (3) Add 40g of sulfur powder into the solution (in order to mix the sulfur powder evenly in the solution, add 40g of sulfur powder to the solution in 8 times and stir for 10min each time) when the sulfur powder is completely put in, stir for 1.5h again to make the sulfur The powder and the solution are thoroughly mixed;

[0039] (4) Put the mixture into a drying oven at 80° C. for drying for 15 hours to obtain a carbon-coated vulcanized polyacrylonitrile precursor;

[0040] (5) The carbon-coated vulcanized polyacrylonitrile precursor material was ball milled at a rate of 350r / min for 3h to obtain its powder;

[00...

Embodiment 3

[0045] The steps are the same as those in Example 1, except that the tube furnace in step (6) is heated to 350°C.

[0046] (1) Dissolve 10g of polyacrylonitrile in 100mL of dimethylformamide solution, heat and stir at 80°C for 2 hours, and stop heating after stirring;

[0047] (2) Add 2g of sucrose to the above solution, stir for 30min, and make it fully mixed;

[0048] (3) Add 40g of sulfur powder into the solution (in order to mix the sulfur powder evenly in the solution, add 40g of sulfur powder to the solution in 8 times and stir for 10min each time) when the sulfur powder is completely put in, stir for 1.5h to form a uniform phase solution;

[0049] (4) Put the mixture into a drying oven at 80° C. for drying for 15 hours to obtain a carbon-coated vulcanized polyacrylonitrile precursor;

[0050] (5) The carbon-coated vulcanized polyacrylonitrile precursor material was ball milled at a rate of 350r / min for 3h to obtain its powder;

[0051] (6) Put the above-mentioned car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com