Salt-reduced and preservative-free soybean originally brewed sauce and brewing method thereof

A technology without preservatives and soybeans, which is applied in food ingredients as taste improvers, food ingredients as taste improvers, food science, etc. It can solve the problems of salty products and poor taste, and achieve the effect of reducing salt and stabilizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

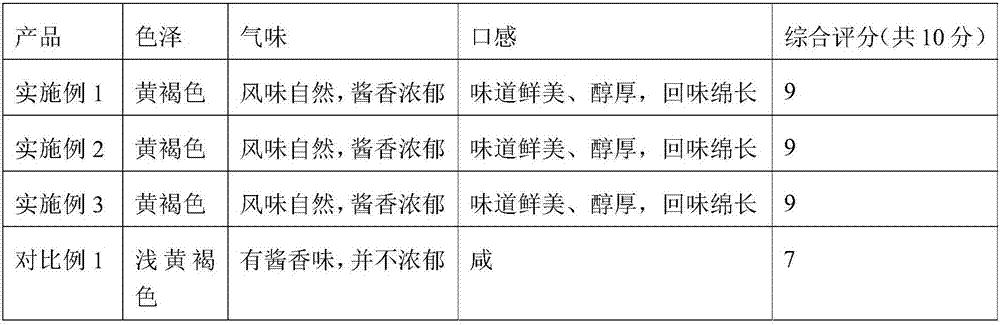

Examples

Embodiment approach

[0017] According to a typical implementation of the present invention, S3 specifically includes: mixing the culture solution with 5-8wt% brine at a weight ratio of 1:10 to obtain the mixed brine of bacteria; Mix at a ratio of 3:2, stir evenly, ferment at 23°C to 36°C, and ferment for 3 to 4 months. After the processing under these technological conditions, it will be beneficial to prolong the shelf life of the original soybean paste.

[0018] Preferably, S1 specifically includes: cooking the soybeans after cleaning, the cooking temperature is 110°C-120°C, and the time is 10 minutes; %~30%.

[0019] Preferably, the temperature and time of low-temperature koji making are controlled as follows: the temperature in the early stage is controlled at 28°C to 30°C, the temperature in the middle stage is 30°C to 36°C, the temperature in the later stage is 23°C to 30°C, and the total time for koji making is 36°C. ~40 hours.

[0020] The time of early stage, middle stage and late stage...

Embodiment 1

[0024] Soybeans are cleaned and steamed at a cooking temperature of 110-120°C for 10 minutes; wheat flour is cooked at a cooking temperature of 100°C-120°C and the cooking time is 10 minutes; the moisture content of wheat flour steamed noodles is controlled at 27%-30% After mixing, add Aspergillus oryzae for low-temperature koji making. The temperature in the early stage is controlled at 28°C to 30°C, the temperature in the middle stage is 30°C to 36°C, and the temperature in the later stage is 23°C to 30°C. 10 hours, the total time for making koji is about 38 hours; After hyperosmotic pressure-resistant lactic acid bacteria (commercially available) are activated on a slope with a hyperosmotic medium, then liquid culture is carried out to obtain a bacterial cell concentration of 10 7 CFU / mL of the culture solution, the culture solution and the saline with a mass percentage of 8wt% are mixed in a weight ratio of 1:10 to obtain a strain mixed brine, and then the strain mixed brin...

Embodiment 2

[0027] Soybeans are cleaned and steamed at a cooking temperature of 110-120°C for 10 minutes; wheat flour is cooked at a cooking temperature of 110-120°C and the cooking time is 10 minutes; the moisture content of the wheat flour steamed noodles is controlled at 27% to 30%; Then add Aspergillus oryzae for low-temperature koji making. The early temperature is controlled at 28°C-30°C, the mid-stage temperature is 30°C-36°C, and the later stage temperature is 23°C-30°C. The early, middle, and late periods are respectively 8-10 hours. , the total time for making koji is about 38 hours; the hyperosmotic pressure-resistant lactic acid bacteria (domesticated by our company, available in the market) are activated on a slope with a hyperosmotic medium, and then liquid culture is carried out to obtain a thalline concentration of 10 7 CFU / mL of the culture solution, the culture solution and the saline with a mass percentage of 5wt% are mixed in a weight ratio of 1:10 to obtain a strain mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com