Nano-hydroxyapatite/polycaprolactone gradient functional material prepared through induction of high-voltage electrical field and preparation method thereof

A technology of nano-hydroxyapatite and gradient functional materials, which is applied in medical science, tissue regeneration, prosthesis, etc., to achieve the effect of good toughness and environmental protection during processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

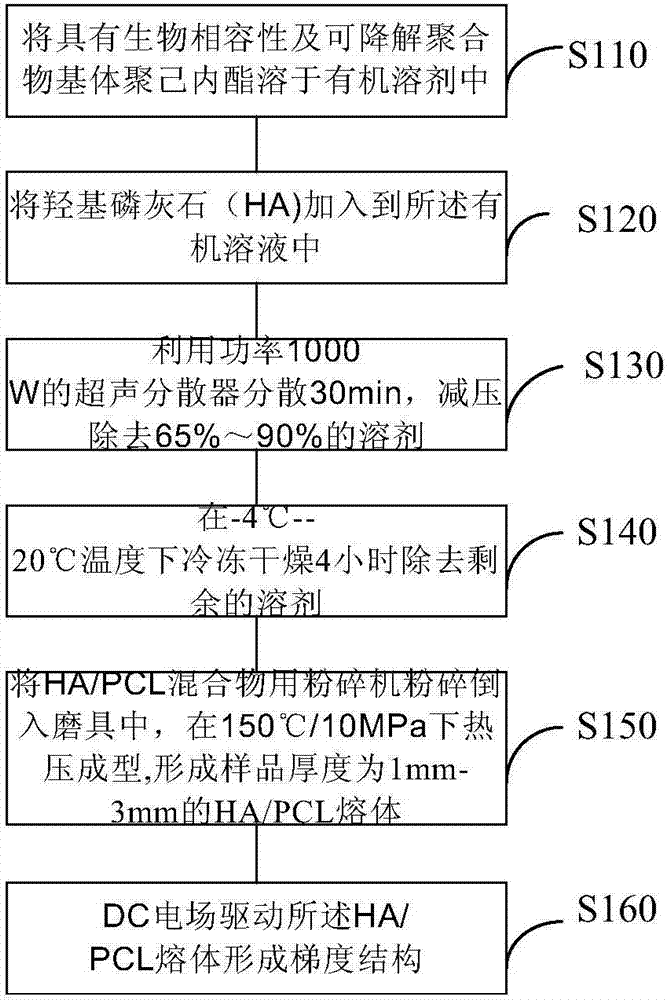

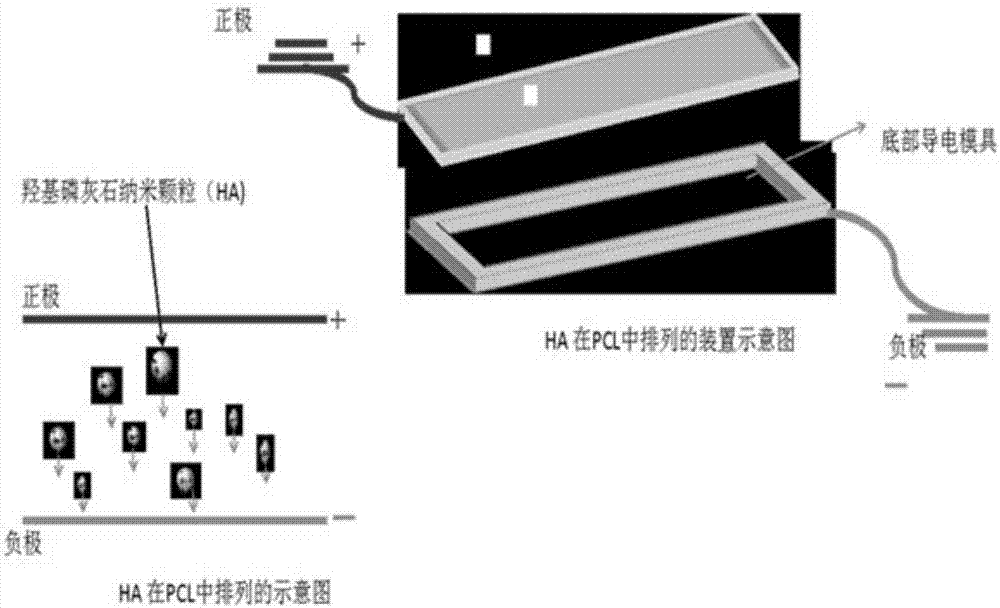

[0032] This application provides a preparation method of nano-hydroxyapatite / polycaprolactone gradient functional material induced by high-voltage electric field, figure 1 It is a flow chart of the preparation method of nano-hydroxyapatite / polycaprolactone gradient functional material induced by high-voltage electric field in the preferred embodiment of the present application, figure 2 The principle diagram of the preparation method of the nano-hydroxyapatite / polycaprolactone gradient functional material induced by high-voltage electric field for the preferred embodiment of the application; please refer to figure 1 with figure 2 , the preparation method comprises:

[0033] Step S110, dissolving polycaprolactone (PCL), a biocompatible and degradable polymer matrix, in an organic solvent;

[0034] Wherein, the organic solvent in the step S110 is one or more of toluene, tetrahydrofuran, ethyl acetate, dichloromethane, chloroform and dioxane.

[0035] Step S120, adding hydro...

Embodiment 1

[0046] S1, 10g PCL was dissolved in organic solvent 100ml toluene at 70°C;

[0047] S2, adding 0.1g HA to the solution;

[0048] S3, use an ultrasonic disperser with a power of 1000W to disperse for 30 minutes, and remove 80% of the solvent under reduced pressure at 70°C;

[0049] S4, the remaining paste is dried in a freeze drying oven at -4°C for 4 hours to remove the remaining solvent;

[0050] S5, crush the HA / PCL mixture with a pulverizer and pour it into a grinding tool, and heat press it at 150°C / 10MPa to form a sample with a thickness of 1mm.

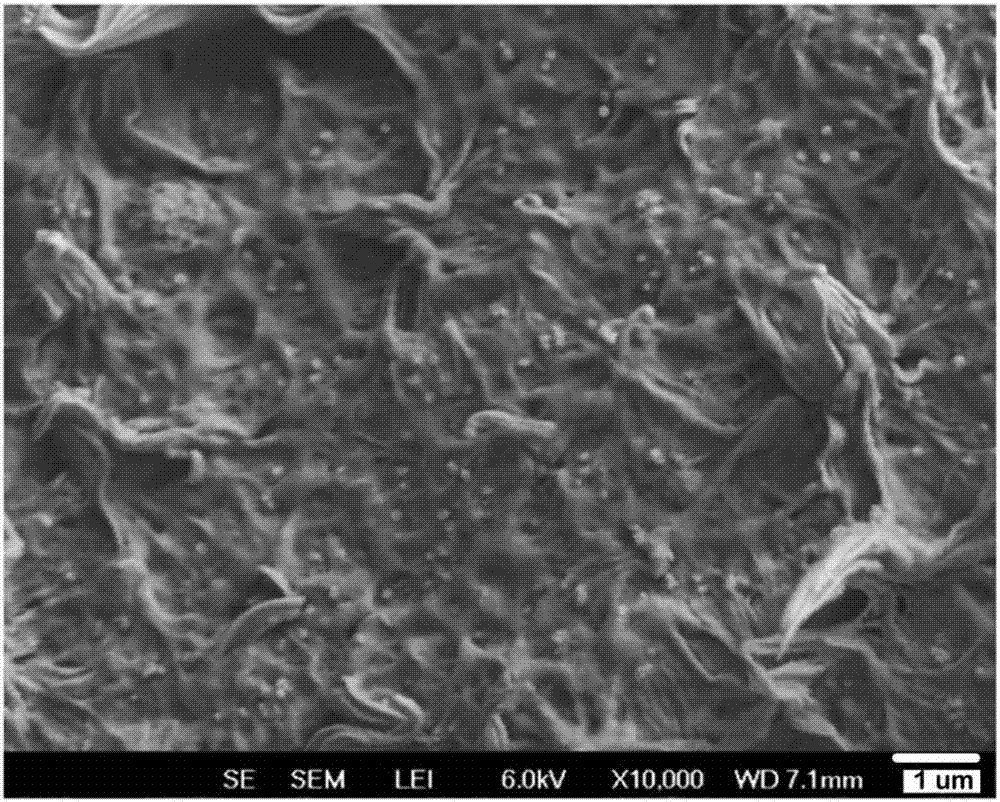

[0051] S6, the DC electric field drives the HA / PCL melt to form a gradient structure; put the hot-pressed sheet into a 1mm thick, metal conductive mold at the bottom, and put the mold on a heating table with adjustable temperature. After applying a DC voltage of 800V, the sample was maintained at 80°C for 1 hour, then the temperature was lowered to room temperature, and the electric field was removed. After cooling, the sample...

Embodiment 2

[0053] S1, 10g PCL was dissolved in 100ml dioxane at 70°C;

[0054] S2, adding 0.5g HA to the solution;

[0055] S3, use an ultrasonic disperser with a power of 1000W to disperse for 30 minutes, and remove most of them under reduced pressure at 70°C;

[0056] S4, the remaining paste is dried in a freeze drying oven at -4°C for 4 hours to remove the remaining solvent;

[0057] S5, crush the HA / PCL mixture with a pulverizer and pour it into a grinding tool, and heat press it at 150°C / 10MPa to form a sample with a thickness of 1mm.

[0058] S6, a gradient structure is formed under the drive of a DC electric field; the hot-pressed sheet is put into a mold with a thickness of 1 mm and a metal conductive sheet at the bottom, and the mold is placed on a heating table with adjustable temperature. After applying a DC voltage of 800V, the sample was maintained at 100°C for 1 hour, then the temperature was lowered to room temperature, the electric field was removed, and the sample was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com