LMD laser manufacturing process based on bionic function

A technology of manufacturing process and bionic function, which is applied in the field of LMD laser manufacturing process based on bionic function, can solve the problems of affecting the final performance of the metal coating layer and prone to brittle intermetallic compounds, so as to save raw materials, improve production efficiency and production quality , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention provides an LMD laser manufacturing process based on bionic functions. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention is further described in detail with reference to the accompanying drawings and examples. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

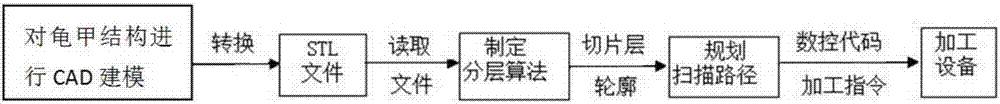

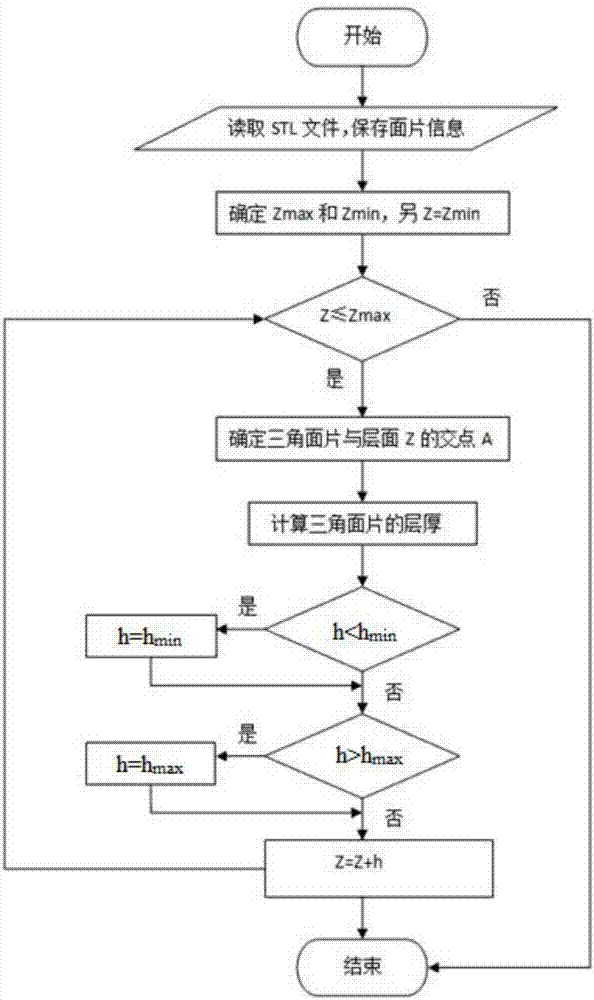

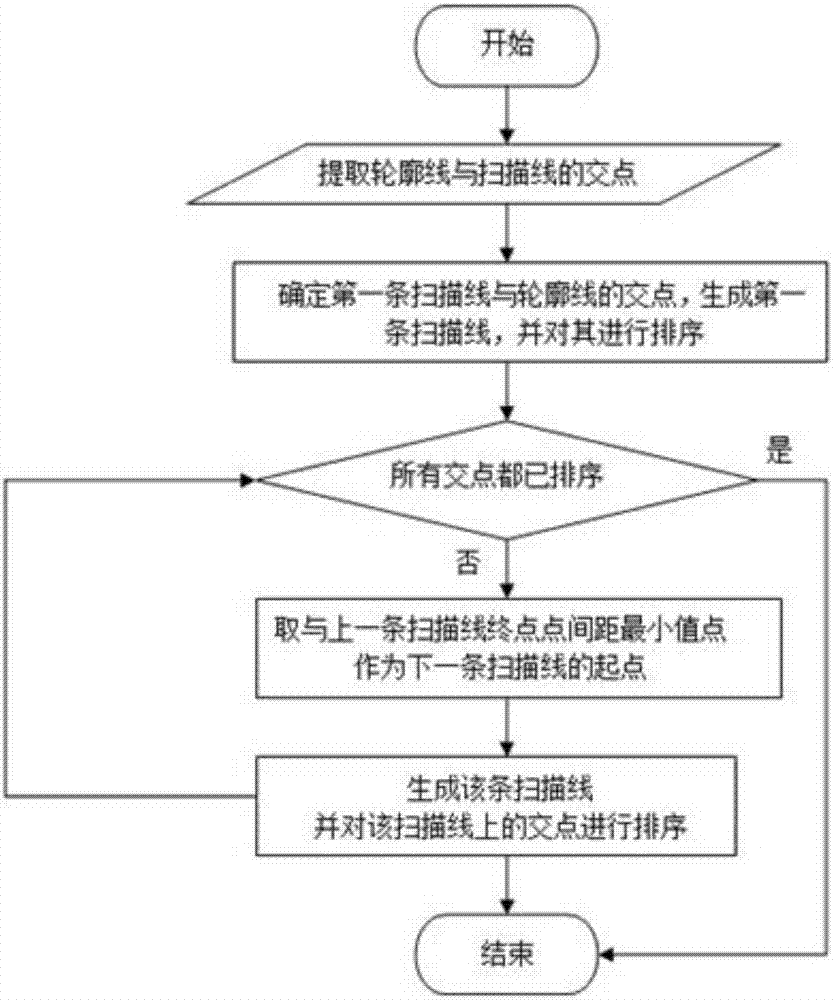

[0041] A kind of LMD laser manufacturing process based on bionic functions, such as figure 1 Shown, concrete steps of the present invention are as follows:

[0042] (1) Solid modeling of molded parts:

[0043] The digital model type of the metal covering layer of the present invention is the digital model type of coaxial powder feeding forming, the powder is evenly dispersed into a ring shape and then converged into the focused laser beam, and falls into the cladding layer after melting, and the powder flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com