High-frequency induction plasma water-cooled quartz lamps

A plasma and high-frequency induction technology, applied in the field of nano-material manufacturing, can solve problems such as maintenance, lamp burnout, lamp burnout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

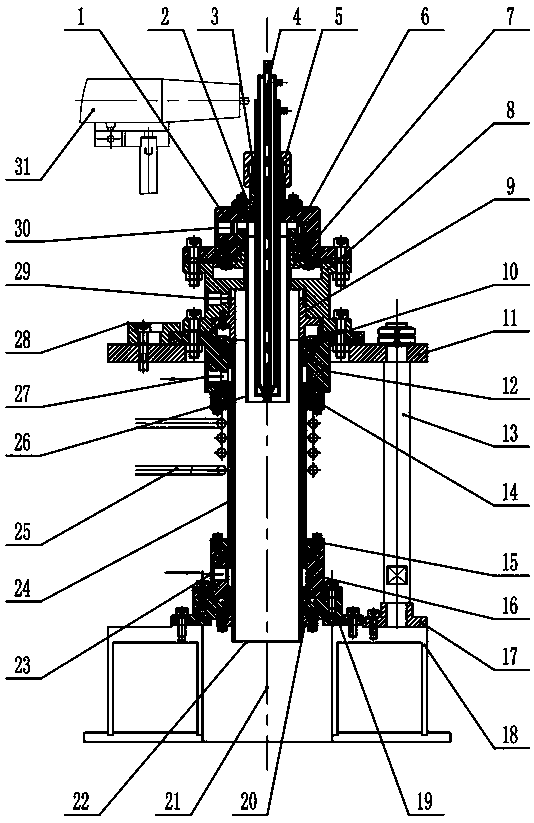

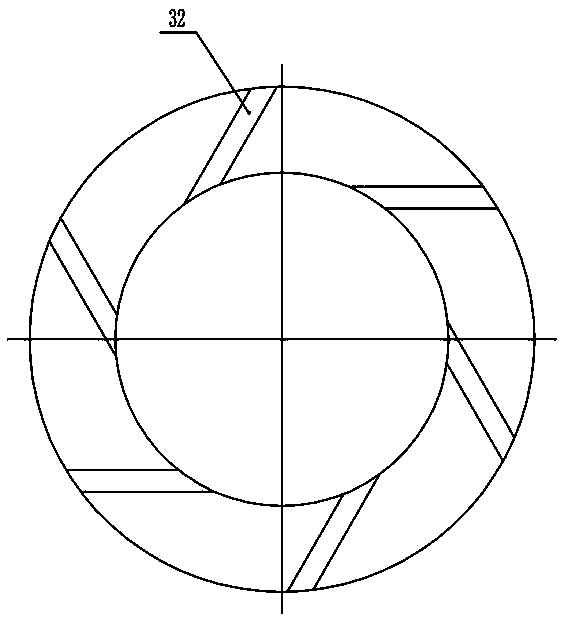

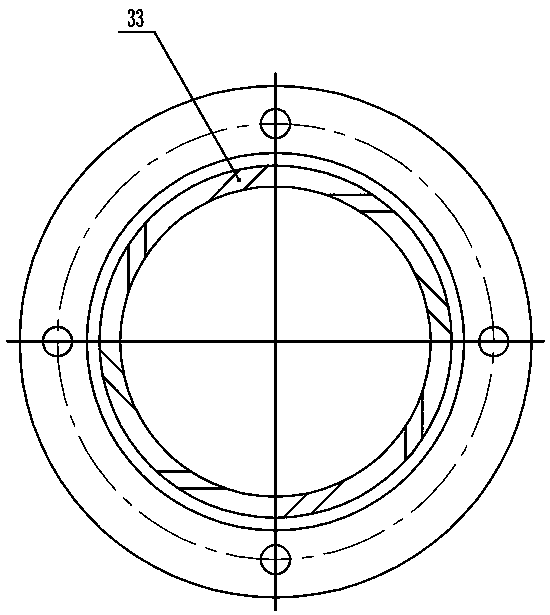

[0023] Such as figure 1 As shown: the high-frequency induction plasma water-cooled quartz lamp includes an upper support 1, a powder gun seat 2, a cone sleeve 3, a powder gun 4, a locking screw sleeve 5, an inner tube sleeve 6, and an inner tube pressure sleeve 7 , middle support 8, shunt pipe 9, middle pipe upper pressure sleeve 10, support plate 11, lower support 12, pillar 13, outer pipe upper pressure sleeve 14, outer pipe lower pressure sleeve 15, base 16, pillar sheath, Water cooling jacket 18, transition plate 19, middle pipe lower pressure sleeve 20, axis 21, middle pipe 22, water inlet 23, outer pipe 24, induction coil 25, inner pipe 26, water outlet 27, pressure plate 28, cooling air inlet 29, The ion gas inlet 30, the igniter 31 and a plurality of sealing rings.

[0024] The outer tube 24 is arranged between the lower support 12 and the base 16, an upper pressure sleeve 14 of the outer tube is arranged at the bottom of the lower support 12, and a lower pressure sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com