Waterproofing treatment method for magnesia-calcium brick

A treatment method, the technology of magnesia-calcium bricks, which is applied in the field of refractory material production, can solve the problems of not being applied to industrial production, etc., and achieve the effects of easier storage, increased bulk density, and improved hydration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

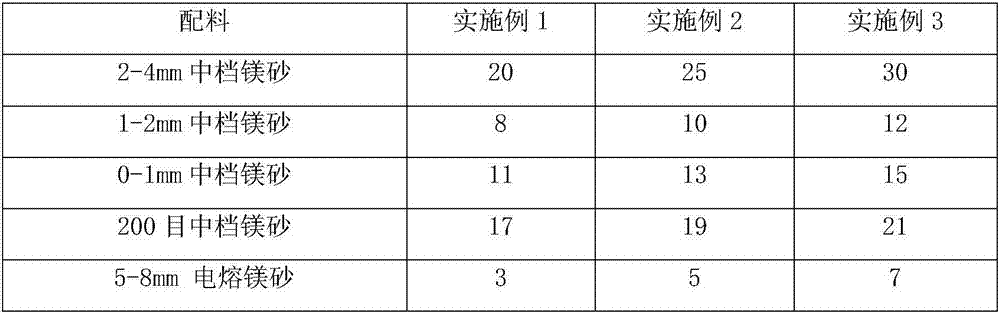

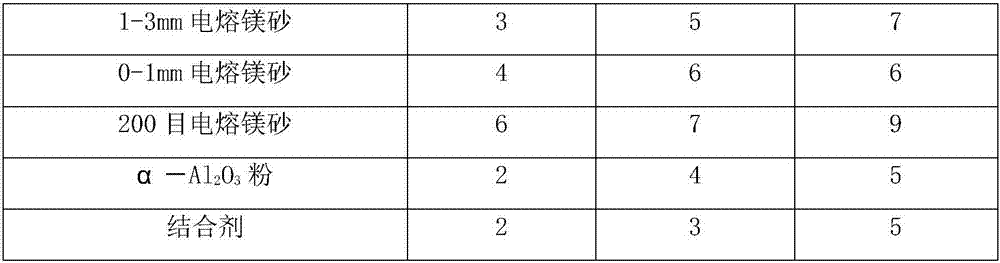

[0016] A waterproof treatment method for magnesia-calcium bricks according to the present invention. The magnesia-calcium bricks are made of the following raw materials in proportions by weight: 20 to 30 parts of magnesia with a particle size of 2 mm ≤ 4 mm, magnesia with a particle size of 1 mm ≤ 2 mm 8-12 parts of sand, 11-15 parts of magnesia with 0mm≤particle size2 o 3 2 to 5 parts of powder; 2 to 5 parts of binder;

[0017] The production process of magnesia-calcium bricks: put magnesia with 2mm≤particle size2 o 3 Powder, kneading for 5-15 minutes; discharging, molding, heat treatment, sorting;

[0018] Waterproof treatment of magnesia-calcium bricks: put the selected magnesia-calcium bricks in a closed container, add waterproofing agent and soak for 2-4 hours, and add 0.1-0.3MPa / cm 2 pressurized penetration; the waterproofing agent is a mixed solution of organosilicon, acetylacetone, and silicate; the proportions of each component are: 85-95 parts of organosilicon; 4-8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com