Prick resistant tire and preparation method thereof

A tire and puncture-resistant technology, which is applied to special tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of poor puncture-resistant effect, high manufacturing cost, and non-aging resistance, and achieve convenient processing and long service life Long, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

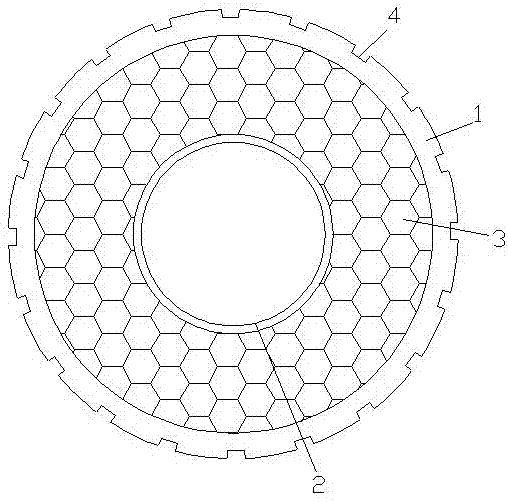

[0021] Such as figure 1 Shown, a kind of puncture resistant tire comprises outer carcass 1, inner carcass 2 and honeycomb structure 3, and described honeycomb structure 3 is arranged between outer carcass 1 and inner carcass 2, and described outer carcass 1, inner carcass 2 and honeycomb structure The structure 3 is integrally formed, the surface of the outer carcass 1 is provided with anti-skid grooves 4, the anti-skid grooves 4 are distributed in a circular array, the thickness of the outer carcass 1 is 2-4cm, and the thickness of the inner carcass 2 is 1cm; The Nezha tire is made of the following materials in parts by weight: 45 parts of styrene-butadiene rubber, 38 parts of brominated butylene rubber, 7 parts of nano clay, 2 parts of zinc oxide, 6 parts of dithiocarbamate, 14 parts of silicon dioxide, 20 parts of ethyl carbamate, 3 parts of sulfur, 18 parts of dimethyl 4-nitrophthalate, 16 parts of pitch, 15 parts of γ-mercaptopropyltrimethoxysilane, graphene fiber 32 par...

Embodiment 2

[0029] Such as figure 1 Shown, a kind of puncture resistant tire comprises outer carcass 1, inner carcass 2 and honeycomb structure 3, and described honeycomb structure 3 is arranged between outer carcass 1 and inner carcass 2, and described outer carcass 1, inner carcass 2 and honeycomb structure The structure 3 is integrally formed, the surface of the outer carcass 1 is provided with anti-skid grooves 4, the anti-skid grooves 4 are distributed in a circular array, the thickness of the outer carcass 1 is 2-4cm, and the thickness of the inner carcass 2 is 1cm; The Nezha tire is made of the following materials in parts by weight: 50 parts of styrene-butadiene rubber, 41 parts of brominated butylene rubber, 9.5 parts of nano clay, 3 parts of zinc oxide, 8 parts of dithiocarbamate, 16 parts of silicon dioxide, 22.5 parts of ethyl carbamate, 4.5 parts of sulfur, 20 parts of dimethyl 4-nitrophthalate, 18 parts of pitch, 17.5 parts of γ-mercaptopropyltrimethoxysilane, graphene fiber...

Embodiment 3

[0037] Such as figure 1 Shown, a kind of puncture resistant tire comprises outer carcass 1, inner carcass 2 and honeycomb structure 3, and described honeycomb structure 3 is arranged between outer carcass 1 and inner carcass 2, and described outer carcass 1, inner carcass 2 and honeycomb structure The structure 3 is integrally formed, the surface of the outer carcass 1 is provided with anti-skid grooves 4, the anti-skid grooves 4 are distributed in a circular array, the thickness of the outer carcass 1 is 2-4cm, and the thickness of the inner carcass 2 is 1cm; The Nezha tire is made of the following materials in parts by weight: 55 parts of styrene-butadiene rubber, 44 parts of brominated butylene rubber, 12 parts of nano clay, 4 parts of zinc oxide, 10 parts of dithiocarbamate, 18 parts of silicon dioxide, 25 parts of ethyl carbamate, 6 parts of sulfur, 22 parts of dimethyl 4-nitrophthalate, 20 parts of asphalt, 20 parts of γ-mercaptopropyltrimethoxysilane, graphene fiber 38...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com