Polyacrylamide-containing expansion material composition, self-suspending proppant, and preparation method and application of self-suspending proppant

A polyacrylamide and swelling material technology, which is applied in drilling compositions, chemical instruments and methods, and earth-moving drilling and mining, etc., can solve the problems of formation pollution, plugging of oil-producing pores, and difficulty in transporting fracturing fluids, reducing the The effect of contamination, viscosity reduction, and transportation difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

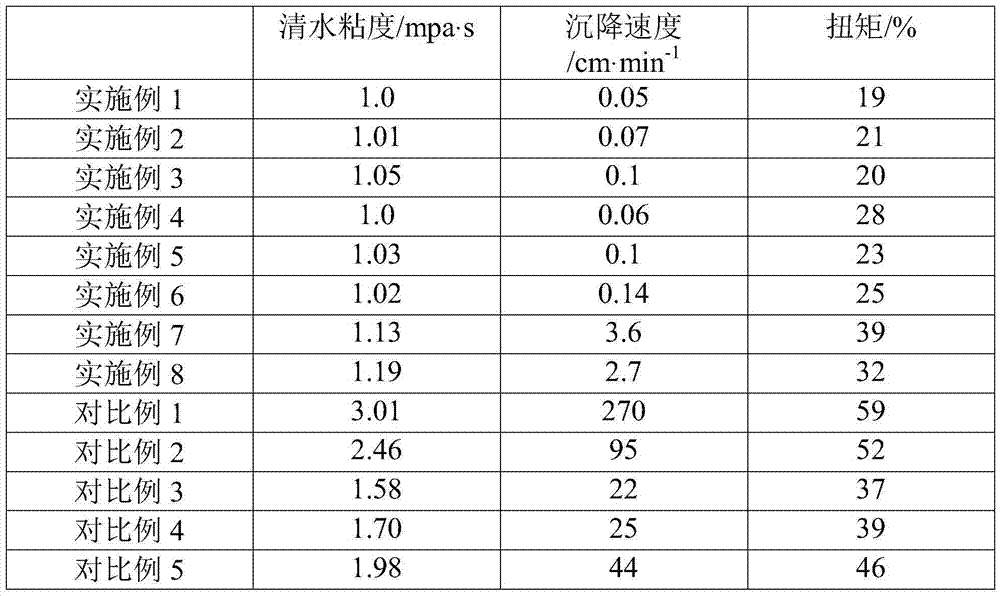

Examples

preparation example Construction

[0027] The present invention also provides the preparation method of above-mentioned self-suspending proppant, and this method comprises the following steps:

[0028] (1) Disperse and mix the proppant body, binder and curing agent uniformly at the first temperature to obtain granular aggregate with binder and / or curing agent attached, wherein, relative to 100 parts by weight of proppant agent body, the amount of the binder is 0.1-15 parts by weight, and the amount of the curing agent is 0.001-1.5 parts by weight;

[0029] (2) Disperse and mix the granular aggregate and the polyacrylamide-containing expansion material composition at a second temperature so that the expansion material composition is coated on the granular aggregate to obtain a granular The self-suspending proppant of the present invention, wherein, relative to 100 parts by weight of the proppant body, the amount of the expansion material composition is 0.1-15 parts by weight.

[0030] The preparation method of ...

Embodiment 1

[0037] This example is used to illustrate the expansion material composition of the present invention and the preparation method and self-suspension proppant prepared from the expansion material composition.

[0038] The expansion material composition in this embodiment is 100 parts by weight of polyacrylamide (weight average molecular weight: 3 million) and 0.1 part by weight of fructooligosaccharide (purchased from Shanghai Emmons Chemical Technology Co., Ltd.).

[0039] (1) Using quartz sand (6-10 mesh in particle size) as raw material, after scrubbing and drying at 120°C for 5 hours, screen 6-40 mesh quartz sand as aggregate;

[0040] (2) Take 100 parts by weight of screened quartz sand, heat it to 240°C, add 0.1 part by weight of epoxy resin E-51 (618), 0.001 part by weight of curing agent phthalic anhydride, stir and mix evenly to obtain a binder package Covered granular aggregate;

[0041] (3) When the temperature of the above-mentioned binder-coated granular aggregate...

Embodiment 2

[0044] This example is used to illustrate the expansion material composition of the present invention and the preparation method and self-suspension proppant prepared from the expansion material composition.

[0045] The expansion material composition in this embodiment is 100 parts by weight of polyacrylamide (weight average molecular weight: 20 million) and 20 parts by weight of corn starch extract (purchased from Zhengzhou Longsheng Chemical Products Co., Ltd.).

[0046] (1) Take 100 parts by weight of ceramsite (particle size is 100-200 mesh), heat to 190 ° C, add 15 parts by weight of binder bisphenol A type unsaturated polyester 3301, add curing agent phthalic anhydride 0.1 parts by weight, stirred and mixed evenly to obtain binder-coated granular aggregate;

[0047] (2) When the temperature of the above-mentioned binder-coated granular aggregate drops to 80° C., add 15 parts by weight of the above-mentioned expansion material composition, and stir and mix evenly.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com