Support vector machine and multi-body dynamics simulation-based high-voltage circuit breaker identification method

A high-voltage circuit breaker and support vector machine technology, applied in character and pattern recognition, design optimization/simulation, instruments, etc., to achieve the effect of reducing workload and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

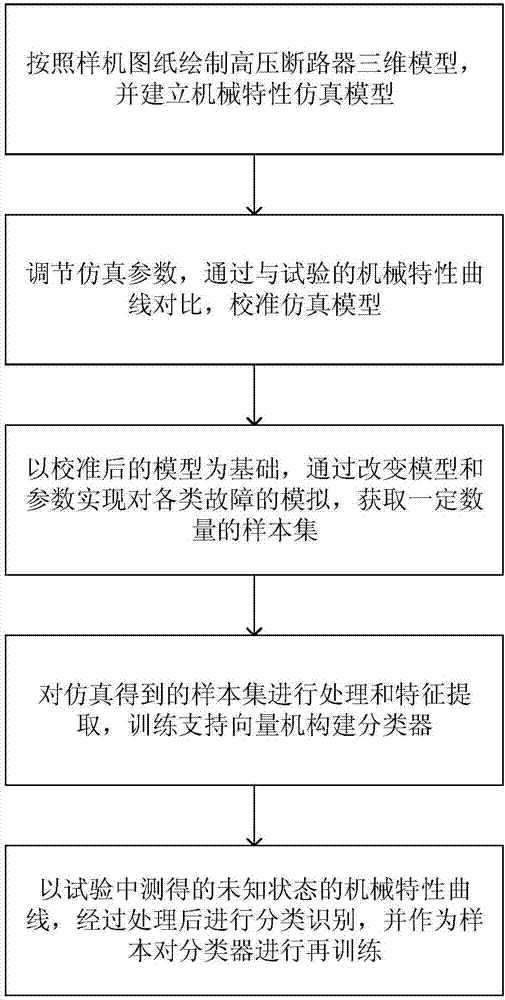

[0046] Such as figure 1 As shown, the high-voltage circuit breaker identification method based on support vector machine and multibody dynamics simulation of the present invention comprises the following steps,

[0047] Step (A), establish a three-dimensional model of the high-voltage circuit breaker, obtain the mechanical characteristic waveform of the three-dimensional model through multi-body dynamics simulation, and compare the simulation results with the test data to calibrate and verify the three-dimensional model, specifically including the following steps,

[0048] (A1) Use 3D modeling software to draw the main circuit of the high-voltage circuit breaker and the components of the operating mechanism, including moving contacts, static contacts, closing and opening holding detents, cams, ratchets, crank arms and Other transmission rods and limit parts, etc.;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com