Buried channel transistor and forming method thereof

A technology of transistors and channels, applied in the field of buried channel transistors and their formation, to improve performance and prevent flicker noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

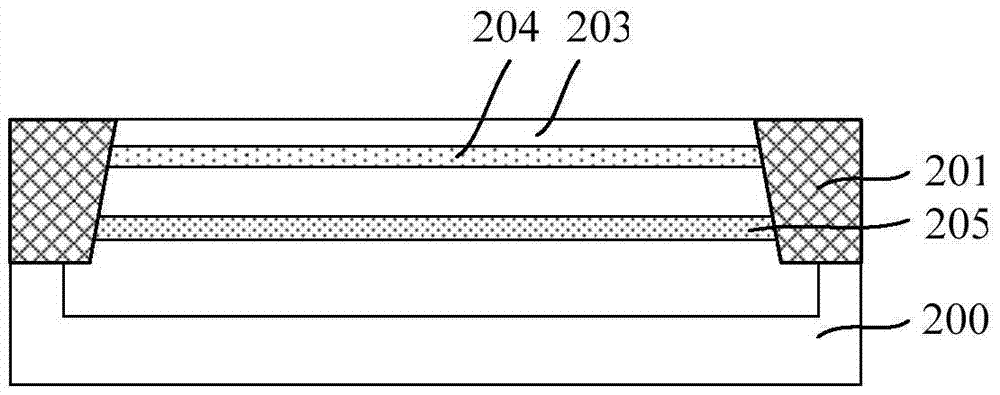

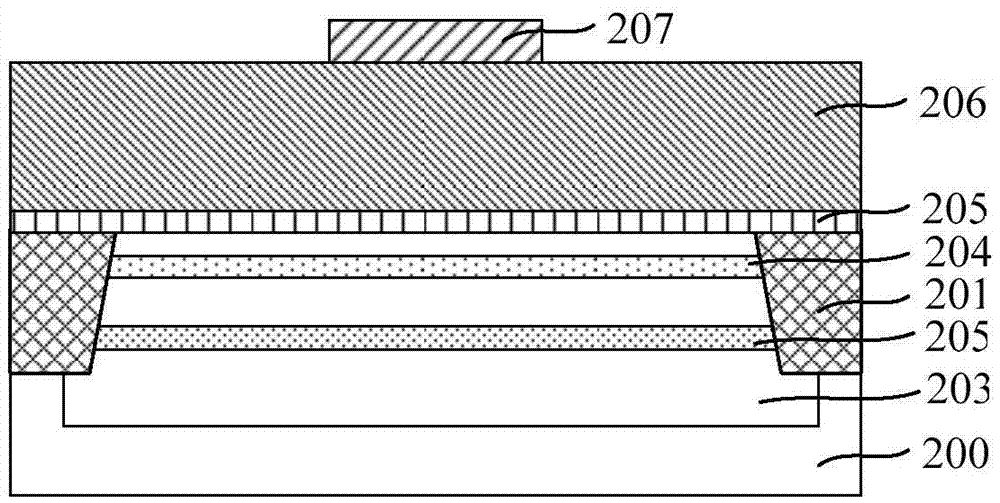

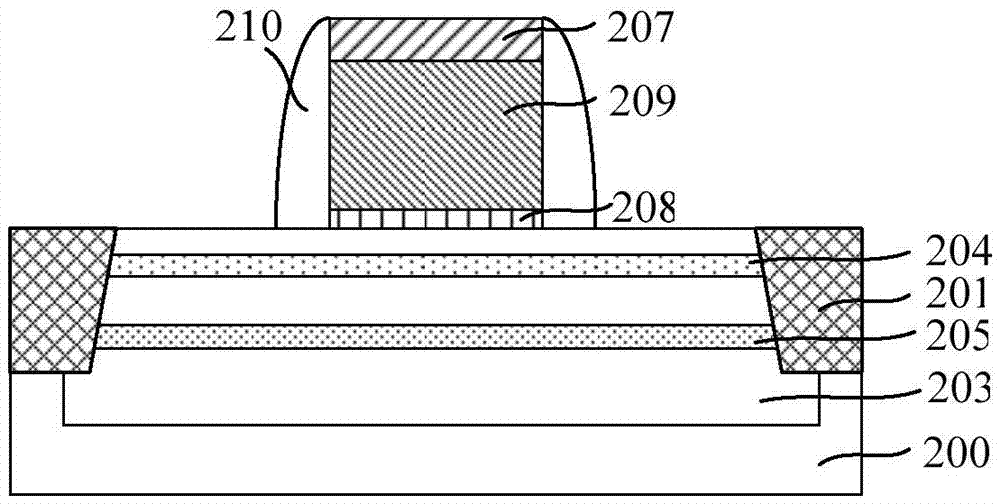

[0030] As mentioned in the background art, the performance of transistors formed by existing technologies still needs to be improved. For example, existing transistors have 1 / f noise or flicker noise during operation, and the generation of 1 / f noise or flicker noise is related to conduction The smoothness of the channel has a great correlation, and the conductive channel formed by the existing transistor is basically a surface channel. In the manufacturing process, it is difficult to ensure the smoothness of the surface of the substrate. There will be defects, and the existence of defects will affect the transport of carriers. Therefore, when the existing transistors are working, flicker noise is likely to occur, which affects the performance of the device.

[0031] To this end, the present invention provides a buried channel transistor and a method for forming the same. By forming an inversion doped region in the well region, the carriers will flow along the gap between the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com