Nail shooting pill for nail fastening device and manufacturing method of nail shooting pill

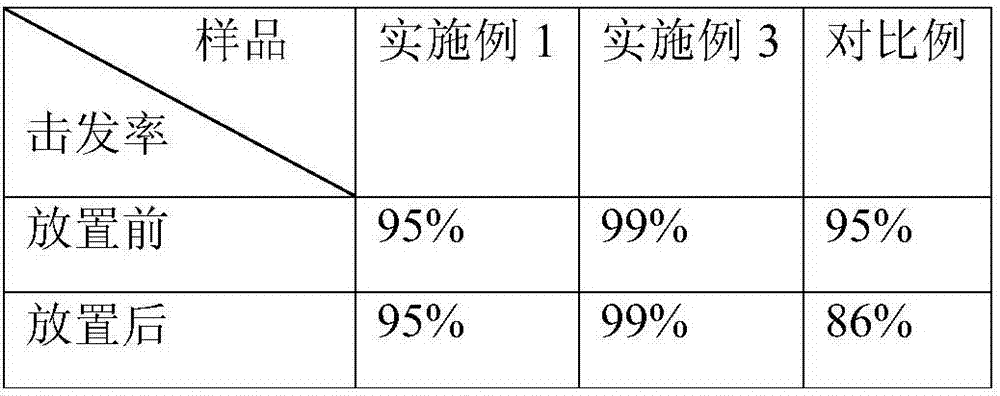

A technology for nail-shooting bombs and fasteners, which is applied in the direction of nailing tools, manufacturing tools, and nitrated explosive components, and can solve the problems of shortening the service life of nail-shooting fasteners, ablation of nail-shooting fasteners, and rupture of protective films, etc. problems, to achieve the effect of improving the use effect and service life, avoiding easy moisture absorption, and reducing the dud rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] For the preferred sealing technology solution, the sealant is heated and melted to a liquid state; the main body of the tablet is heated to about 5-55°C higher than the ambient temperature for a period of time; then the liquid sealant is sprayed on the main body of the tablet, after spraying Cool naturally to normal temperature to obtain the finished nail bullet for nail fasteners with an embedded film. The present invention further provides a method for preparing a moisture-proof plastic-cased nail-shooting bullet containing a nail-shooting bullet for a nail-shooting fastener. The nail-shooting bullet is prepared according to the above-mentioned preparation method, and then the following steps are performed:

[0072] E. Moisture-proof: Press the nail-shooting bullet obtained in step D into the drug chamber of the plastic shell, and immediately dip it in a moisture-proof agent (such as paraffin, ozokerite or refined butter, etc.) with a temperature lower than 60°C to exp...

Embodiment 1

[0073] Example 1 Preparation of nail-shooting bullets for nail-shooting fasteners and moisture-proof plastic-cased nail-shooting bullets

[0074] Based on the weight of nitrocellulose, 1 kg (100%) of Grade B nitrocellulose (dry weight) with a nitrogen content ≥ 13.12%, 80% ethyl acetate, and 20% supplementary water are weighed and measured according to their respective weight percentages .

[0075] Start the kneader, the speed of the kneader is less than 30 rpm, first add nitrocellulose and supplementary water, then add ethyl acetate, and stir the materials evenly for wet plasticization. Pour the wet plasticized material into the dryer, start the hot air blower, the temperature of the heating air is less than 45°C, the hot air passes through the material and takes away the solvent and moisture until the moisture content is lower than 0.8% and the residual solvent content is lower than At 1.3%, stop drying and discharge. Pour the dried material into a compression molding mach...

Embodiment 2

[0080] Based on the weight of nitrocellulose, 1 kg of B-grade nitrocellulose (dry weight) with nitrogen content ≥ 13.12%, 80% acetone, 20% supplementary water, and 1.0% dibutyl phthalate, according to their respective weight percentages Carry out weighing measurement, the sealing agent takes by weighing the paste lubricating grease that is equivalent to 3% of tablet main body weight.

[0081] Add dibutyl phthalate to an appropriate amount of acetone and stir evenly to form a plasticizing solution. Start the kneader, first add nitrocellulose, then add acetone, stir evenly, then add plasticizing solution, continue stirring for wet plasticization, wet plasticization temperature: <35°C, kneader speed <30 rpm.

[0082] All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration depth | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com