Crystallization form of BTK inhibitor, and preparation method thereof

A crystallization and solvent technology, applied in the field of crystal form and preparation of BTK kinase inhibitor, can solve the problems of easy agglomeration, poor product stability, difficult filtration, etc., and achieves repeatable and controllable production process, good crystal form stability, The effect of stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (R)-1-(3-(4-Amino-3-(4-(2,6-difluorophenoxy)phenyl)-7-hydroxy-1H-pyrrolo[2,3-d]pyridine Synthesis of oxazin-1-yl)piperidin-1-yl)propyl-2-en-1-one

[0038] The first part: the preparation of compound 1e

[0039]

[0040] Step A

[0041] Sodium acetate ethanol solution (160ml, mass fraction 21%, 0.49mmol) was added to 110ml ethanol, and diethyl oxalate (64ml, 0.47mol) was added under ice-bath condition. The mixture was stirred for 30 min. A solution of (16 g, 0.15 mmol) (E)-hex-3-enenitrile 1a in (30 ml) ethanol was then added to the mixture. Stir overnight at room temperature. After cooling in an ice bath, the suspension was filtered. The solid was washed with a small amount of ethanol, then dissolved in 380 ml of water, and acidified to pH 4 with hydrochloric acid. A large amount of solid precipitated out which was filtered, washed with water and dried to give 11.9 g of yellow solid 1b.

[0042] Step B

[0043] To (2.3g, 7.5mmol) 1b in (120ml) ethyl acetate s...

Embodiment 2

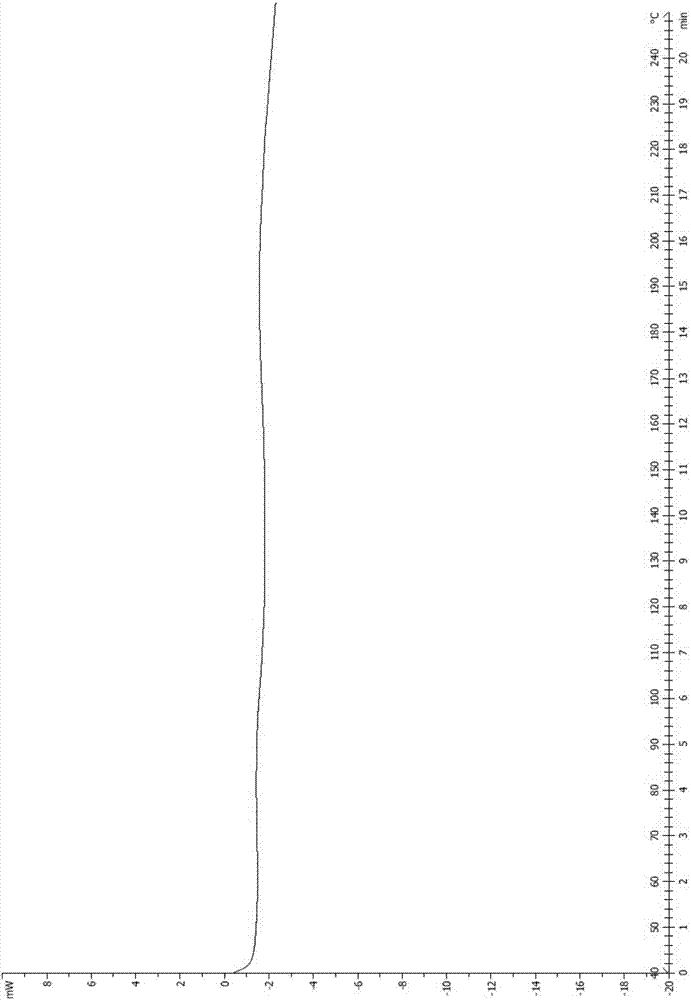

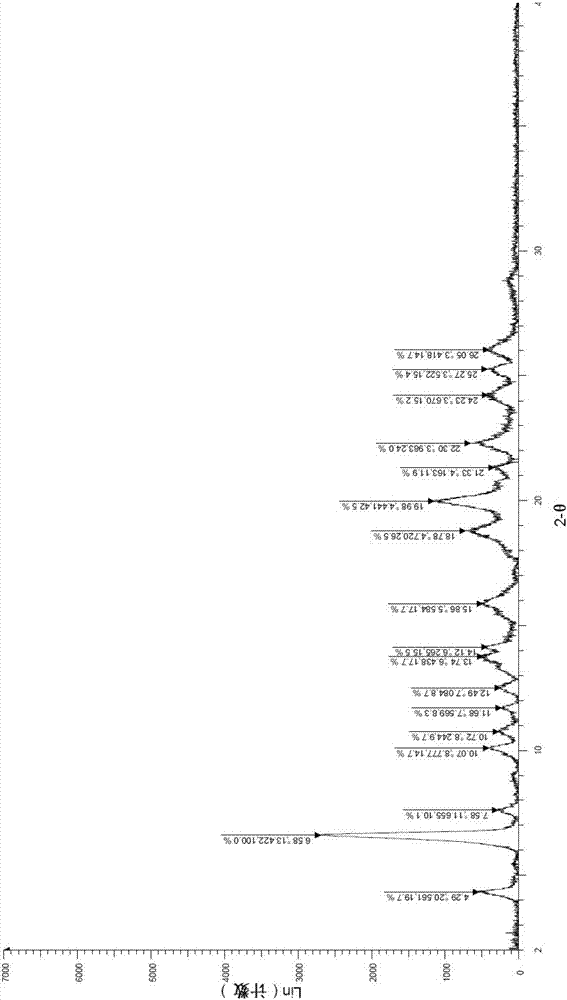

[0069] Take 300mg of the compound represented by formula (I) (prepared according to Example 1) in a 25ml single-necked bottle, add 2ml of ethanol, heat to dissolve, cool down to crystallize, and stir overnight. The next day, it was suction filtered and dried to obtain 241 mg of solid, with a yield of 80.3%. For the X-ray diffraction of this crystalline sample see image 3 , where at about 4.29(20.56), 6.58(13.42), 7.58(11.66), 10.07(8.78), 10.72(8.24), 11.68(7.57), 12.49(7.08), 13.74(6.44), 14.12(6.26), 15.86 There are characteristic peaks at (5.58) and 19.98 (4.44). See the DSC spectrum Figure 4 , there is a melting endothermic peak around 141°C, and this crystal form is defined as I crystal form.

Embodiment 3

[0071] Take a 300 mg sample of the compound represented by formula (I) (prepared according to Example 1) in a 25 ml single-necked bottle, add 3 ml of methanol, heat to dissolve, cool down to crystallize, and stir overnight. The next day, it was filtered with suction and dried to obtain 165 mg of solid, with a yield of 55.0%. The X-ray diffraction and DSC patterns of the crystalline sample are studied and compared, and it is determined that the product is the I crystal form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com