Technology for producing biogas from organic waste reinforced by lime mud from papermaking process

A technology of organic waste and paper-making white mud, applied in fermentation, waste fuel, etc., can solve the problems of small gas production, complex microorganisms are easily affected by acidified environment, and start-up failure, so as to improve gas production capacity, realize double waste reduction and The effect of waste recycling application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

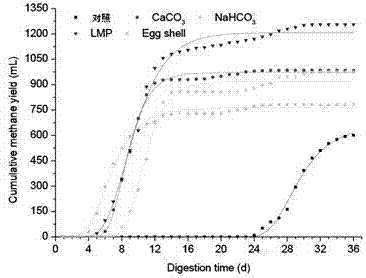

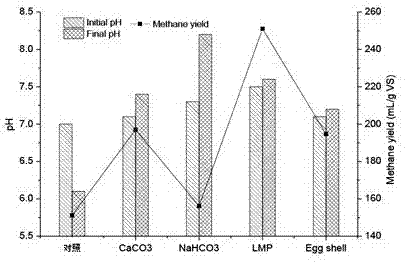

[0031] Comparative experimental scheme of different additives

[0032] Preparation before experiment:

[0033] (1) Prepare LMP powder with a particle size of 70 mesh;

[0034] (2) Acclimate the inoculum sludge at 37 degrees Celsius;

[0035] (3) Disperse the organic waste, and the particle size of the organic waste is about 2.0 mm.

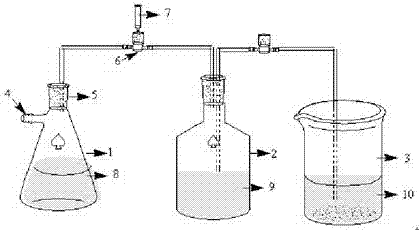

[0036] Experimental procedure:

[0037] (1) Take 4.0 g of alkaline additives (CaCO3, NaHCO3, LMP, and egg shells) of the same quality and put them into reactors with an effective volume of 500 mL. Take another same reactor without adding any exogenous alkaline substance as a control, and number it accordingly;

[0038] (2) Add an appropriate amount of deionized water to the marked numbered reactors to dissolve and dilute the additives;

[0039] (3) Accurately weigh 200 g of evenly mixed organic waste test raw materials and 20% (based on the effective volume of the reactor) inoculated sludge, and move them into each reactor in turn, and use de...

Embodiment 2

[0046] At 37 degrees Celsius, a comparative experiment scheme using different concentrations of LMP as an additive:

[0047] Preparation before experiment:

[0048] (1) Prepare LMP powder with a particle size of 70 mesh;

[0049] (2) Acclimate the inoculum sludge at 37 degrees Celsius;

[0050] (3) Disperse the organic waste, and the particle size of the organic waste is about 2.0 mm.

[0051] Experimental procedure:

[0052] This program adds different amounts of LMP to the organic waste anaerobic digestion system to investigate the effect of LMP addition on the performance of the organic waste mesophilic (37 ℃) anaerobic digestion system, and further explores the buffering effect of LMP on the organic anaerobic methanogenesis system. ability.

[0053] (1) Weigh different amounts of LMP powder (1.0 g, 3.0 g, 5.0 g, 7.0 g) and put them into reactors with an effective volume of 500 mL. Take another same reactor without adding LMP as a control test, and number them respecti...

Embodiment 3

[0061] At 55 degrees Celsius, a comparative experiment scheme using different concentrations of LMP as an additive:

[0062] Preparation before experiment:

[0063] (1) Prepare LMP powder with a particle size of 70 mesh;

[0064] (2) Acclimate the inoculum sludge at 55 degrees Celsius;

[0065] (3) Disperse the organic waste, and the particle size of the organic waste is about 2.0 mm.

[0066] Experimental procedure:

[0067] This program adds different amounts of LMP to the organic waste anaerobic digestion system to investigate the effect of LMP addition on the performance of the organic waste mesothermal (55 ℃) anaerobic digestion system, and further explores the buffering effect of LMP on the organic anaerobic hydrogen production system ability.

[0068] (1) Weigh different amounts of LMP powder and place them into reactors with an effective volume of 500 mL. Take another same reactor without adding LMP as a control test, and number them respectively;

[0069] (2) Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com