Bulletproof armor device integrating synergy deformation clamp

A bulletproof and armored plate technology, which is applied to the structure, armor, protective equipment and other directions of the armored plate, can solve the problems of large deformation of the bulge of the back plate and the surrounding tightening, so as to increase the bulletproof ability and facilitate installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

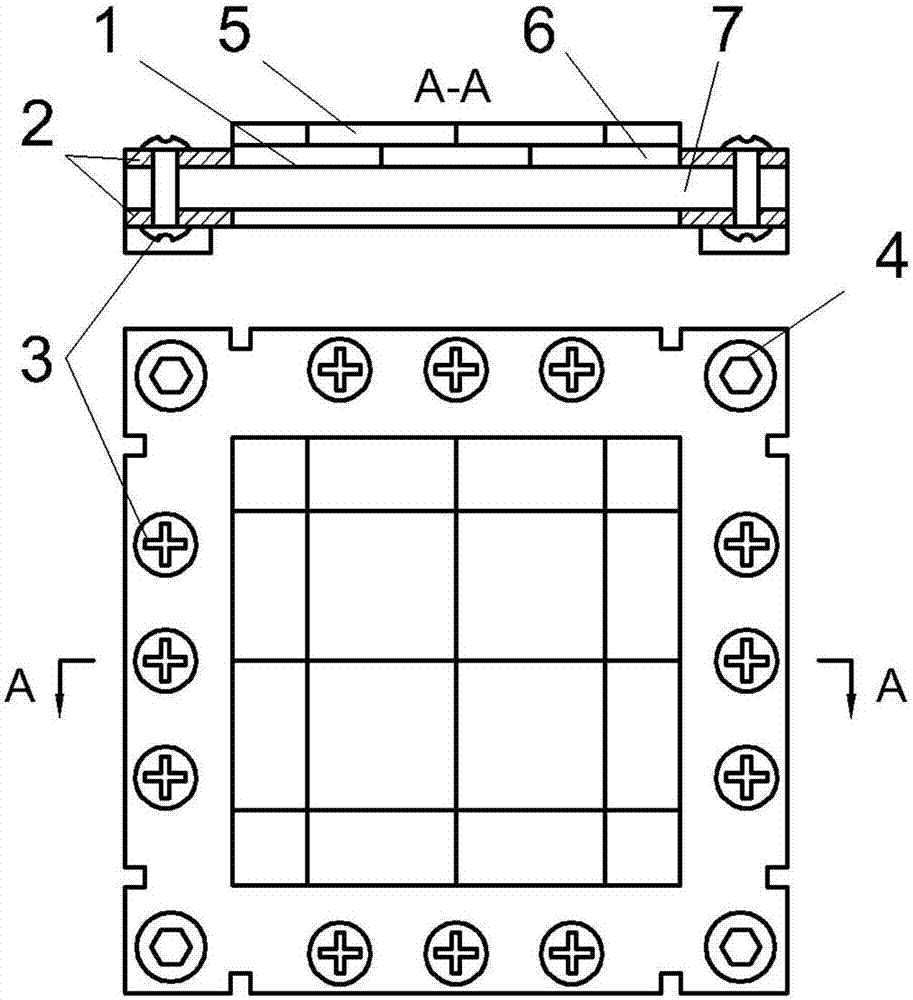

[0031] The invention provides a device for coordinating the deformation and energy absorption of laminated plates of composite materials. Its specific structure includes: an armor plate 1, an annular frame cooperating deformation clamp 2, rivets 3 and bolts 4, and the armor plate is installed as follows: figure 1 As shown, the A-A sectional view of this schematic diagram has removed the fastening bolts; wherein the armor plate 1 includes: the first layer of ceramic panels 5, the second layer of ceramic panels 6 and the back plate ultra-high molecular weight polyethylene laminate 7, the armor plate The size is small, and the specific size can be adjusted according to the bulletproof requirements.

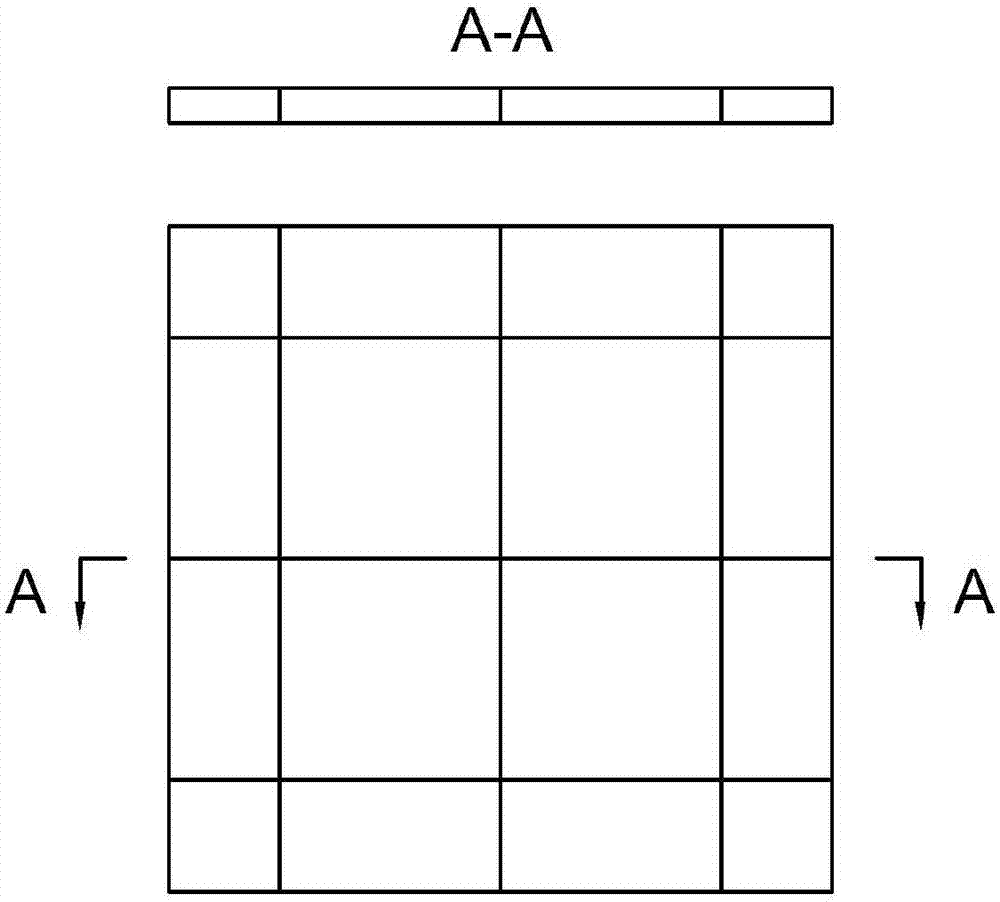

[0032] The first layer of ceramic panels 5 is spliced by large square ceramics, rectangular ceramics and small square ceramics, the area of the small square ceramics is 1 / 4 of the large square ceramics, and the area of the rectangular ceramics is 1 / 2 of the large square ceramics...

Embodiment 2

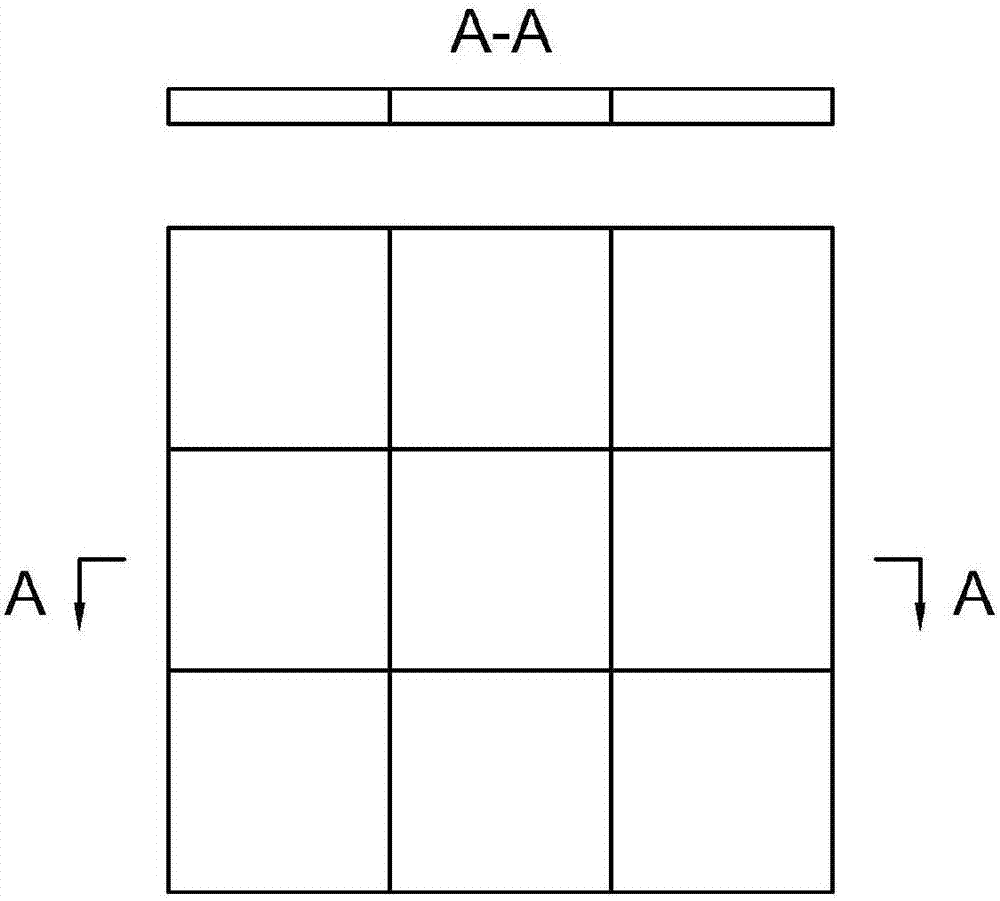

[0041] The invention provides a device for coordinating the deformation and energy absorption of laminated plates of composite materials. The specific structure includes: an armor plate 1, an annular frame cooperative deformation fixture 2, rivets 3 and bolts 4, wherein the armor plate includes: a first layer of ceramic panels 5. The second layer of ceramic panel 6 and the back panel ultra-high molecular weight polyethylene laminate 7, but compared with Example 1, the size of the armor plate in Example 2 is increased; after the armor plate is impacted, the back of the laminate will bulge , four-sided tightening, interlayer separation and other failure phenomena, because the laminate at this time is thicker, the backside interlayer separation will become more serious.

[0042] Armor plate with increased size and thicker thickness, in which the overall size of the ceramic panel is 250×250×12mm, the spliced ceramics used are the same as in Example 1, the area of the laminated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com