Proton exchange membrane fuel cell membrane electrode sealing frame

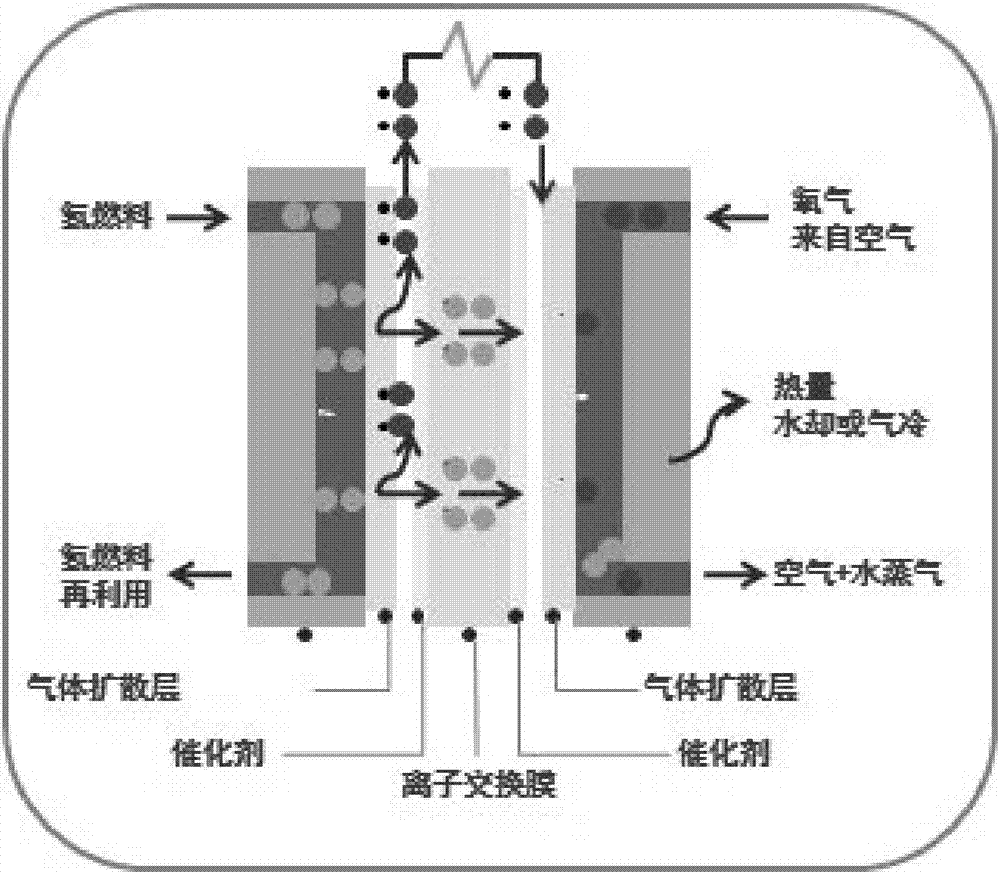

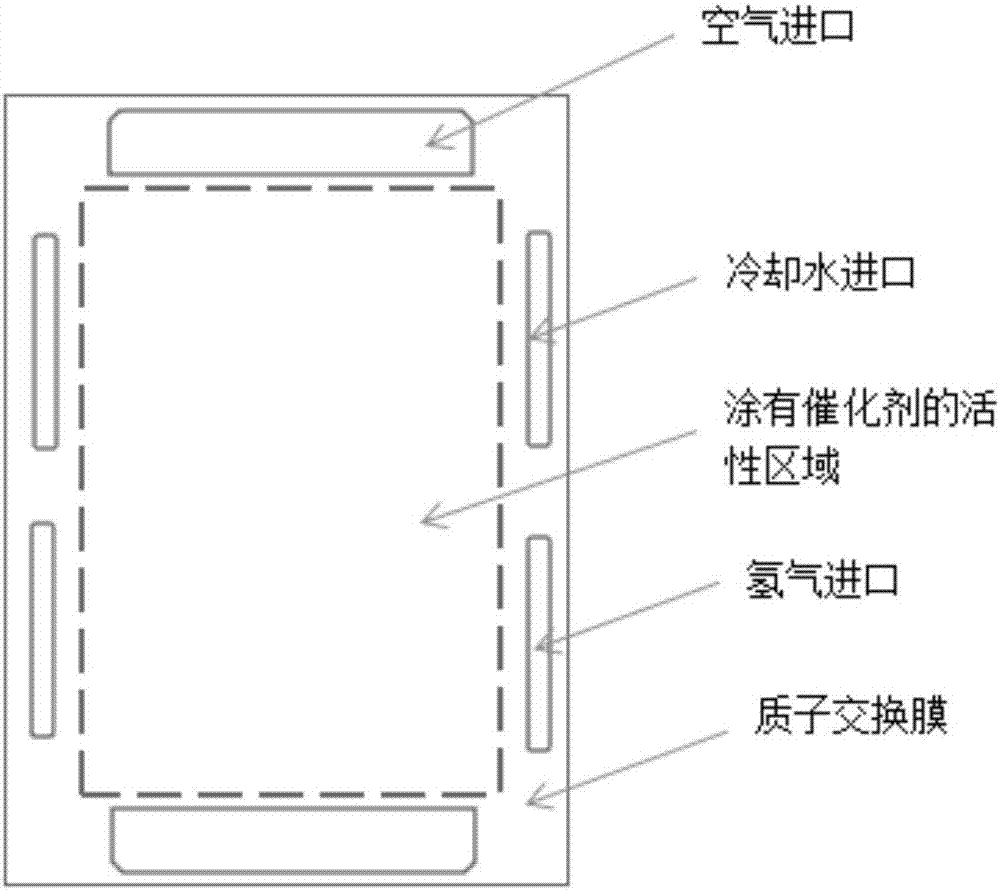

A proton exchange membrane and fuel cell membrane technology, applied in the field of proton exchange membrane fuel cell membrane electrode sealing frame, can solve the problems of difficult sealing layer, proton exchange membrane failure, difficult operation, etc., and achieve process-oriented processing and structure Reasonable design and excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a frame without external sealing effect

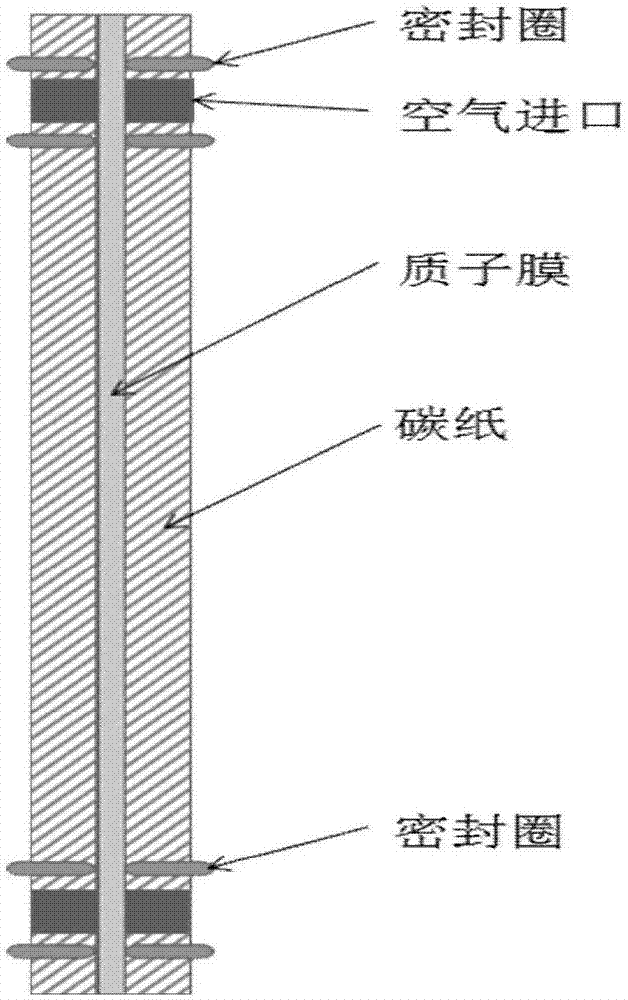

[0034] Figure 5 It is a schematic diagram of the structure of the present invention: the preparation method is prepared from the inside out. First, a proton exchange membrane with a catalytic layer is prepared and placed between a piece of polyimide film padding layer, and docked with its end. The thickness of the polyimide is 40 microns, then a layer of double-sided adhesive adhesive layer is arranged on the left and right sides of the proton exchange membrane and the leveling layer, and a layer of polyimide film protective layer of the same thickness is respectively arranged on the outer side of the adhesive layer. The thickness of the protective layer is is 25 microns. Then the gas diffusion layer is arranged on the outer side of the protective layer, placed into a clamp for clamping and then placed on a flat heat press machine. Set the hot pressing time to 120s, the pressure to 1.5MPa, the temperatu...

Embodiment 2

[0036] A method for preparing a frame with both external and internal sealing functions

[0037] Figure 5It is a schematic diagram of the structure of the present invention: the preparation method is prepared from the inside out. First, the proton exchange membrane with the catalytic layer is prepared and placed between a piece of polypropylene film padding layer, and docked with its end. The thickness of the polypropylene is 30 microns, and then A layer of double-sided adhesive adhesive layer is arranged on the left and right sides of the proton exchange membrane and the leveling layer, and a layer of polypropylene film protective layer of the same thickness is respectively arranged on the outer side of the adhesive layer, and the thickness of the protective layer is 50 microns. A double-sided adhesive layer is arranged on the outer sides of the protective layers on both sides, and the sealing layer of styrene-butadiene rubber is arranged on the outer side of the adhesive la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com