Method of producing super-hydrophobic/oleophylic oil-water separation mesh membrane through one-step electro-deposition

A super-hydrophobic, electrodeposition technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of expensive processing equipment, complicated operation process, harsh preparation conditions, etc., and achieve the goal of being suitable for large-scale applications and The effect of simple promotion and process preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

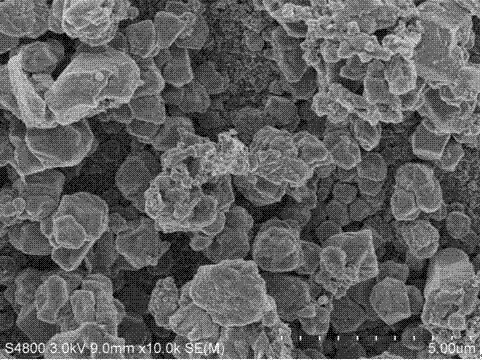

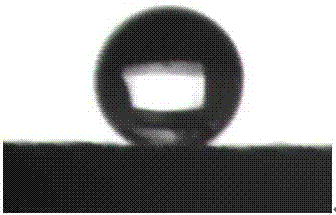

Embodiment 1

[0019] Cut the 200-mesh 304 stainless steel mesh into a size of 5cm×4cm, and cut the copper sheet into a size of 5cm×4cm×0.1cm, respectively, ultrasonically clean with acetone, ethanol and deionized water for 15 minutes to remove the oil stains on the surface of the metal mesh and copper sheet. Then put the metal mesh into 4mol / L hydrochloric acid for chemical polishing for 5min, then take it out, rinse it with deionized water, and dry it for later use. Then 2.6285g of nickel sulfate was added to 75ml of deionized water, and after dissolving, 25ml of n-dodecanethiol ethanol solution with a concentration of 2ml / L was added, and then 0.1g of dopamine was added under stirring to obtain an electrolyte solution. Finally, the pretreated metal mesh substrate and copper sheet were placed in an electrodeposition device as cathode and anode, respectively, and ultrasonically deposited at a frequency of 60 Hz for 10 min at a current density of 0.04 A. The substrate was taken out and the r...

Embodiment 2

[0021] Cut the 80-mesh copper mesh into a size of 5cm×4cm, and cut the copper sheet into a size of 5cm×4cm×0.1cm. Use acetone, ethanol and deionized water for ultrasonic cleaning for 15 minutes to remove the oil stains on the surface of the metal mesh and the copper sheet. The metal mesh was chemically polished in 6 mol / L sulfuric acid for 8 min, then taken out, rinsed with deionized water, and dried for later use. Then, 0.6575g of nickel sulfate was added to 40ml of deionized water, and after dissolving, 10ml of hexadecanethiol ethanol solution with a concentration of 6ml / L was added, and then 0.08g of dopamine was added under stirring to obtain an electrolyte solution. Finally, the pretreated metal mesh substrate and copper sheet were placed in an electrodeposition device as cathode and anode, respectively, and ultrasonically deposited at a frequency of 50 Hz for 15 min at a current density of 0.01 A. The substrate was taken out and the residual solution on the surface was r...

Embodiment 3

[0023] Cut the 400-mesh 304 stainless steel mesh into a size of 5cm×4cm, and cut the copper sheet into a size of 5cm×4cm×0.1cm, and ultrasonically clean with acetone, ethanol and deionized water for 15min respectively to remove the oil stains on the surface of the metal mesh and the copper sheet. Then put the metal mesh into 8mol / L hydrochloric acid for chemical polishing for 10min, then take it out, rinse it with deionized water, and dry it for later use. Then, 0.4754g of nickel chloride was added to 50ml of deionized water, and after dissolving, 10ml of 10ml / L tetradecanethiol ethanol solution was added, and then 0.1g of dopamine was added under stirring to obtain an electrolyte solution. Finally, the pretreated metal mesh substrate and copper sheet were put into an electrodeposition device as cathode and anode, respectively, and ultrasonically deposited at a frequency of 60 Hz for 10 min at a current density of 0.2 A. The substrate was taken out and the residual solution on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com