Disposer for removing rubbish adhered on spring flexible shaft and retracting method of spring flexible shaft of dredging trolley

A processor and flexible shaft technology, which is applied in the field of spring flexible shaft garbage adhesion processor and the recovery of the spring flexible shaft of the wrecker truck, can solve the problem of affecting the quality and service life of the dredging machine, affecting the hygiene of the wrecking vehicle, and delaying the time of wrecking the wrecker. and other problems, to achieve the effect of shortening the waste disposal time, optimizing the method of dredging, and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

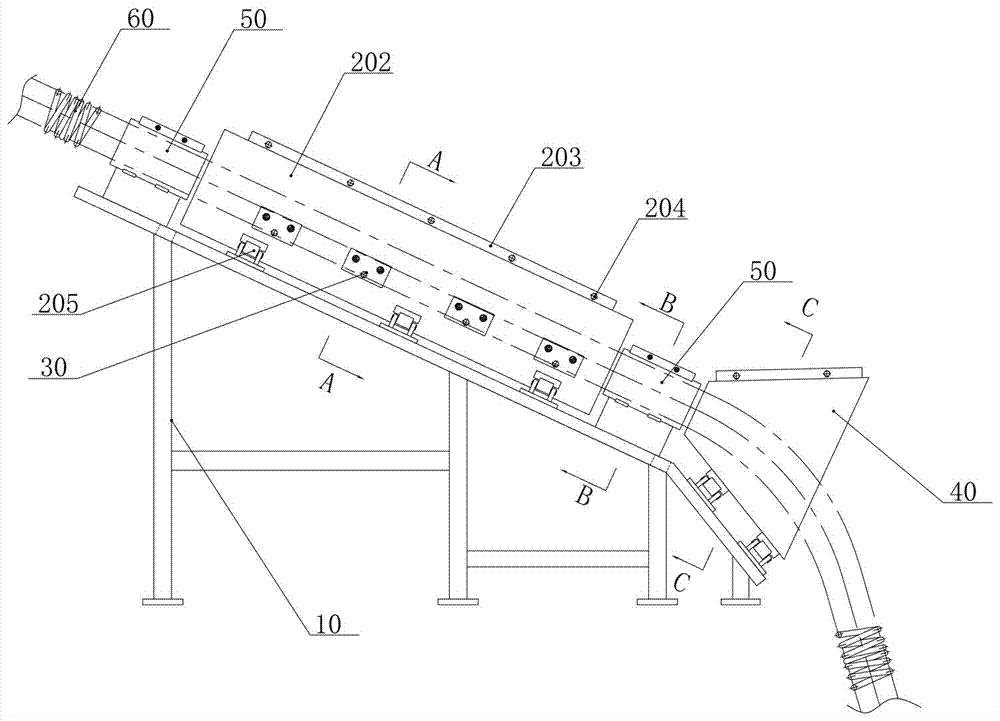

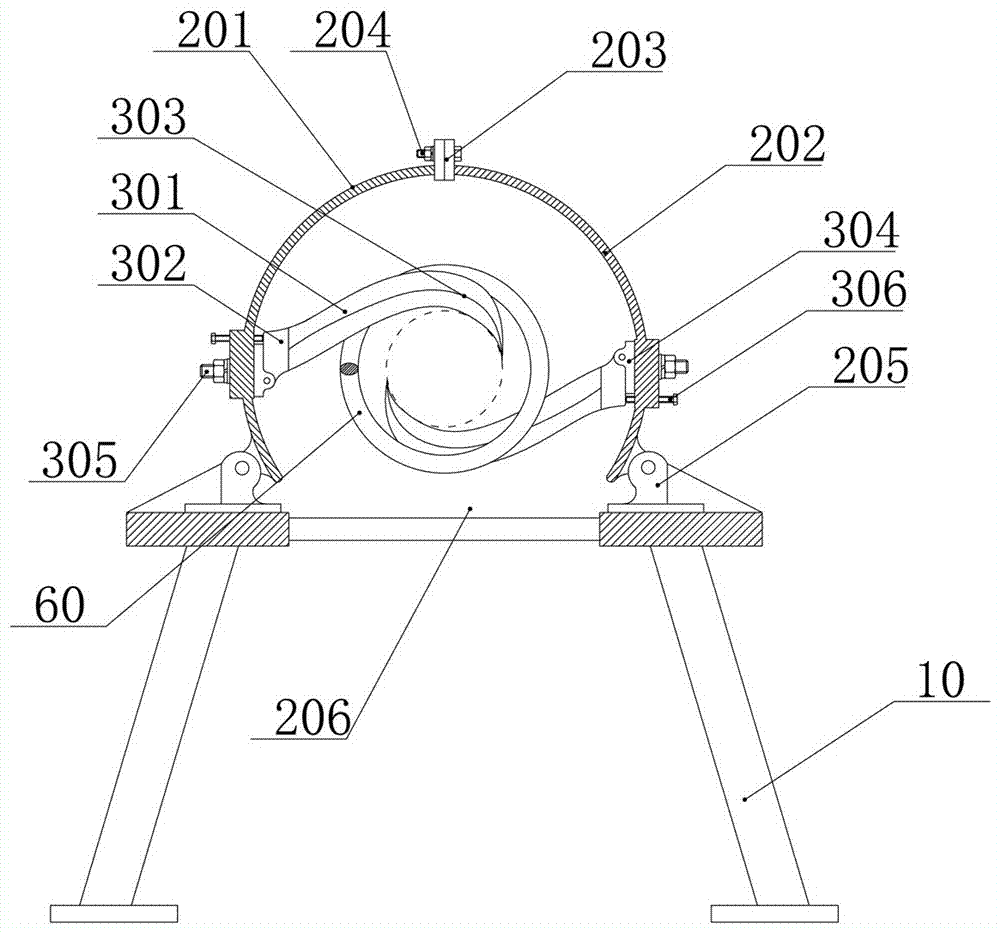

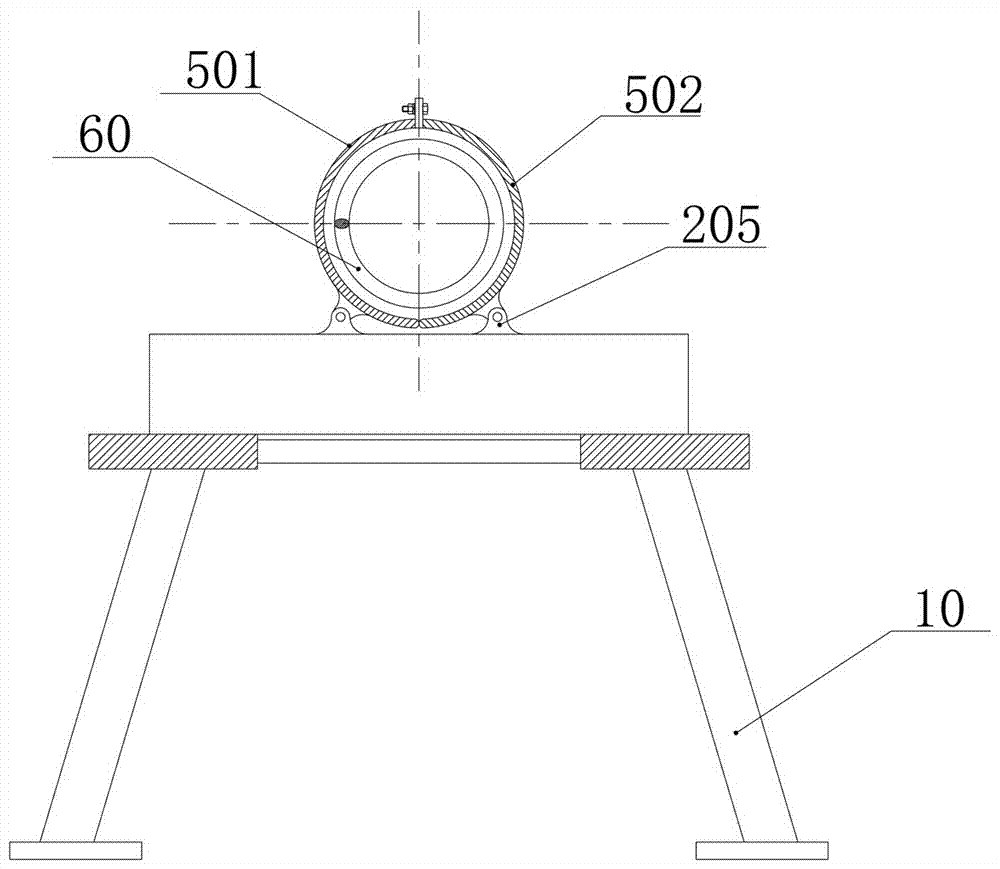

[0031] Example 1: see Figure 1-Figure 4 , a spring flexible shaft garbage adhesion disposer, comprising a bracket 10, a left shell 201 and a right shell 202 correspondingly arranged on the bracket 10, and a hook knife assembly 30 arranged in the left shell 201 and the right shell 202 , the bottom of the left casing 201 and the right casing 202 is provided with a blanking channel 206; the hook knife assembly 30 includes a plurality of hook knives arranged in the axial direction, and the hooks arranged in the left casing 201 and the right casing 202 The knives are arranged in a staggered manner, and the hook knives are matched and inserted into the spring gap of the spring flexible shaft 60 .

[0032] In this embodiment, the hook knife includes a knife seat 302, a hook knife body 301 matching the helix angle β of the spring flexible shaft, and an arc-shaped hook knife head 303 disposed at the front end of the hook knife body 301. The left shell 201 The hook knives in the right...

Embodiment 2

[0040] Embodiment 2: A method for recovering the spring flexible shaft of a wrecker truck using the spring flexible shaft garbage adhesion processor in the above embodiment, after the pipeline clearing truck has completed the pipeline dredging work, it is necessary to rewind the spring flexible shaft And clean the spring flexible shaft, which includes the following steps:

[0041] ① Transport the spring flexible shaft garbage adhesion disposer to the front of the manhole and fix it, open the left and right casings, the left and right peeling cylinders, the left and right guide cylinders, and fit the spring flexible shaft into the Between the left casing and the right casing, at the same time, each hook knife is matched and inserted into the spring gap of the spring flexible shaft, and then each component is closed to complete the assembly and connection of the spring flexible shaft garbage adhesion processor and the spring flexible shaft;

[0042] ②Start the power unit of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com