Method for synchronously separating chloroplast and mitochondria of high purity plant

A synchronous separation and chloroplast technology, applied in the field of cell biology and molecular biology, can solve the problems of long centrifugation time, high price, and medium osmotic pressure sensitivity, and achieve the effect of ensuring activity, simple operation and simple consumables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The embodiment of the present invention takes rapeseed leaf tissue as an example, and this method is also applicable to the simultaneous separation of chloroplasts and mitochondria of Arabidopsis, tobacco, rice, wheat and other plants.

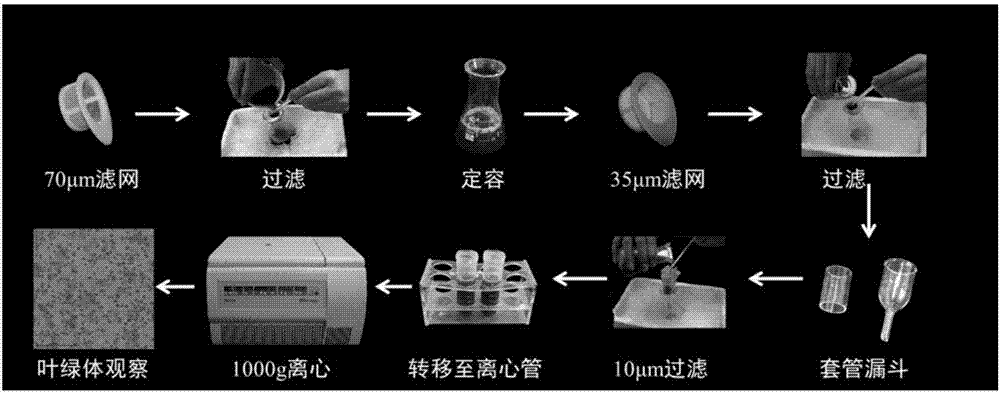

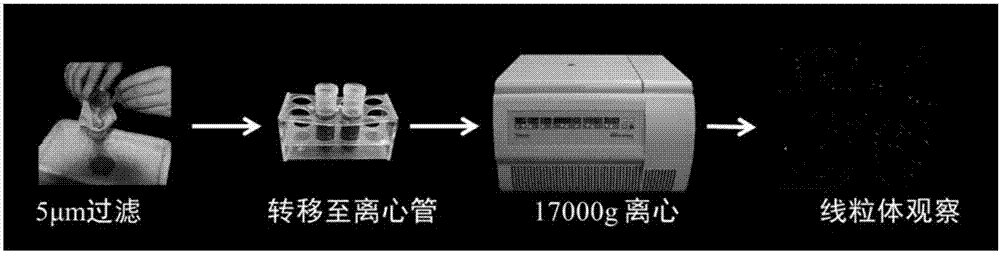

[0027] A method for synchronously separating high-purity plant chloroplasts and mitochondria, the steps of which are:

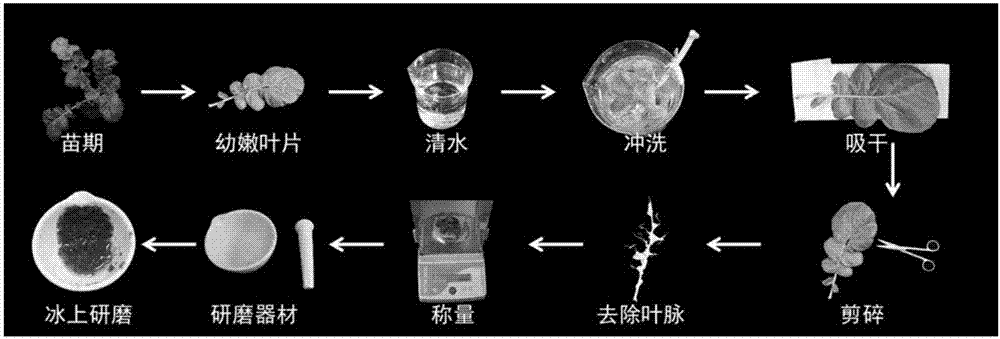

[0028] 1. Leaf tissue processing and grinding

[0029] During the physiological growth period of plants, the young leaf tissue of rapeseed was selected as the material for separating and purifying chloroplasts and mitochondria. After cutting the leaf tissue, put it on ice for temporary storage, rinse it several times with clean water, and clean the soil and other impurities on the leaf. Afterwards, use absorbent paper to absorb the remaining water drops on the leaves, and then use sterilized surgical scissors to cut the non-vein parts into pieces, weigh 5g and place them in a sterilized mortar, and add pre-cooled CIB ...

Embodiment 2

[0034] Example 2: Observation of chloroplasts and mitochondria

[0035] Separate 100 μL of the chloroplast and mitochondria isolated in Example 1, add 10 μL RedCMXRos was incubated at room temperature in the dark for 10 minutes, then washed twice with washing buffer, and prepared for observation under a confocal laser microscope. Observation results show that the rape leaf chloroplast purity that uses the separation of the present invention is higher ( Figure 4 A), with very little mitochondrial contamination ( Figure 4 A-3 and Figure 4 A-4), and the chloroplasts are complete and active ( Figure 4 A-1, Figure 4 A-2 and Figure 4 A-4); the mitochondria isolated synchronously have extremely high purity, no chloroplast pollution, and are active ( Figure 4 B-3 and Figure 4 B-4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com