Copper ferrite/carbon nanofiber membrane and preparation method and application thereof

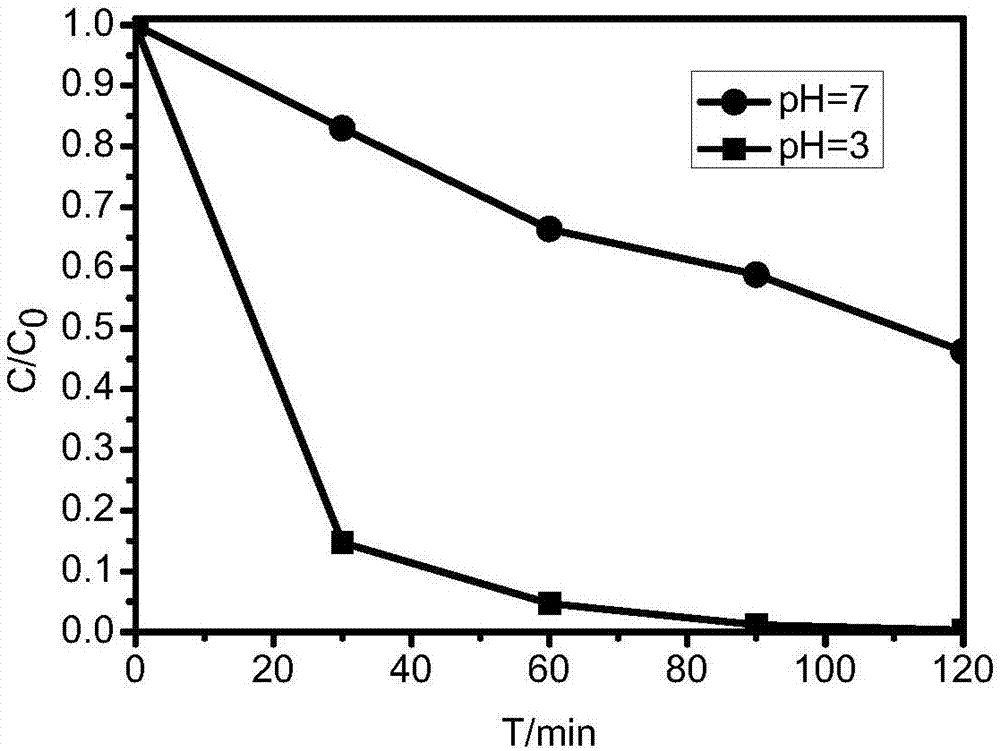

A carbon nanofiber, copper ferrite technology, applied in fiber processing, filament/wire forming, heating/cooling fabrics, etc., can solve the problems of difficult recovery of electro-Fenton catalysts, avoid catalyst loss and recovery difficulties, implement Simple, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A preparation method of copper ferrite / carbon nanofiber film, which comprises:

[0017] Add copper salt and iron salt to the mixture of polymer and N, N-dimethylformamide, and mix to obtain an electrospinning solution. The electrospinning solution is subjected to electrospinning to obtain a metal salt / polymer fiber film, and the metal salt / polymer fiber film is heat-treated and annealed to obtain a copper ferrite / carbon nanofiber film. Wherein, the polymer is polyacrylonitrile or polyvinylpyrrolidone, and the molar ratio of copper salt to iron salt is 1.8-2.2:1.

[0018] The polymer polyacrylonitrile (PAN) or polyvinylpyrrolidone (PVP) is used as a carbon nanofiber precursor, N,N-dimethylformamide is used as an auxiliary agent, and the electrospinning solution is mixed with copper salt and iron salt. The porous copper ferrite / carbon nanofiber membrane is prepared by electrospinning technology combined with carbonization treatment or high-temperature calcination. Elect...

Embodiment 1

[0041] This embodiment provides a copper ferrite / carbon nanofiber film, which is mainly prepared by the following steps:

[0042] Accurately weigh 1.6g of polyacrylonitrile (PAN) and 14.4g of N,N-dimethylformamide (DMF) in a conical flask, put it on a stirrer, and make PAN in DMP under the condition of 50°C Dissolve slowly in medium and turn off the heat setting once dissolved.

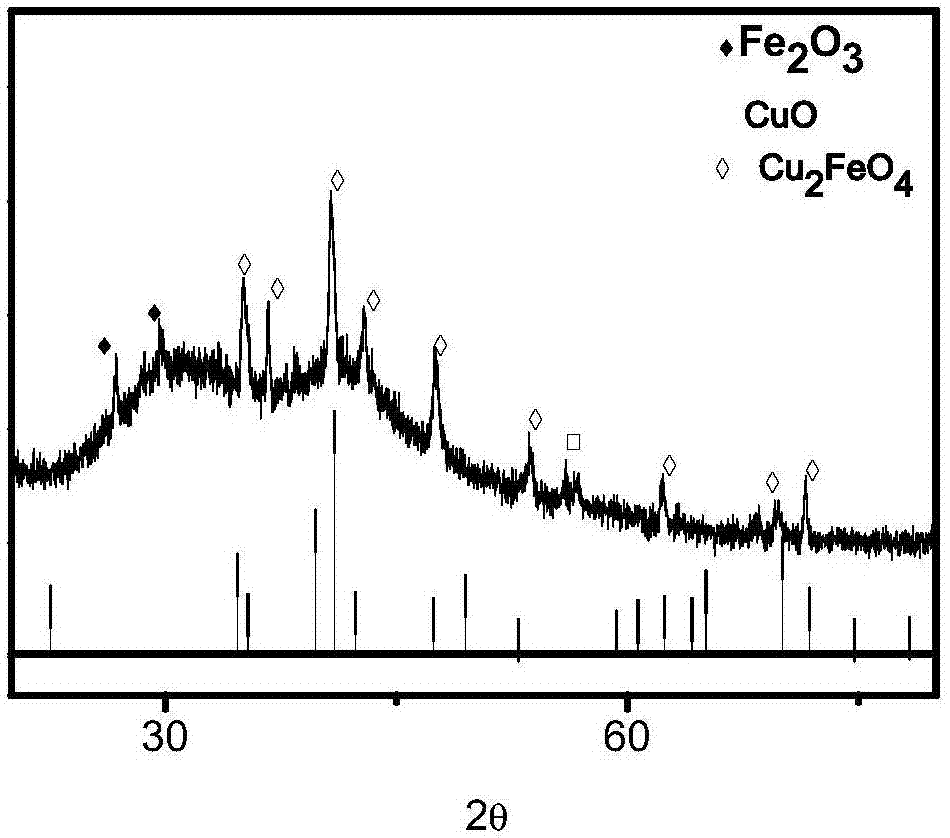

[0043] Add 1.16g of iron acetylacetonate and 0.43g of copper acetylacetonate to the dissolved solution and continue stirring. The obtained copper ferrite / polyacrylonitrile fiber membrane was dried in a vacuum oven after electrospinning. The dried copper ferrite / polyacrylonitrile fiber membrane was heat-treated at 280° C. for 2 h in a muffle furnace, and finally annealed at 720° C. for 1 h under a nitrogen atmosphere to obtain a copper ferrite / carbon nanofiber membrane.

Embodiment 2

[0045] This embodiment provides a copper ferrite / carbon nanofiber film, which is mainly prepared by the following steps:

[0046] Accurately weigh 1.6g of PAN and 14.4g of DMF in a Erlenmeyer flask, place it on a stirrer, and slowly dissolve PAN in DMP at 50°C, and turn off the heating setting after dissolution.

[0047] Add 0.696g of iron acetylacetonate and 0.261g of copper acetylacetonate to the dissolved solution and continue stirring. The obtained copper ferrite / polyacrylonitrile fiber membrane was dried in a vacuum oven after electrospinning. The dried copper ferrite / polyacrylonitrile fiber membrane was heat-treated at 280° C. for 2 h in a muffle furnace, and finally annealed at 680° C. for 1 h under a nitrogen atmosphere to obtain a copper ferrite / carbon nanofiber membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com