A kind of high-efficiency solar nitrogen fixation photocatalytic material and preparation method thereof

A technology of photocatalytic materials and solar energy, which is applied in the field of high-efficiency solar nitrogen fixation photocatalytic materials and its preparation, can solve the problems of high photogenerated carrier recombination rate, low quantum efficiency, and low solar energy utilization rate, and achieve high photocatalytic nitrogen fixation activity, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dissolve 1.2mmoL sodium oleate in 20mL deionized water, add 0.194g Bi(NO 3 ) 3 ·5H 2 O, magnetically stirred for 1.5 hours to form an emulsion precursor solution;

[0039] Dissolve 0.4mmoL ammonium metavanadate in 20mL deionized water, stir for 1 hour and ultrasonically disperse evenly;

[0040] The two groups of solutions were mixed and stirred for 1 hour, then transferred to a 50 mL hydrothermal kettle, hydrothermally reacted at 105°C for 16 hours, and cooled naturally to room temperature;

[0041] The solid sample in the hydrothermal kettle is washed with n-hexane, ethanol, etc., and then the powder is obtained by vacuum freeze-drying technology, which is BiO / BiVO 4 composite material.

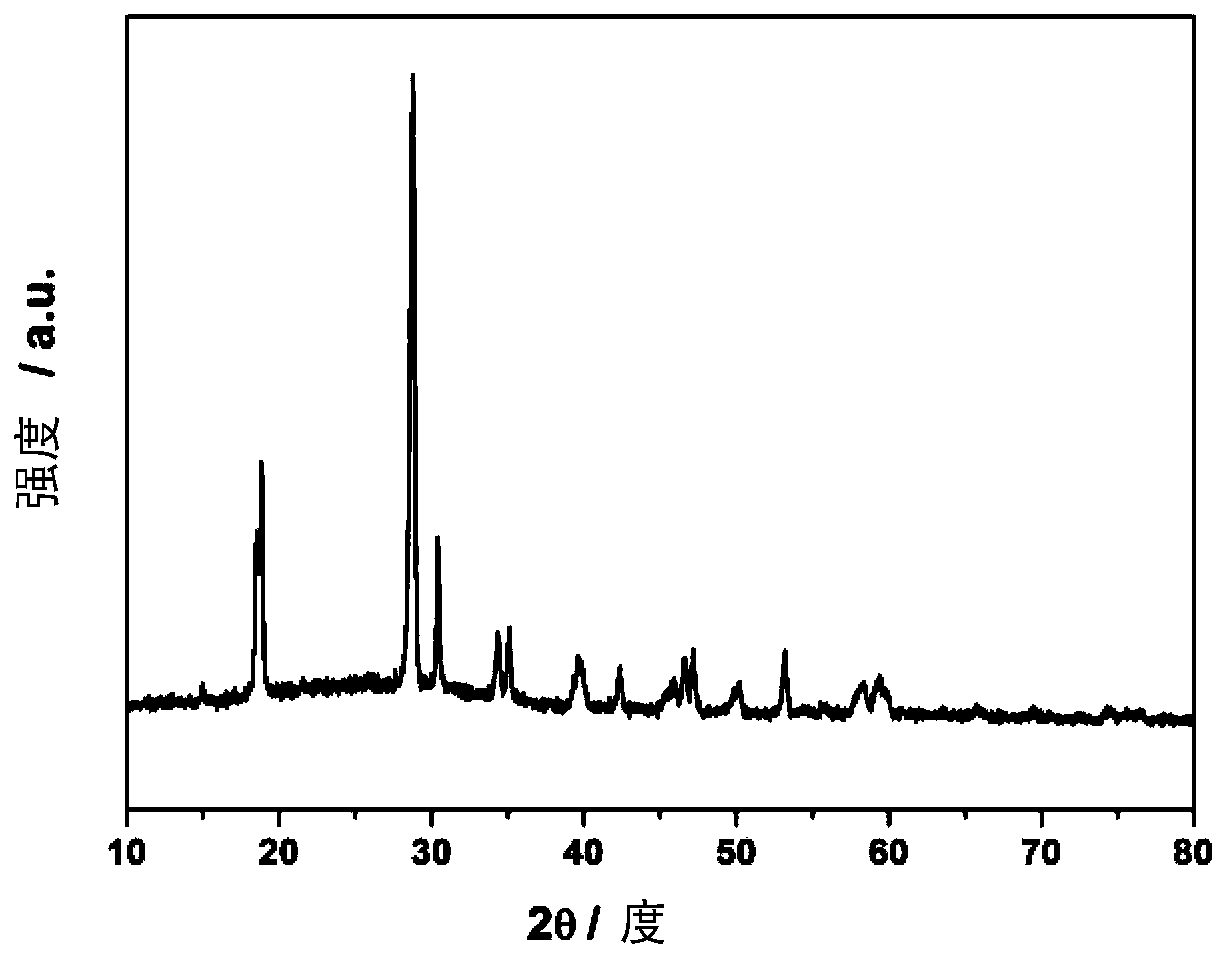

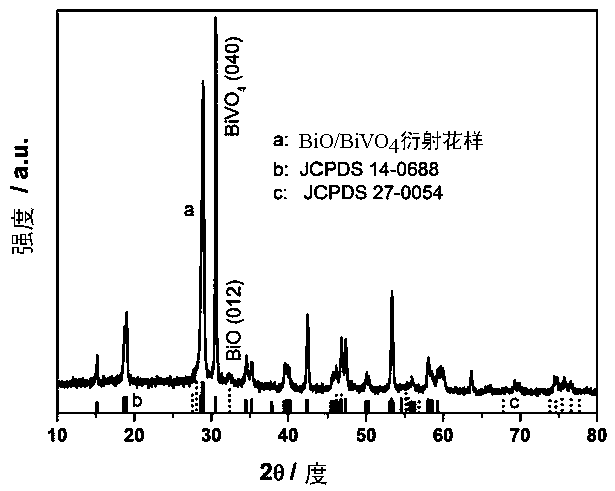

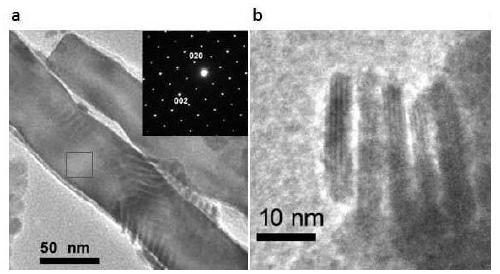

[0042] figure 1 It is the BiO / BiVO obtained in this embodiment 4 The XRD diffraction pattern of the composite material, the XRD component analysis shows that: the obtained composite photocatalytic material is a monoclinic phase BiVO 4 BiO with a small amount of hexagonal phase...

Embodiment 2

[0050] Dissolve 2.2mmoL sodium oleate in 20mL deionized water, add 0.194g Bi(NO 3 ) 3 ·5H 2 O, magnetically stirred for 1.5 hours to form an emulsion-like precursor solution, added 20 mL of deionized water to the precursor solution, then transferred to a 50 mL hydrothermal kettle, reacted at 105 ° C for 20 hours, and cooled naturally to room temperature;

[0051] The solid sample is washed with ethanol, etc., and then the powder is obtained by vacuum freeze-drying technology, which is the BiO material.

[0052] Known through XRD detection analysis (see Figure 4 ): The material obtained in this embodiment is a BiO material (quantum sized BiO (quantum sized BiO)).

[0053] Compared with the composite material obtained in Example 1, the BiO material obtained in this example reduces nitrogen in air to produce NH under the same conditions. 4 + is slightly less efficient (see image 3 ).

Embodiment 3

[0055] Dissolve 1.2mmoL sodium oleate in 20mL deionized water, add 0.194g Bi(NO 3 ) 3 ·5H 2 O, magnetically stirred for 1.5 hours to form an emulsion precursor solution;

[0056] Dissolve 0.1mmoL sodium tungstate in 20mL deionized water, stir for 1 hour and ultrasonically disperse evenly;

[0057] The two groups of solutions were mixed and stirred for 1 hour, then transferred to a 50 mL hydrothermal kettle, hydrothermally reacted at 105°C for 16 hours, and cooled naturally to room temperature;

[0058] The solid sample in the hydrothermal kettle is washed by n-hexane, ethanol, etc., and then the powder is obtained by vacuum freeze-drying technology, which is BiO, Bi 2 o 3 , Bi 2 o 2.33 / Bi 2 WO 6 composite material.

[0059] The Bi obtained in this example 2 o 3-x Composite Bi 2 WO 6 The photocatalytic material obtains BiO / BiVO under the same conditions as in Example 1 4 The photocatalytic nitrogen fixation efficiency of the material is 85% of that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com