BiOCl/MoO2 composite catalyst as well as preparation method and application thereof

A composite catalyst and mixed solution technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, preparation/separation of ammonia, etc., can solve problems such as poor adsorption and activation capacity, high energy consumption of CO2, and low utilization rate, and achieve Easy large-scale production, good feasibility and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

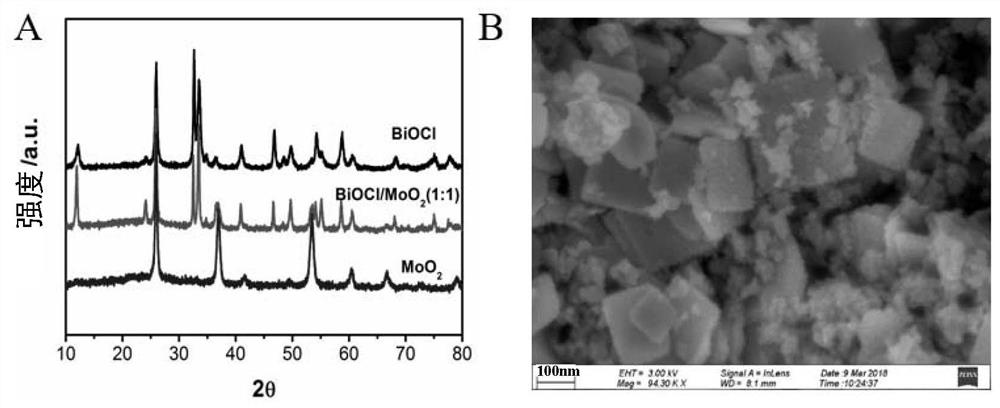

[0034] Preparation of BiOCl nanosheets. Dissolve a certain amount of mannitol in deionized water, stir evenly, and then add a certain amount of Bi(NO 3 ) 3 , stir evenly, and finally add saturated KCl solution dropwise. The obtained mixed solution is then transferred to a hydrothermal kettle, heated at 100-200° C. for 4-24 hours, then cooled, washed and dried to obtain BiOCl nanosheets. Wherein, the volume of mannitol may be 5-50ml. Bi(NO 3 ) 3 The quality can be 0.5 ~ 15g. The volume of the saturated KCl aqueous solution may be 5-50 ml. It should be understood that the preparation method of BiOCl nanosheets in the present invention includes but not limited to hydrothermal method and the like.

[0035] MoO 2 Preparation of nanosheets. A certain amount of MoCl 5 Dissolve in ethanol solution, add a certain amount of deionized water and nitric acid solution, stir and mix evenly, transfer to a hydrothermal reaction kettle, heat at 150-200°C for 12-24 hours, cool, wash an...

Embodiment 1

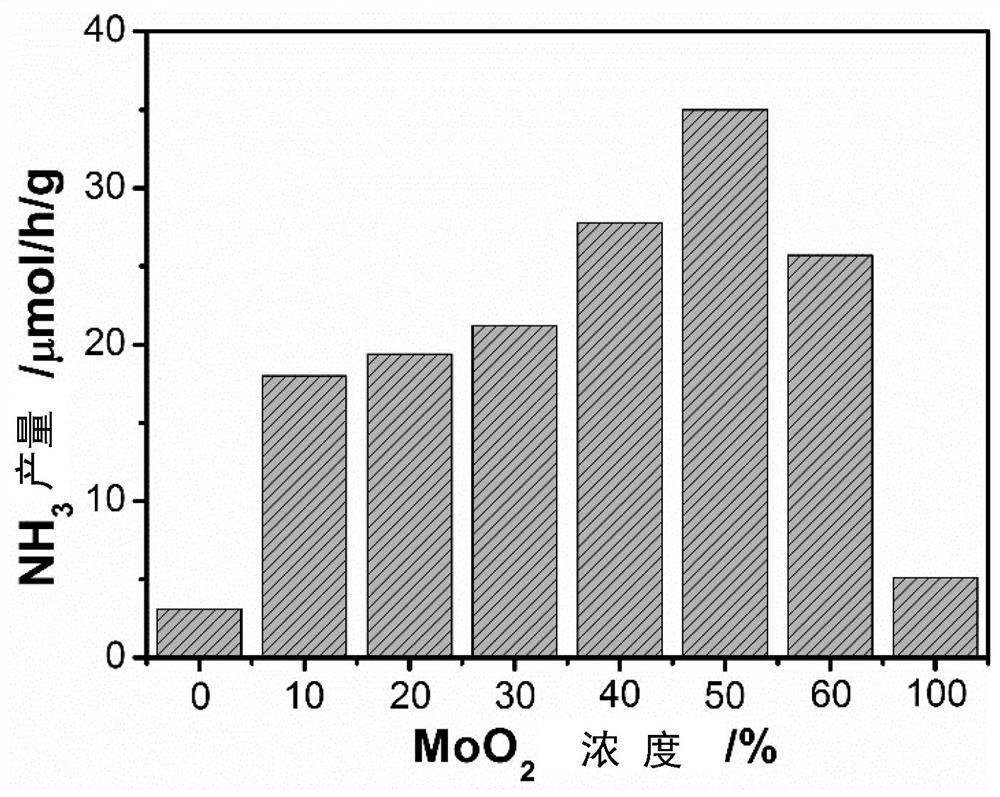

[0053] Example 1: Modification of MoO in different proportions 2 Photocatalytic nitrogen fixation experiment of BiOCl material in aqueous phase

[0054] (1) Dissolve a certain amount of mannitol (0.546g) in deionized water (25ml), stir well, then add a certain amount of Bi(NO 3 ) 3 (0.486g), stir well. Finally, a saturated KCl solution was added dropwise and stirred for 0.5 h to obtain a mixed solution;

[0055] (2) Transfer the resulting mixed solution to a hydrothermal kettle, hydrothermally treat it at 160°C for 4 hours, then cool, wash and dry to obtain BiOCl nanosheets, the size of the BiOCl nanosheets is 0.1-1 μm, and the thickness is 10 ~100nm;

[0056] (3) Then a certain amount of MoCl 5 (0.482g) was dissolved in ethanol solution (8ml), then added a certain amount of deionized water and nitric acid solution (concentration 50wt%, 2ml), stirred and mixed evenly, transferred to a hydrothermal reaction kettle, and hydrothermally treated at 180°C for 12h, Cool, wash a...

Embodiment 2

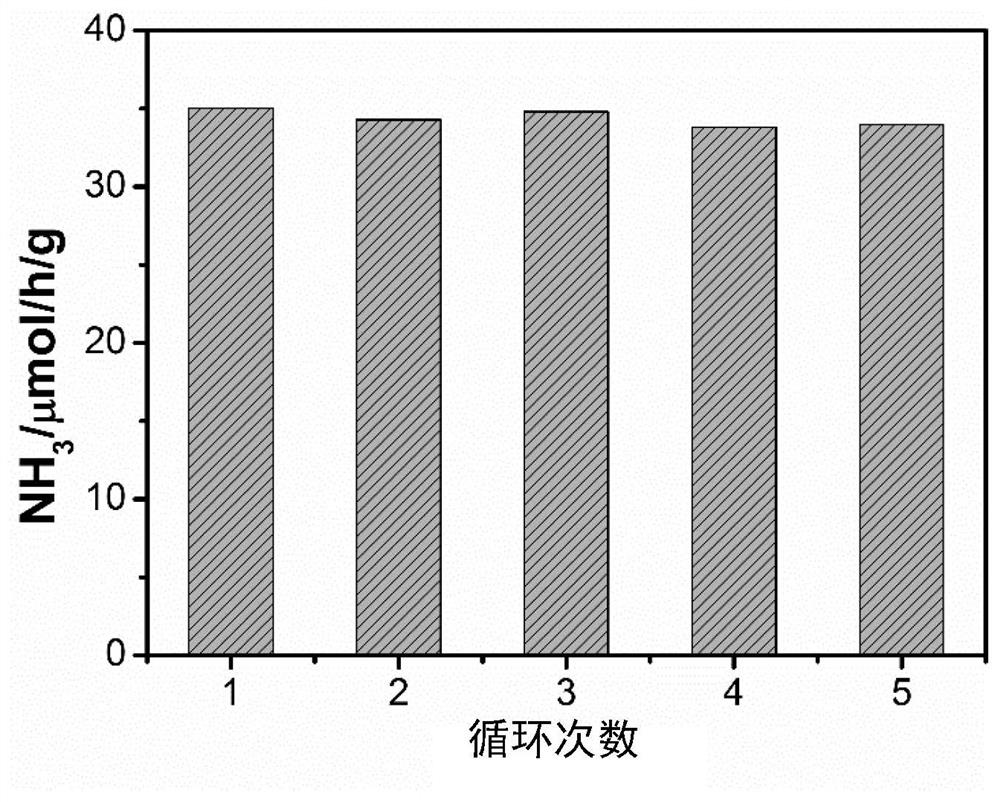

[0063] Example 2: BiOCl / MoO 2 Composite with optimal ratio of BiOCl:MoO 2 =1:1 cyclic nitrogen fixation experiment:

[0064] (1) Preparation of BiOCl / MoO 2 Composite material (with embodiment 1, BiOCl: MoO 2 Mass ratio 1:1);

[0065] (2) The obtained BiOCl / MoO 2 After the composite material is fully ground, take 0.1g of powder and add it to 200mL of water, put it in a 600mL reactor, the reactor is an open system, and stir for 0.5h in the dark to conduct the adsorption-desorption equilibrium experiment;

[0066] (3) Turn on the xenon lamp and illuminate for 1 hour under the simulated sunlight light source;

[0067] (4) Suction filtration, take 50mL of filtrate and put it in a colorimetric tube, add 1mL of potassium sodium tartrate and 1mL of Nessler's reagent, shake well, let it stand for 10-15min, wait for the color development to stabilize, and use a UV spectrophotometer to detect the ammonia production;

[0068] (5) the resulting BiOCl / MoO 2 Repeat steps (2)-(4) for c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com