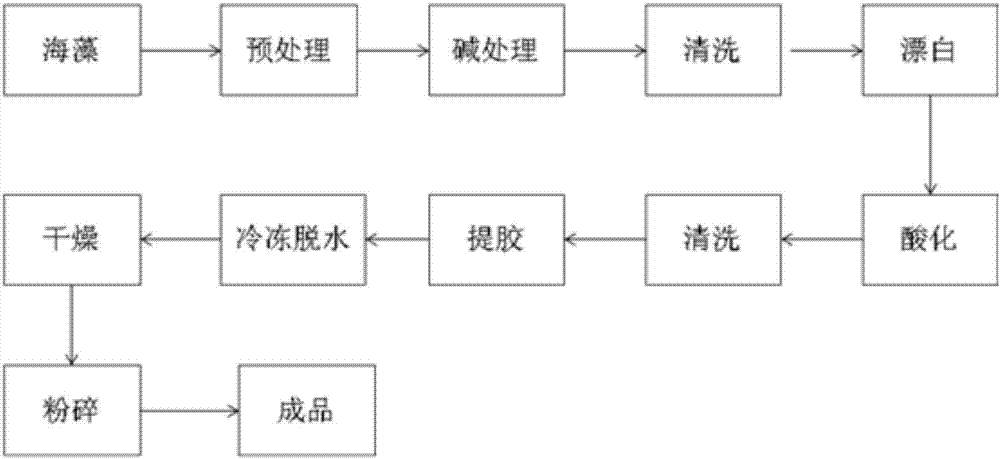

Production process of refined low-temperature instant agarose

A production process and agarose technology, which are applied in the production process field of refining low-temperature instant agarose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

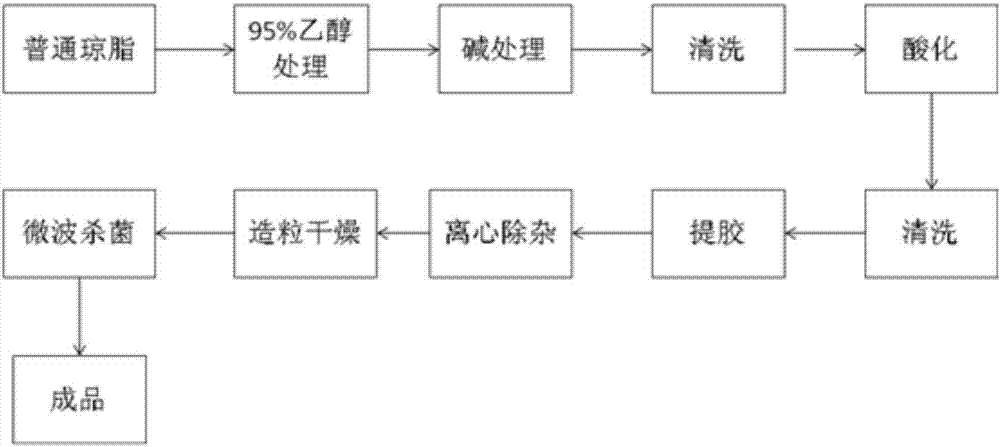

Method used

Image

Examples

example 1

[0059] Example 1: a production process for refining low-temperature instant agarose, which specifically includes the following steps:

[0060] (1) Soak 1kg of common agar in 95% ethanol, 60°C, 90min;

[0061] (2) Place the filtered and dried agar in 6% NaOH solution, the amount of lye is 25L, and heat at 75°C for 90min;

[0062] (3) fully wash the agar with water, after cleaning, wash until the pH is 8.0;

[0063] (4) Put the washed agar in 3% HCl solution, the amount of HCl solution is 25L, stir quickly and fully, and acidify for 30min;

[0064] (5) fully wash the acidified agar with water until the pH is 6.8;

[0065] (6) Agar was extracted in water at 95°C for about 120 minutes, and the water consumption was 50 L;

[0066] (7) After the glue is extracted, centrifuge and filter while it is hot to remove impurities.

[0067] (8) Carry out granulation and drying to the agar solution; granulation methods include: spray drying; spray drying tower parameters: feed temperature...

example 2

[0069] Example 2: a production process for refining low-temperature instant agarose, which specifically includes the following steps:

[0070] (1) Soak 1kg of ordinary agar in 95% ethanol, 50°C, 120min;

[0071] (2) Put the filtered and dried agar in 4% NaOH solution, the amount of lye is 30L, and heat at 80°C for 120min;

[0072] (3) Fully wash the agar with water until the pH is 8.5;

[0073] (4) Place the washed agar in 2% HCl solution, the amount of HCl solution is 30L, stir rapidly and fully, and acidify for 40min;

[0074] (5) fully wash the acidified agar with water until the pH is 7.2;

[0075] (6) Agar was extracted in water at 90°C for about 120 minutes, and the water consumption was 40 L;

[0076] (7) After the glue is extracted, centrifuge and filter while it is hot to remove impurities.

[0077] (8) The agar solution is granulated and dried; the granulation method includes: spray drying; spray drying tower parameters: feed temperature 90°C, inlet air temperatu...

example 3

[0079] Example 3: Application of Low Temperature Instant Agar in Flavored Fermented Milk

[0080] Add 0.1-0.3% low-temperature instant agar to the application of flavored fermented milk, and observe the difference between the experimental group and the blank control group; it is found that the flavored fermented milk with agar added: (1) Good taste, smooth, refreshing, Good melting in the mouth and strong sense of reality; (2) good flavor release without masking the flavor release of the product itself; (3) strong water retention and less centrifugation water; (4) its viscosity changes at low temperature and normal temperature Small and stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com