Method for enhancing yellow emission intensity of YAG: Ce fluorescent powder

A technology of emission intensity and fluorescent powder, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of low yellow light emission intensity of YAG:Ce phosphor, and achieve remarkable technological progress, excellent spectral properties, and strong yellow light emission intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

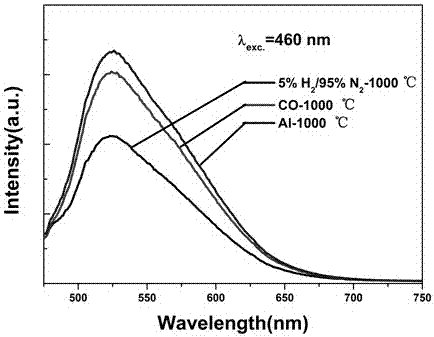

[0012] Weigh 0.3g of Al powder and 3g of YAG:Ce powder according to the mass ratio of Al powder to YAG:Ce powder of 0.1:1, place them in a crucible boat respectively, and place them in a tube furnace in parallel to the left and right (Al powder and YAG :Ce placed separately, always separated, without contact, and the distance between the mutual centers of the crucible boats does not exceed 10 cm), the whole system is evacuated to less than 0.1MPa, heat treatment at 1000°C, after reduction for 8 hours, naturally cool To room temperature, take out the treated YAG:Ce sample. Use a fluorescence spectrometer (HITACHIF-7000) to test its luminous intensity, under the same test conditions, the YAG prepared by the present invention: Ce powder is 5%H 2 -95%N 2 , CO reducing agent to prepare YAG:Ce powder can emit 1.5 times and 1.1 times the intensity (such as figure 1 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com