Detection and quantitative analysis method for compressed air leakage of air-jet loom and detection device

A leak detection device, a technology for compressed air, applied in looms, textiles and papermaking, gas/liquid distribution and storage, etc., can solve problems such as compressed air transmission leakage, and achieve the effect of increasing profits, improving energy conservation awareness, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

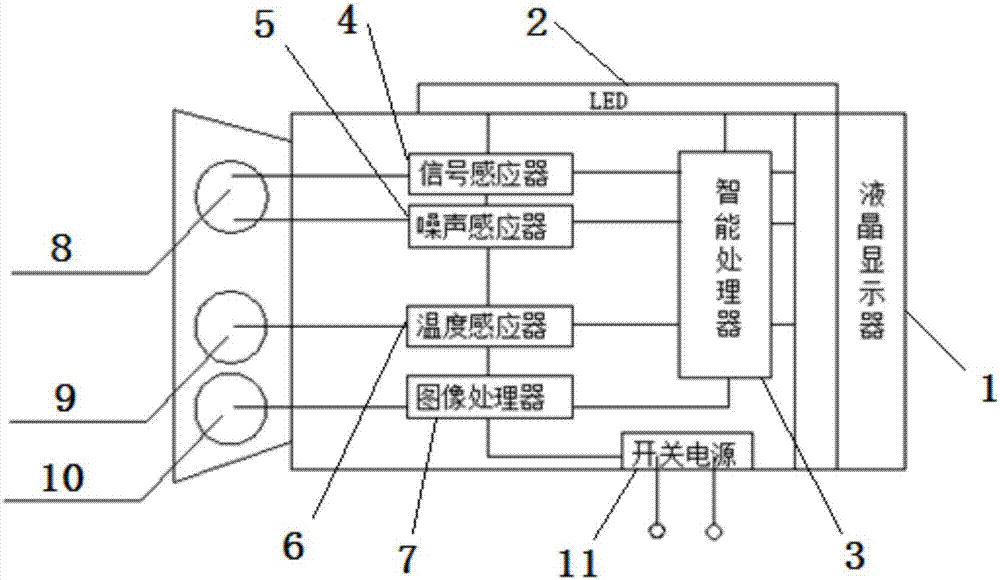

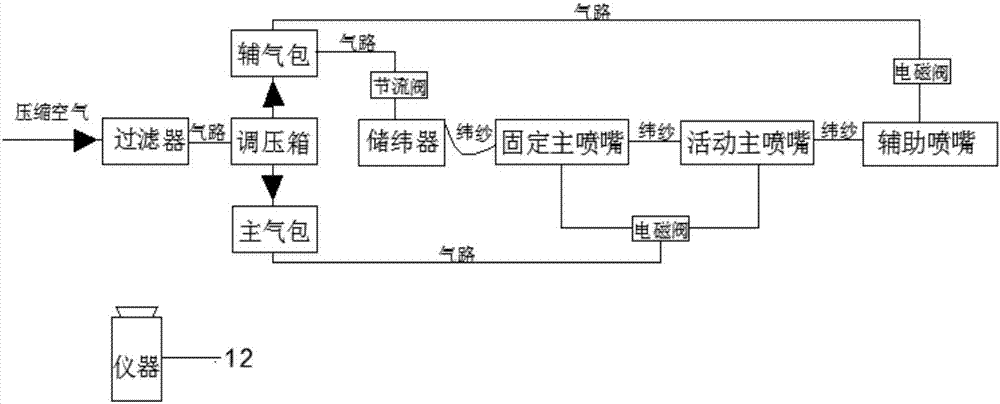

[0043] The air-jet loom compressed air leakage detection and quantitative analysis method of the present invention utilizes an ultrasonic wave and an infrared thermal imager to detect and quantify the leakage, and the detection device 12 adopted is as follows: figure 1 As shown, it includes display part, processing part, detection part and switching power supply 11.

[0044] The display part includes a liquid crystal display 1 and an LED display board 2. The liquid crystal display 1 is used to display the temperature and noise distribution of the leakage surface, and the LED display board 2 displays the leakage situation by the number of light columns.

[0045] The processing part includes an intelligent processor 3 and an image processor 7 , and the detection part includes a signal sensor 4 , a noise sensor 5 , a temperature sensor 6 , an ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com