'Increasing, returning, reducing, combining' carbon-fixing and discharge-reducing fertilizing method in Allium fistulosum and wheat crop rotation

A fertilization method and carbon emission reduction technology, applied in fertilization methods, fertilization devices, botanical equipment and methods, etc., can solve the problems of unreasonable fertilizer management, nutrient loss, aggravation of crop diseases and insect pests, etc., to improve soil physical and chemical properties, increase The effect of reducing soil organic matter and total nitrogen leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

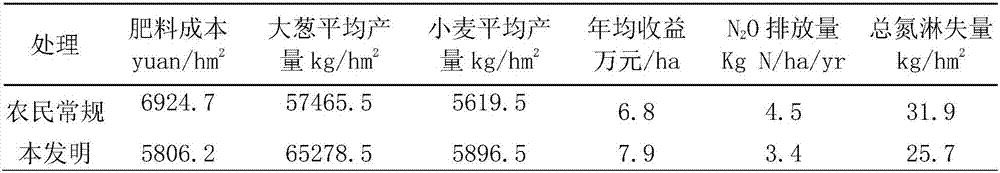

Examples

Embodiment 1

[0049] The green onion-wheat rotation "increase, return, decrease, combine" carbon sequestration and emission reduction fertilization method of the present invention comprises the following steps:

[0050] 1) In mid-June, during the wheat harvesting process, the wheat straw was crushed with a harvester, so that the wheat straw could be crushed and returned to the field on the spot. After wheat straw is harvested, the soil is plowed in time to prevent the straw from being exposed to the surface and be dried in the sun, and to promote the rapid decomposition of the straw.

[0051] Adopting the method of plowing and “returning” wheat straw to the field in full after crushing wheat straw, on the one hand, it makes wheat straw resourceful and fertilized, prevents straw burning from the source, ensures the recycling of resources and avoids economic and environmental losses caused by straw burning , On the other hand, it can also increase soil organic matter, improve soil aggregate s...

Embodiment 2

[0061] The green onion-wheat rotation "increase, return, decrease, combine" carbon sequestration and emission reduction fertilization method of the present invention comprises the following steps:

[0062] 1) In mid-June, during the wheat harvesting process, the wheat straw was crushed with a harvester, so that the wheat straw could be crushed and returned to the field on the spot. After wheat straw is harvested, the soil is plowed in time to prevent the straw from being exposed to the surface and be dried in the sun, and to promote the rapid decomposition of the straw.

[0063] Adopting the method of plowing and “returning” wheat straw to the field in full after crushing wheat straw, on the one hand, it makes wheat straw resourceful and fertilized, prevents straw burning from the source, ensures the recycling of resources and avoids economic and environmental losses caused by straw burning , On the other hand, it can also increase soil organic matter, improve soil aggregate s...

Embodiment 3

[0073] The green onion-wheat rotation "increase, return, decrease, combine" carbon sequestration and emission reduction fertilization method of the present invention comprises the following steps:

[0074] 1) In mid-June, during the wheat harvesting process, the wheat straw was crushed with a harvester, so that the wheat straw could be crushed and returned to the field on the spot. After wheat straw is harvested, the soil is plowed in time to prevent the straw from being exposed to the surface and be dried in the sun, and to promote the rapid decomposition of the straw.

[0075] The method of plowing and “returning” wheat straw to the field after crushing the whole amount of wheat straw can, on the one hand, turn wheat straw into a resource and fertilizer, prevent straw burning from the source, ensure the recycling of resources and avoid economic and environmental losses caused by straw burning , On the other hand, it can also increase soil organic matter, improve soil aggrega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com