A kind of formula and production process of noodles for burning noodles

A production process and noodle technology, which is applied in the processing, application, and bakery of dough, etc., can solve the problems of affecting the taste, easy gelatinization of noodles, and can only be cooked and eaten immediately. The effect of high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

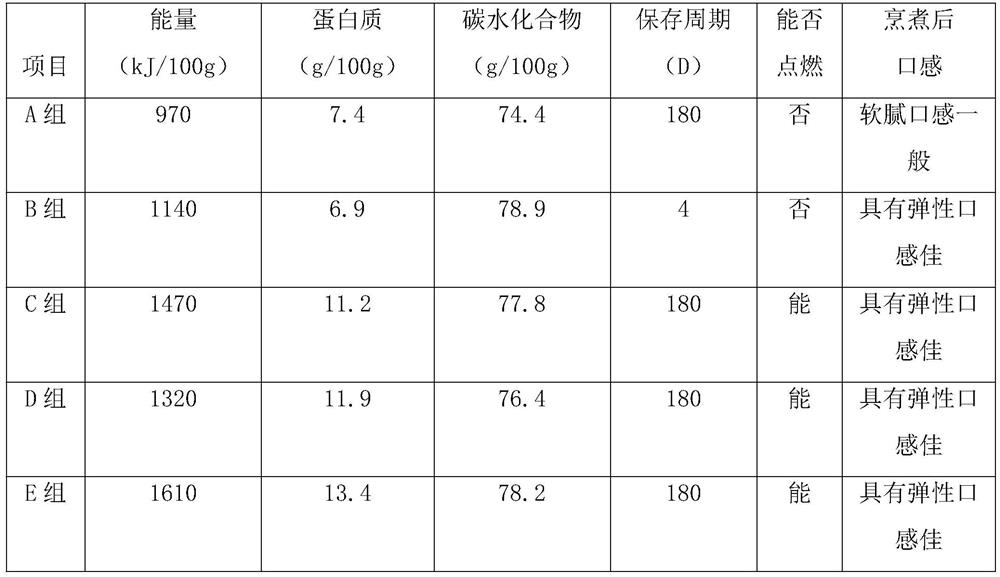

[0037] Take 1kg of dry noodles and 1kg of water noodles sold in the market, and mark them as groups A and B, and count the energy, protein, carbohydrate content, taste after cooking, storage period and whether they can be ignited after cooking in groups A and B.

Embodiment 2

[0039] Follow these steps to make:

[0040] The first step, kneading the dough, mixed 90 parts of wheat flour with 15 parts of drinking water to make a dough, and put the dough to rest for 5 minutes;

[0041] The second step is to make noodles. Put the blanks behind the noodles into a noodle press to make dough skins. Roll the dough skins and cut them into strips to make noodles. Sprinkle 3 parts of cornstarch on the surface of the noodles and place them in the room for ventilation and cooling for 5 minutes;

[0042] The third step is rough processing of noodles. Put the noodles cooled to room temperature into a bamboo steamer, and perform the first steaming and heating. , the steaming temperature is 86°C, the time is 4min, and then heated for the second time, the temperature is 40°C, and the time is 8min. Finally, the noodles are taken out of the bamboo steamer and placed in a bamboo shaker Ventilate and cool on the rack for 10 minutes;

[0043] The fourth step is finishing t...

Embodiment 3

[0046] Follow these steps to make:

[0047] The first step, kneading the dough, mixed 100 parts of wheat flour with 25 parts of drinking water to make a dough, and left the dough to stand for 20 minutes;

[0048] The second step is to make noodles. Put the blanks behind the noodles into a noodle press to make dough skins. Roll the dough skins and cut them into strips to make noodles. Sprinkle 10 parts of cornstarch on the surface of the noodles and place them in the room for ventilation and cooling for 20 minutes;

[0049] The third step is rough processing of noodles. Put the noodles cooled to room temperature into a bamboo steamer, and first heat them for the first time. The temperature for the first time is 85°C, and the time is 10 minutes. , the steaming temperature is 100°C, the time is 10min, and then heated for the second time, the temperature is 80°C, the time is 20min, and finally the noodles are taken out of the bamboo steamer and placed in a bamboo shaker. Ventilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com